Subsection type liquid level measuring module

A liquid level measurement, segmented technology, applied in the liquid level indicator of physical variable measurement, etc., can solve the problems that affect the accuracy of the measurement results, affect the service life of the sensor, and are prone to failure, so as to achieve accurate and reliable measurement results , low power consumption, strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

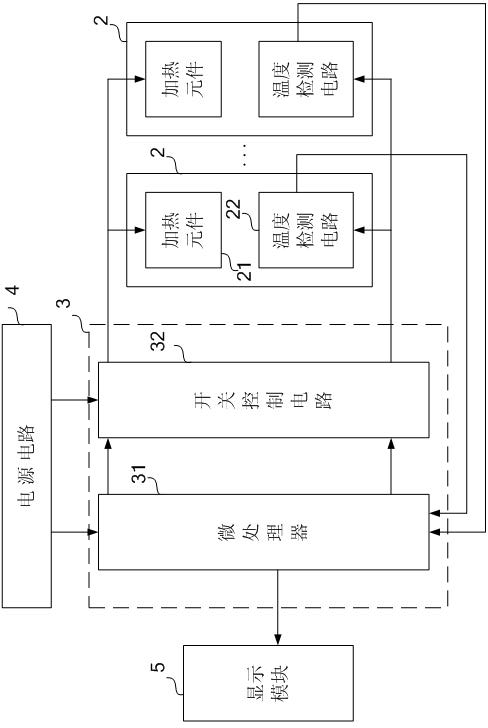

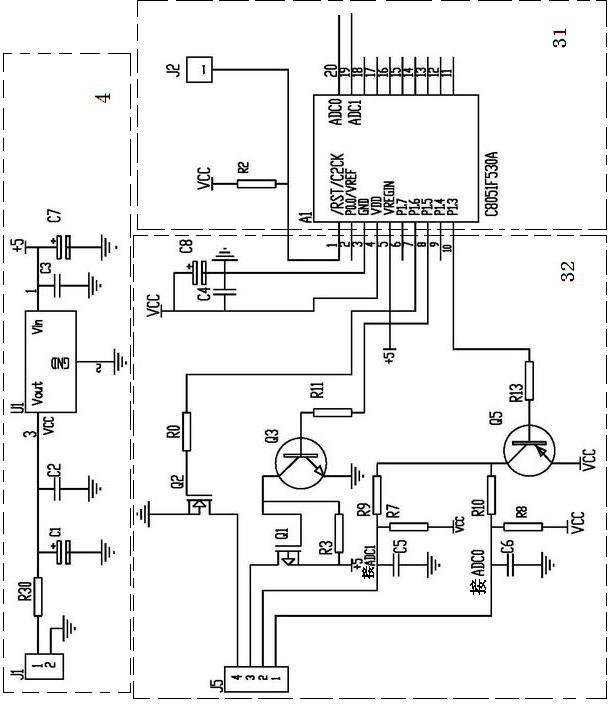

[0016] refer to figure 1 , according to an embodiment of the present invention, the segmented liquid level measurement module includes a probe positioning seat 1 , a plurality of probes 2 , a main control circuit 3 , a power circuit 4 and a display module 5 . A plurality of detection heads means that the number of detection heads is at least two.

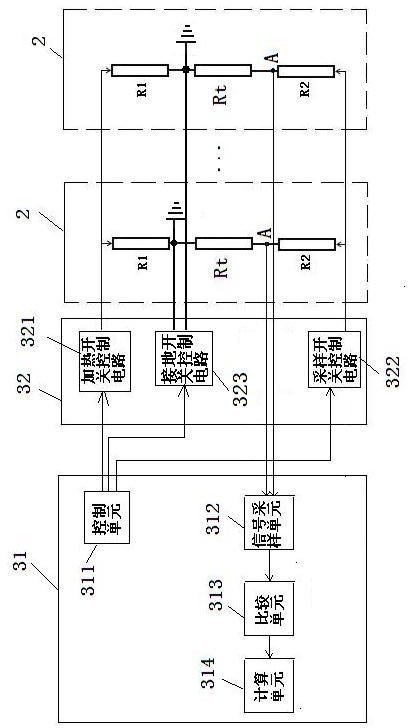

[0017] combine Figure 4 As shown, a plurality of probes 2 are arranged on the probe positioning seat 1 from top to bottom. The probe head is packaged with insulating and heat-conducting solid glue, which can dissipate heat through the heat-conducting solid glue and prevent liquids with strong dielectrics from conducting electricity. exist Figure 4 Six probes are shown in , which is only used as an example, and the number of probes can be changed according to the needs of actual detection.

[0018] Each probe 2 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com