Device and method for measuring effective flow rate and dynamic pressure of grinding fluid

A technology of effective flow and measuring devices, which is applied in the direction of mass flow measuring devices, the measurement of the force of properties using piezoelectric devices, indirect mass flow meters, etc. Problems such as workpiece accuracy and surface quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be described below with reference to the accompanying drawings.

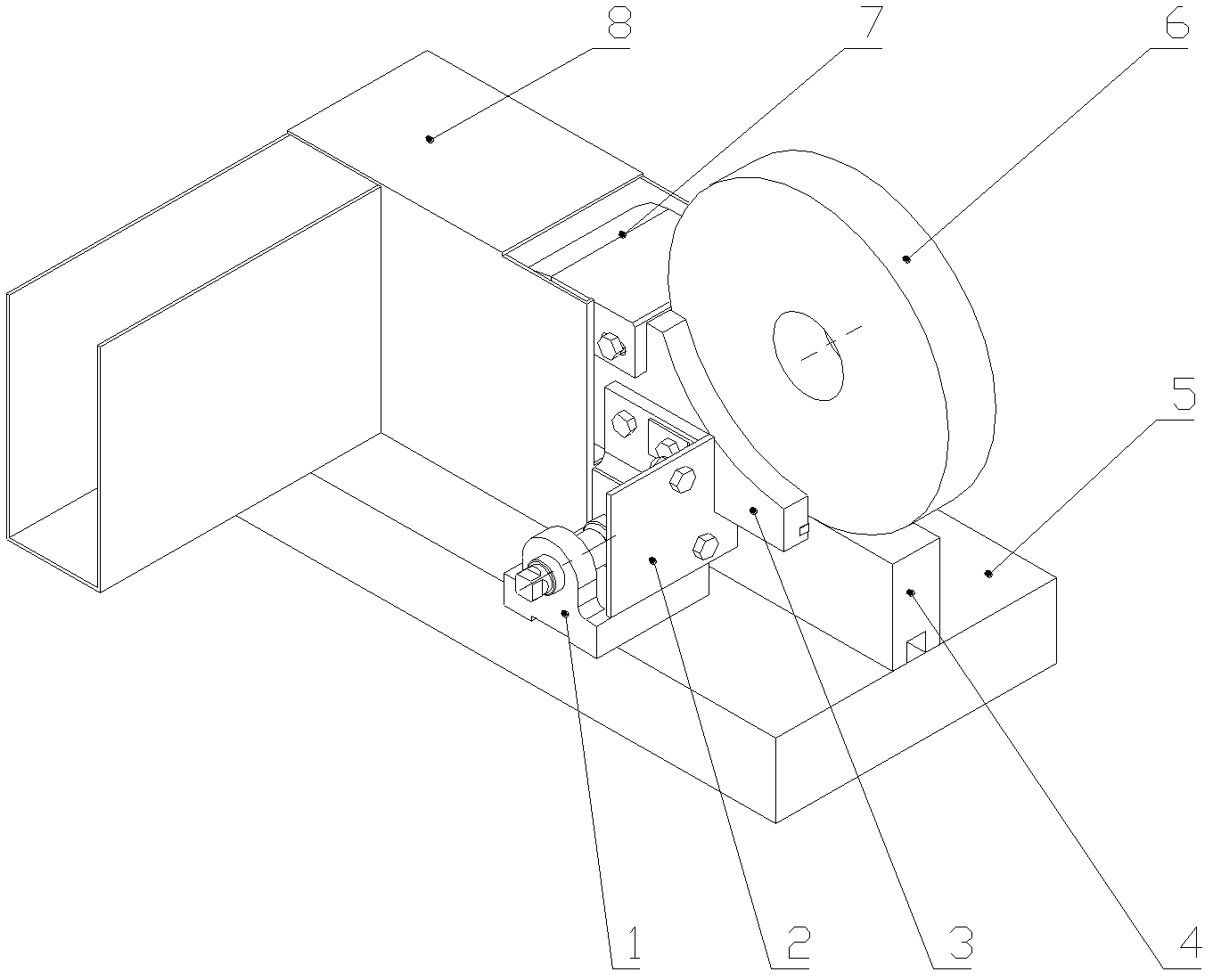

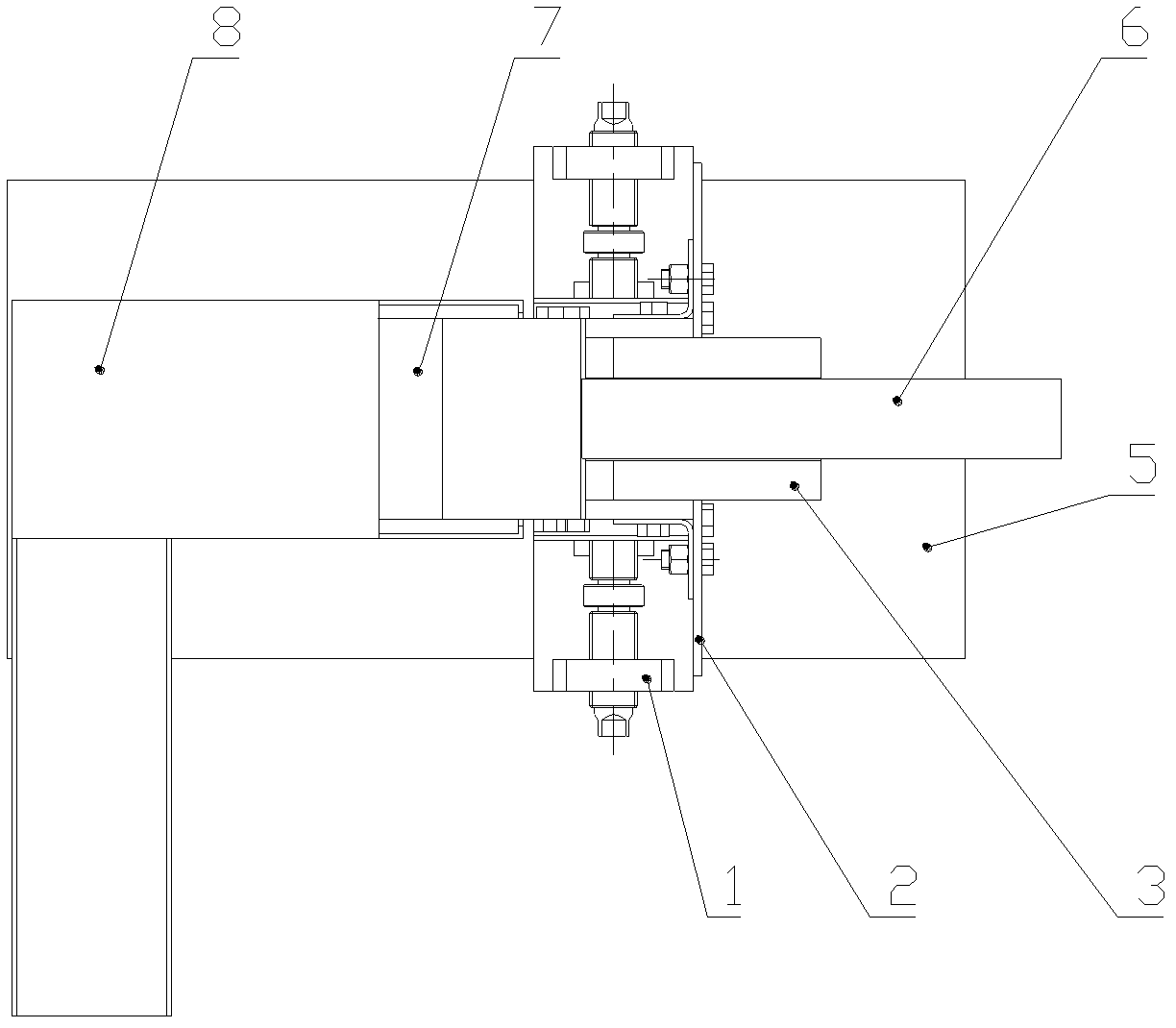

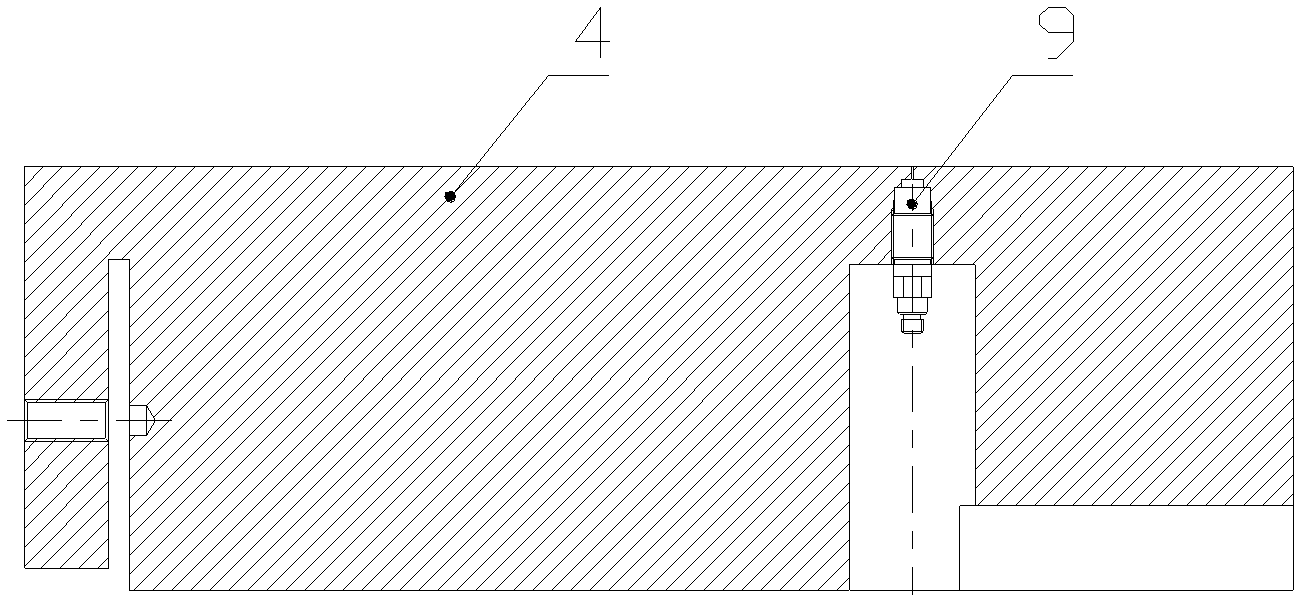

[0086] Depend on figure 1 , 2 , 3, it can be seen that the measuring device for the effective flow rate and dynamic pressure of the grinding fluid is mainly composed of a differential screw mechanism 1, a rubber baffle 2, an effective flow separation plate 3, a workpiece 4, a scraper 7, a collection groove 8 and a piezoelectric In order to measure the effective flow rate of the grinding fluid and the hydrodynamic pressure in the grinding area, the width of the workpiece 4 is equal to the width of the grinding wheel; the effective flow separation plate 3 is fixed on the sliding plate 12 of the differential screw mechanism 1, and is composed of The screw 11 controls the lateral movement of the effective flow separation plate 3 to make it approach or leave the grinding wheel 6; in order to prevent the effective flow passing through the grinding zone from circulating back to the je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com