Rubber sheet winding machine

A winder and thin sheet technology, which is applied in the field of rubber sheet output machine and winder for winding rubber sheet, can solve the problems of poor quality of rubber sheet and lower production efficiency, and achieve the effect of good quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

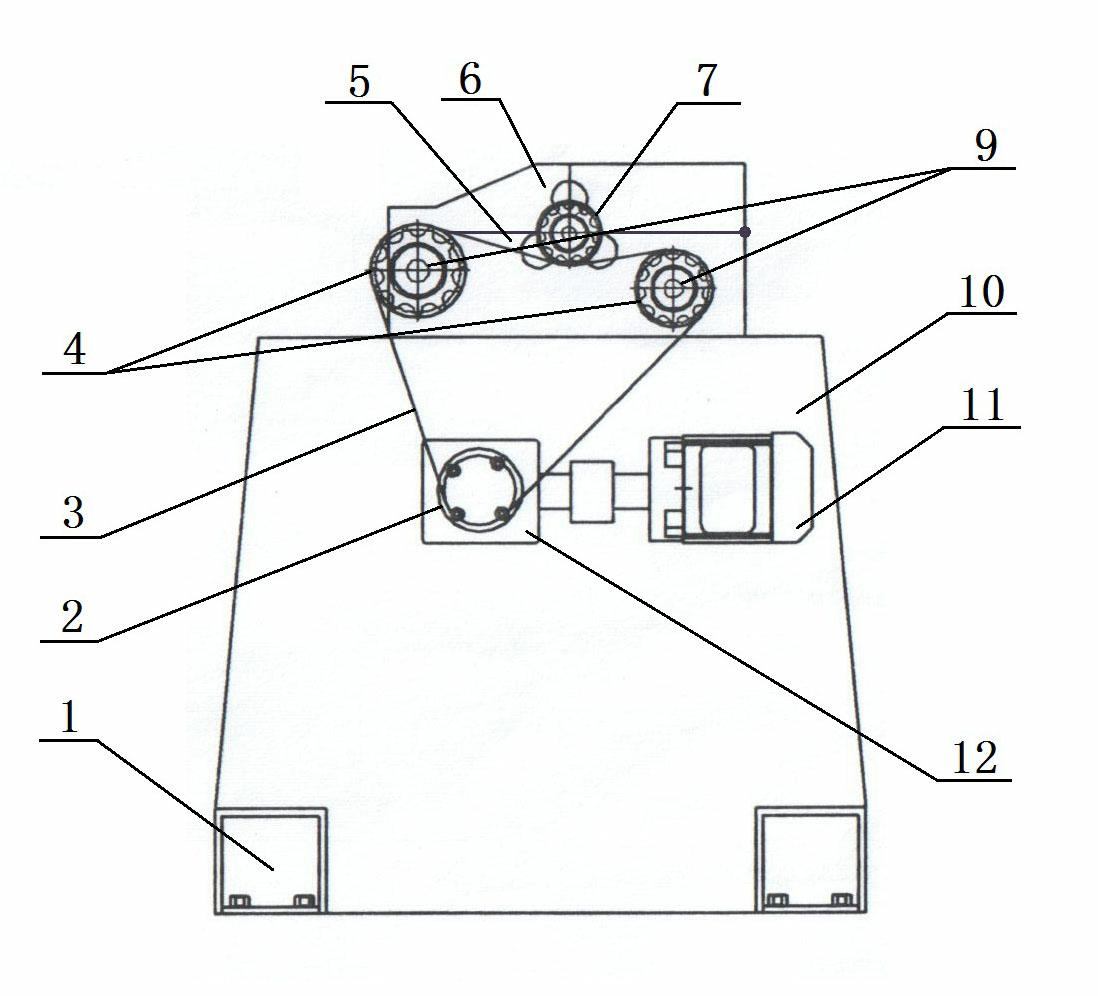

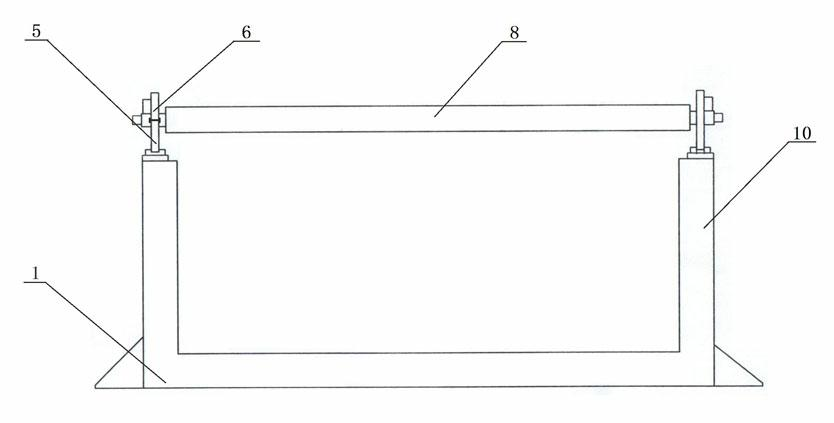

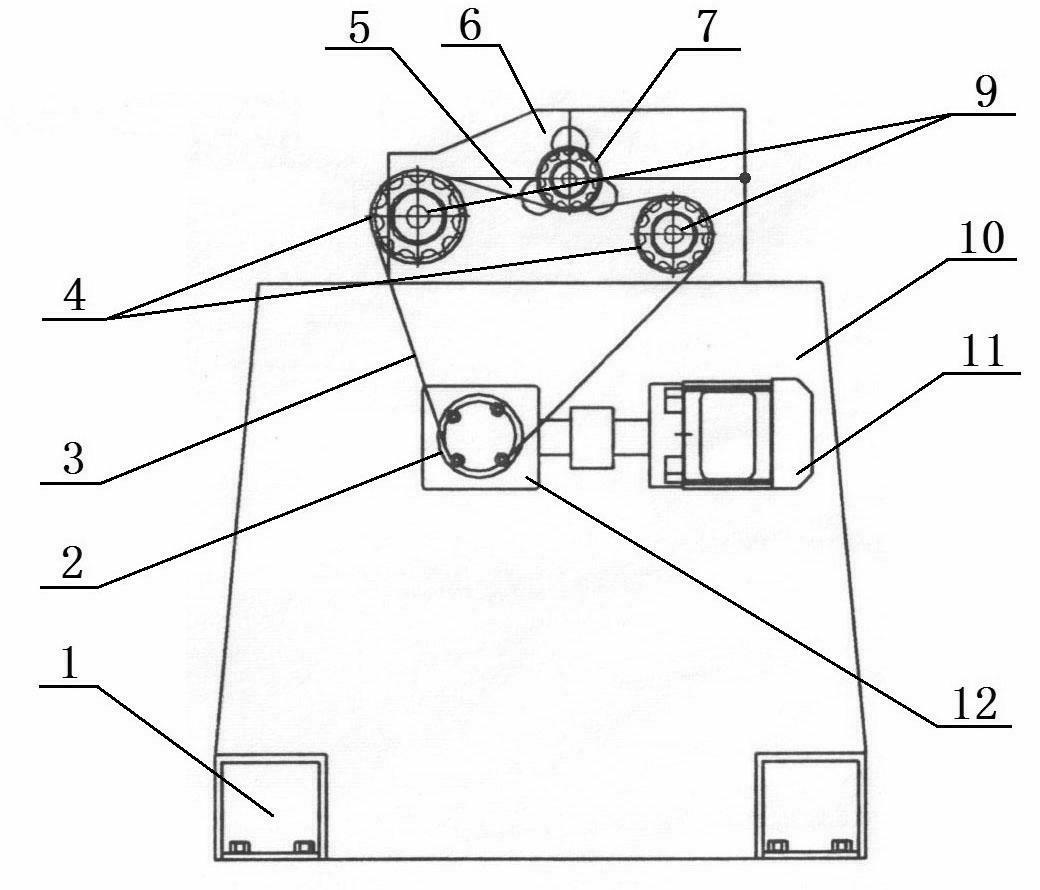

[0011] like figure 1 and figure 2 As shown, the rubber sheet winding machine of the present invention includes a base 1 and a reel 8, and the base 1 is provided with two plate-shaped supports 10, which are parallel between the two plates, and their tops are all provided with shaft seats. , the reel 8 is set between the two shaft seats. Both ends of the reel 8 protrude out of the shaft seat and are fixed with the first sprocket 7 . A power mechanism is fixed on a plate-shaped support 10 below the shaft seat at one end of the reel 8 . Described power mechanism is made up of motor 11 and reducer 12, and the output shaft of motor 11 links to each other with the input shaft of reducer 12, and the output shaft of reducer 12 is equipped with second sprocket 4, and first sprocket 7 and second Chain 3 is wound around sprocket wheel 4. The reel 8 can be driven to rotate through the power mechanism, the chain 3 , the first sprocket 7 and the second sprocket 4 . The shaft seat conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com