Negative pressure modeling and demolding device

A demoulding device and negative pressure molding technology, which is applied to molding machines, casting molding equipment, manufacturing tools, etc., can solve the problems of occupying effective space in the workshop, low equipment utilization rate, and increased production costs, so as to reduce equipment investment and reduce production cost. Production cost, the effect of making full use of the workshop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

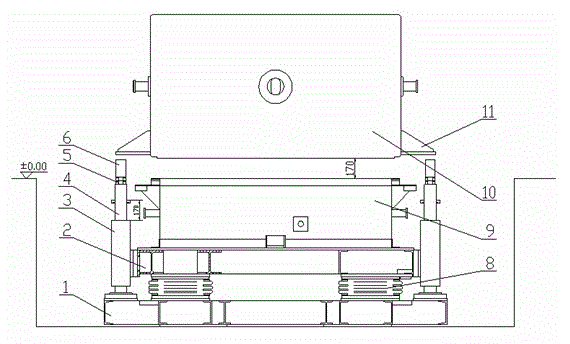

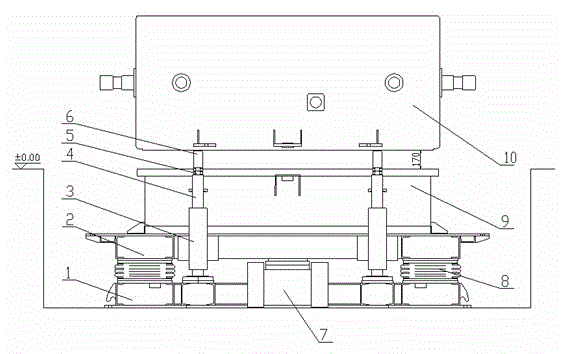

[0014] The negative pressure molding demoulding device of the present invention comprises a base 1, a vibrating table 2 and lifting and damping devices 8 arranged at the four corners of the vibrating table 2, the vibrating table 2 is connected with the base 1 through the lifting and damping devices 8, and the base 1 A sand box pillar 4 is arranged on the four sides of the sand box, and its positioning size should match the support ear 11 of the working sand box. The top of the sand box pillar 4 is provided with an adjusting bolt 5, and the upper end of the adjusting bolt 5 is connected with a pad block 6; guide sleeves 3 are provided on the four sides of the vibration table 2, and the sand box pillar 4 is inserted into the guide sleeve 3 and can slide therein; the bottom of the vibration table 2 is symmetrically provided with a vibration motor 7 , when the vibrating table is lifted and vibrated with the air spring, through the guidance of the guide sleeve, the table will move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com