Method for testing expansion of anode sheet of lithium ion battery

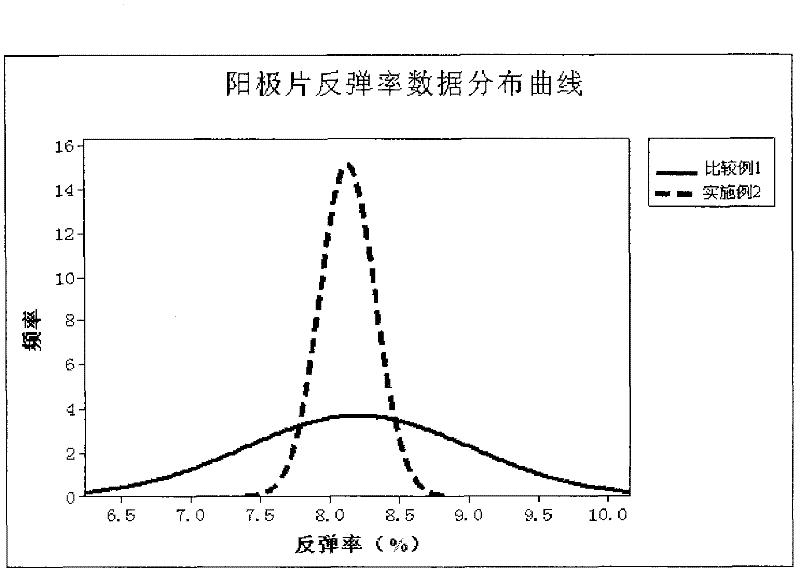

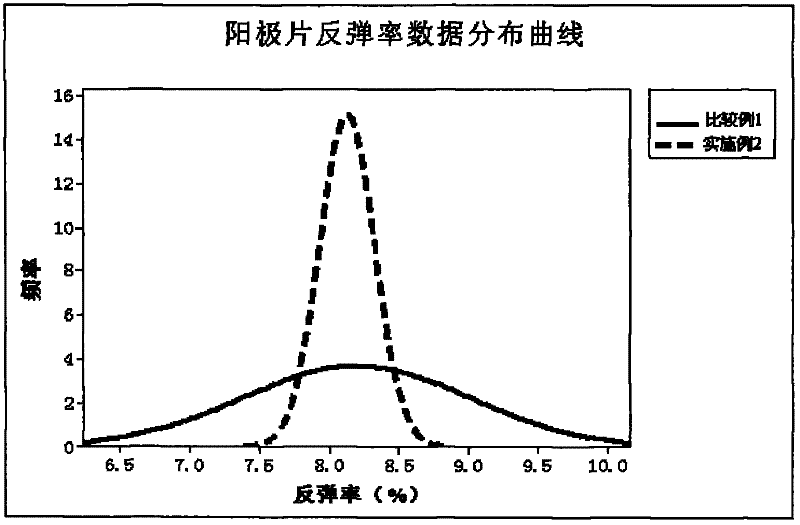

A lithium-ion battery and anode sheet technology, applied in the field of lithium-ion batteries, can solve the problems of inaccurate measurement of the expansion rate of the anode sheet, uneven thickness distribution of the anode sheet, poor data consistency, etc., to achieve easy operation and repeat consistency Good, accurate expansion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Choose one of the anode sheets to be measured, randomly select an anode sheet, and stick a PP-based tape in the middle of the two adjacent cathode sheets. The tape size is a circle with a diameter of D=3.0cm, and then the processed cathode The cell, the anode sheet and the diaphragm are assembled into the cell by the method of lamination, and then put into the packaging bag, inject an appropriate amount of electrolyte, and let it stand for a certain period of time until the electrolyte fully soaks the pole piece, then charge the cell to 3.0V, and then The prepared battery cell is disassembled in the drying room, and the thickness H of the non-expansion zone of the anode sheet is measured with a micrometer S (Corresponding to the cathode sheet has a lithium-ion insulating material PP-based tape) and the expansion area around the non-expansion zone (corresponding to the cathode sheet without lithium-ion insulating material PP-based tape) thickness H Z , The thickness of the ...

Embodiment 2

[0044] Choose one of the anode plates to be measured, remove the cathode coating with nitromethylpyrrolidone at the middle position of the negative plate corresponding to the penultimate layer of the anode plate, the coating removal area is 3.0×3.0cm square, and then process it. The cathode sheet, anode sheet and diaphragm are assembled into a battery cell by winding method, then put into the packaging bag, inject a proper amount of electrolyte, and let it stand for a certain period of time until the electrolyte fully soaks the pole piece, then charge the battery to 3.8V, After that, the prepared battery cell is disassembled in a drying room, and the thickness H of the non-expansion area of the anode sheet is measured with a height gauge. S (Corresponding to the cathode without coating) and the expansion area around the non-expansion zone (corresponding to the cathode with coating) thickness H Z , The thickness of the anode sheet substrate is known to be H A , Anode expansion o...

Embodiment 3

[0051] Choose one of the anode sheets to be measured, and stick a PET-based tape in the middle of the diaphragm corresponding to the second-to-last layer of the anode sheet. The tape shape is an isosceles trapezoid (a (top side length) = 2cm, b (bottom side length)) = 4cm, h (height) = 3cm), then the cathode sheet, anode sheet, and the processed diaphragm are assembled into a battery cell by winding method, and then put into the packaging bag, inject a proper amount of electrolyte, and stand for a certain period of time for electrolysis After the liquid fully soaks the pole pieces, charge the cells to 4.2V, and then select some cells to discharge to 3.0V, then charge to 4.2V and cycle 10 times. After that, the prepared battery cell is disassembled in a drying room, and the thickness H of the non-expanded area of the anode sheet is measured with a micrometer S (Corresponding to the diaphragm with a lithium-ion insulating material PET-based tape) and the non-expansion zone surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com