Ultrasonic nondestructive testing wedge block

A non-destructive testing and ultrasonic technology, which is applied in the direction of material analysis, measuring device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problems of inflexible use, low efficiency, and inability to flexibly change the angle of refraction, etc. The effect of improving convenience and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are given below in conjunction with the accompanying drawings, and the technical solutions of the present invention are described in detail.

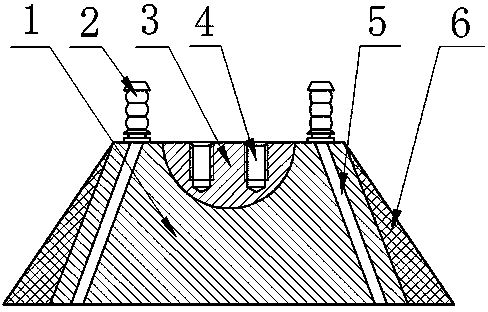

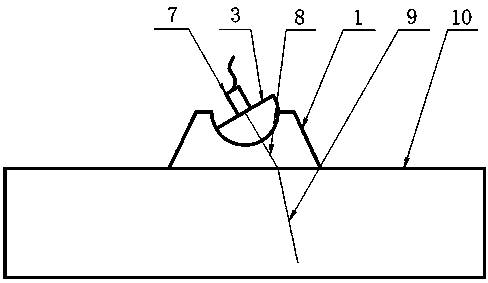

[0016] Such as figure 1 As shown, a wedge for ultrasonic nondestructive testing includes a first-level wedge 3, a second-level wedge 1, a couplant conduit interface 2, an ultrasonic probe interface 4, a couplant through-hole 5 and a sound-absorbing material 6, and the first-level wedge The upper plane of the block 1 is provided with an ultrasonic probe interface 4, and the remaining sides of the primary wedge 3 are flexibly connected to one side of the secondary wedge 1 through a couplant, and the couplant conduit interface 2 is installed on the side of the secondary wedge 1. A couplant through hole 5 is opened on the secondary wedge 1, and an outlet of the couplant through hole 5 is connected to the couplant conduit interface 2, and sound-absorbing materials 6 are provided on the sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com