Equipment installation base with convenience for leveling

A technology for equipment installation and installation grooves, applied in the direction of mechanical equipment, engine frame, special foundation layout, etc., can solve the problems of poor accuracy of construction equipment, inconvenient adjustment, and uneven quality of construction personnel, so as to facilitate adjustment and tightening operations. , The leveling effect is good, and the effect of ensuring the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

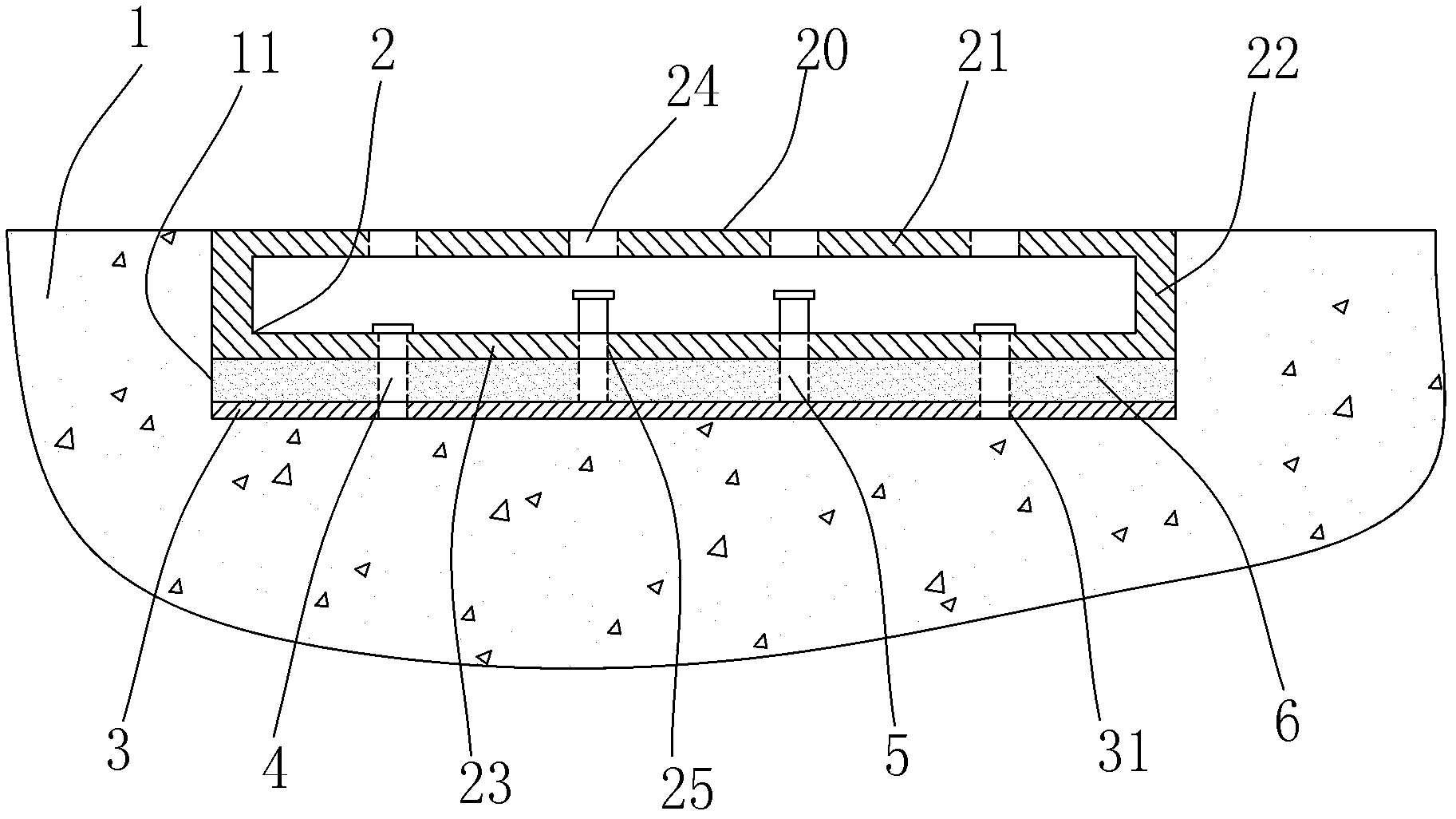

