Washing machine and method of controlling the same

A washing machine and controller technology, which is applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of deterioration of operating state and difficulty in meeting the degree of washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout.

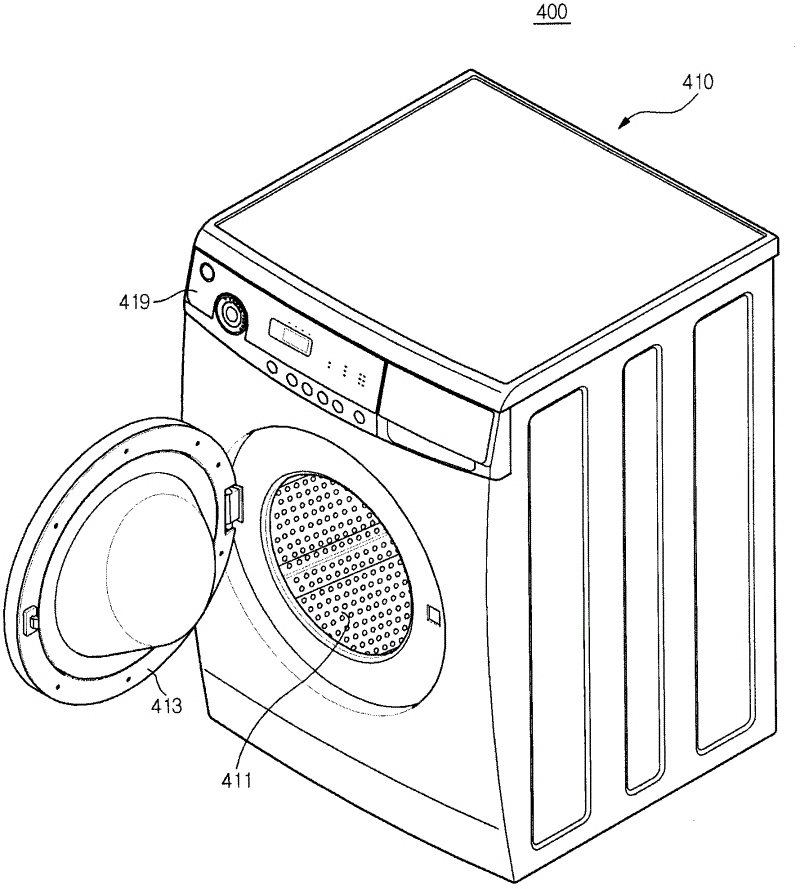

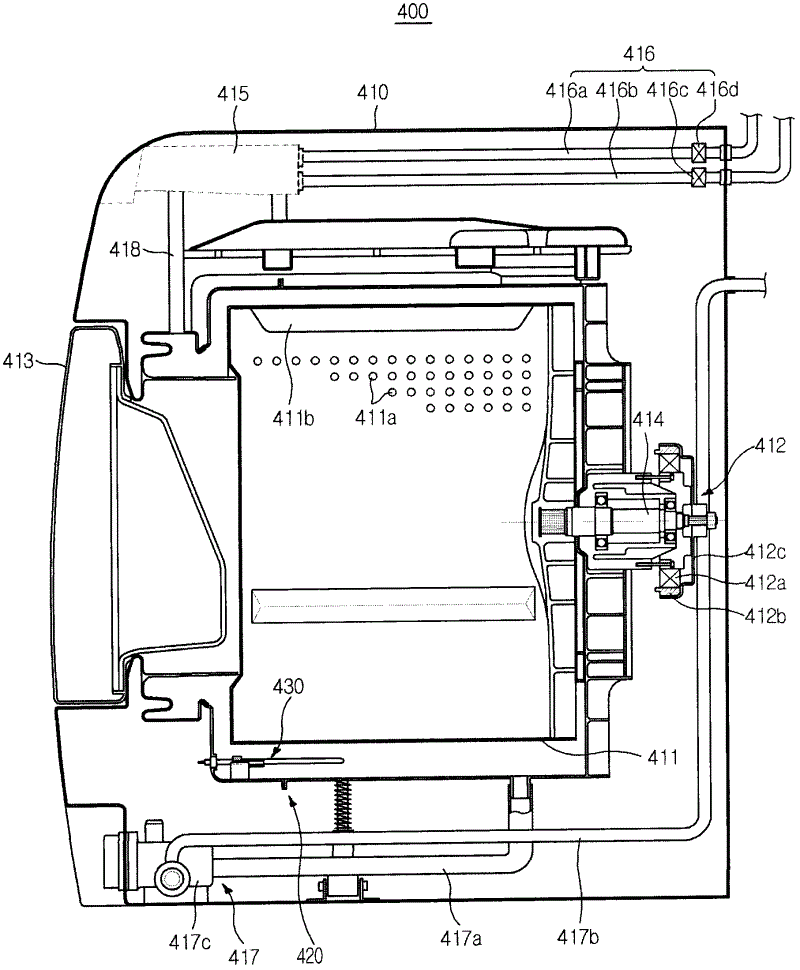

[0052] figure 1 is a block diagram showing a power management system applied to a washing machine according to an embodiment. figure 2 is a perspective view showing a washing machine according to one embodiment. image 3 is a sectional view showing a washing machine according to one embodiment.

[0053] In the following, reference will be made to figure 1 A power management system including an energy management system (EMS) in communication with a washing machine is described.

[0054] refer to figure 1 , the power management system includes a power supplier 100 , a smart meter (smart meter) 200 , an energy management system (EMS) 300 and a washing machine 400 .

[0055] The power provider 100 is an electric power supply source operated by a power supply company (utility company) that gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com