Liquid caustic soda automatic flowing system during production of flake caustic soda

A production process, liquid caustic technology, applied in alkali metal compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as increased maintenance workload, poor operating conditions for workers, and high labor intensity for workers, achieving The effect of avoiding the loss of pot heat temperature difference, high labor intensity and shortening the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments.

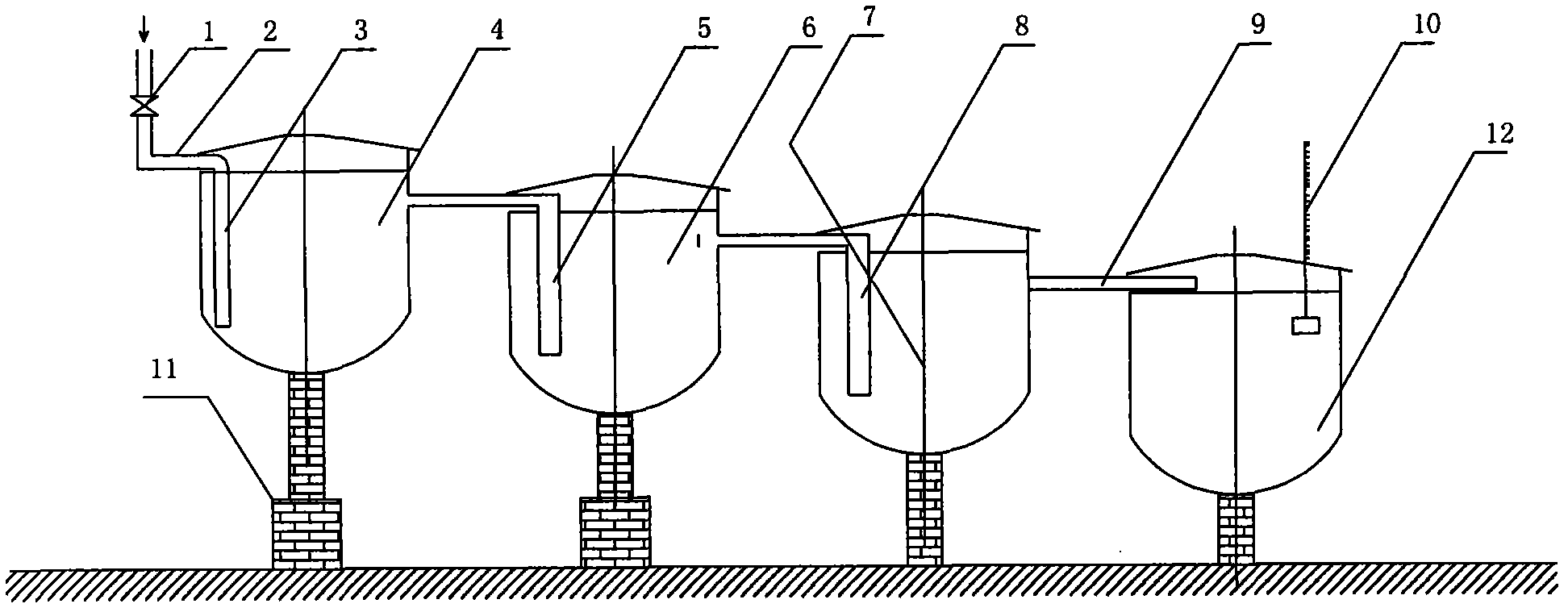

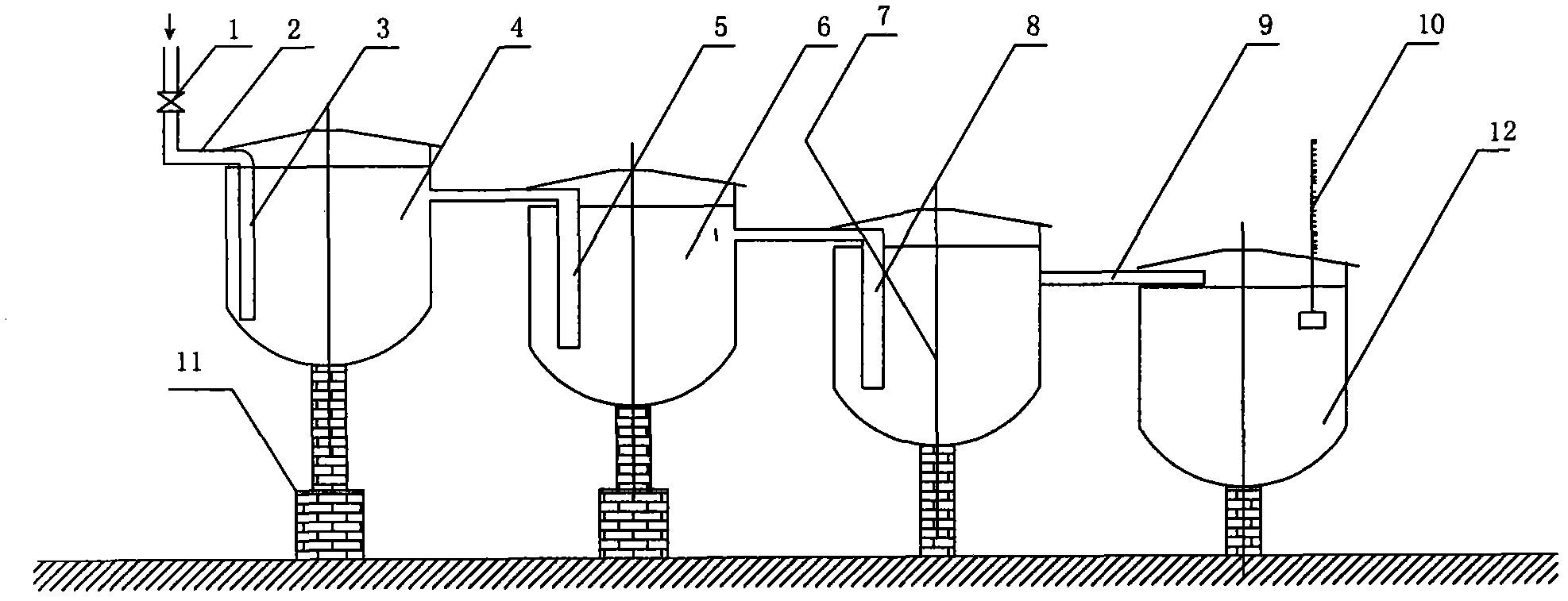

[0031] refer to figure 1 , install the three-level preheating pot 4, the second-level preheating pot 6, and the first-level preheating pot 7 in order from high to low in a ladder shape, and the liquid caustic soda stored in the storage tank (installation position higher than the high level tank) flows automatically to the liquid caustic soda Alkali high-level tank (use the liquid level pressure difference formed by the storage tank and the high-level tank to carry out self-flow step by step), and flow to the control electric valve 1 to adjust the flow rate, and the liquid alkali flows into the third stage through the liquid inlet pipe 2 and the three-stage preheating pot guide tube 3 The bottom of the first-level preheating pot 4, when the liquid is full, flows into the bottom of the second-level preheating pot 6 through the guide tube 5 of the second-level preheating pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com