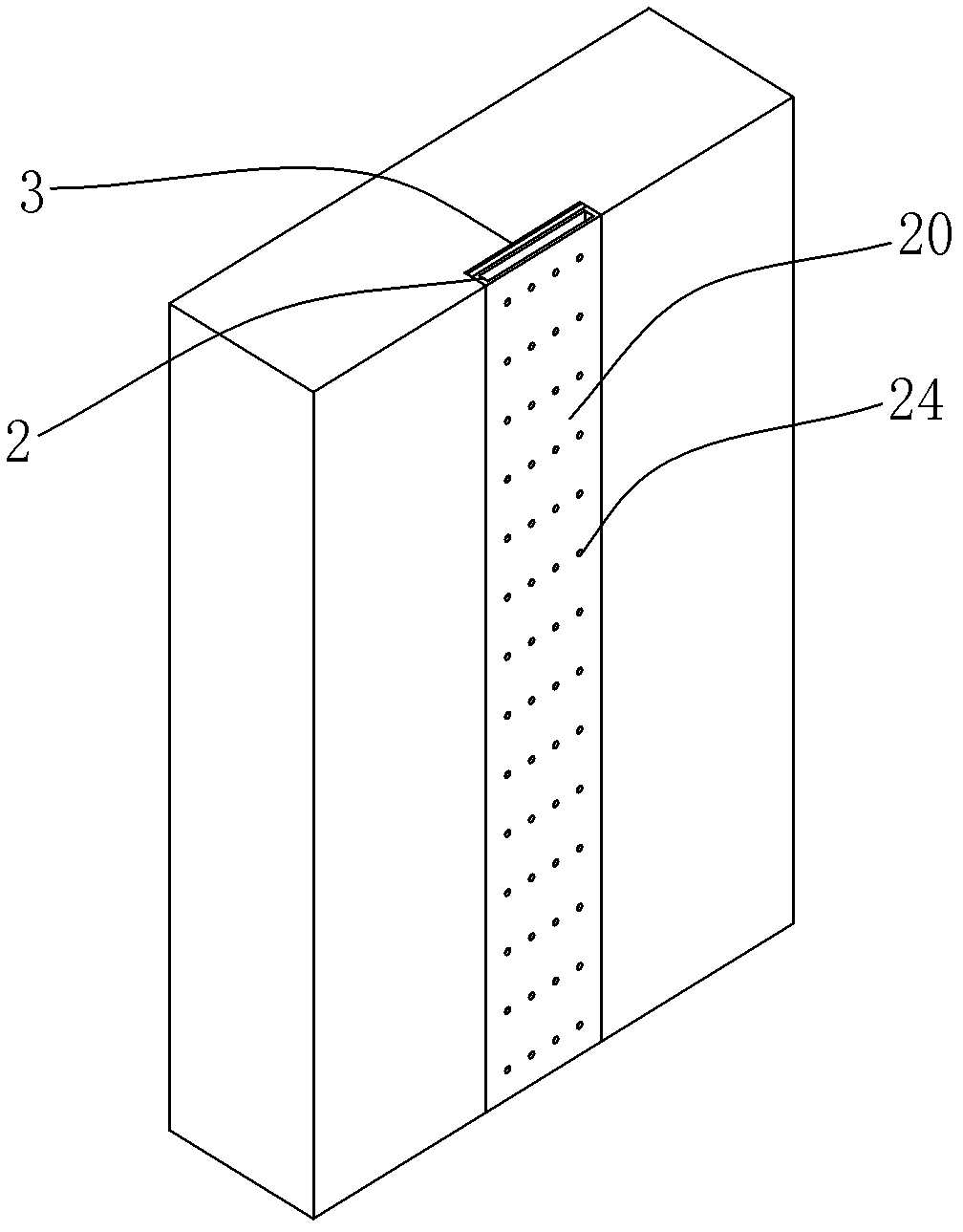

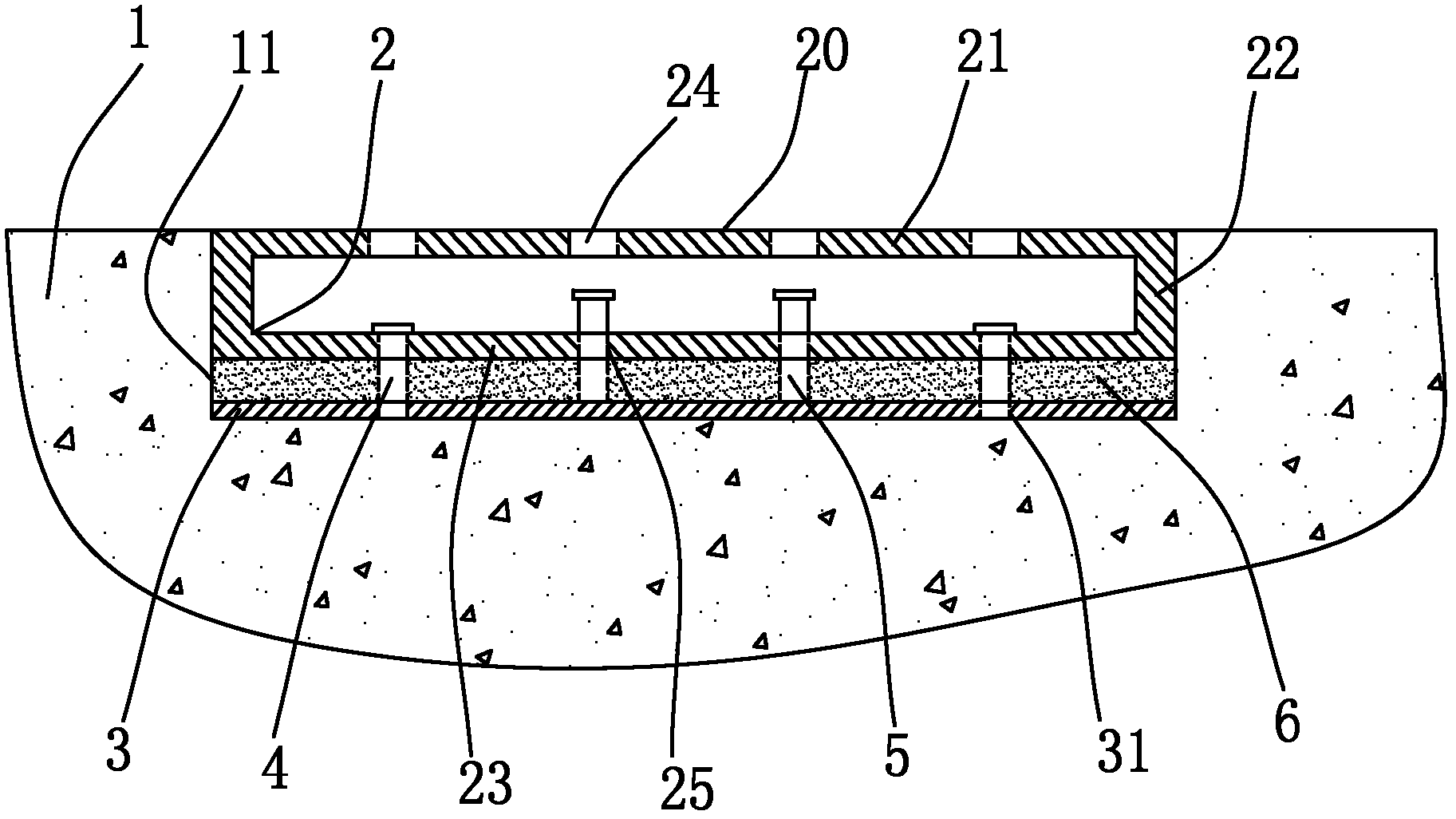

[0015] Such as figure 1 As shown, the equipment installation base for easy leveling of the present invention includes a concrete wall 1, and the concrete wall 1 is provided with an installation groove 11. A substrate steel plate 3 is embedded in the bottom of the installation groove 11, and a steel plate 3 can be accommodated in the installation groove 11. The box girder 2, the box girder 2 is surrounded by an upper plate 21, a lower plate 23 and two side plates 22 to form a box shape, and the lower plate 23 is located above the substrate steel plate and parallel to the substrate steel plate 3.

[0016] The lower plate 23 is provided with a plurality of screw holes 25, and a plurality of adjusting screws 5 and a plurality of fastening screws 4 are respectively installed in these screw holes 25, wherein the lower ends of the adjusting screws 5 pass through the screw holes 25 and push against the substrate steel plate 3, the lower end of the fastening screw 4 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com