Mechanical seal device of plant water pump for nuclear power plant

A technology for nuclear power plants and water pumps, which is applied to components, pumps, and pump components of pumping devices used for elastic fluids. It can solve the problems of poor sealing performance compared to mechanical seals, and cannot meet the requirements of plant water pumps, and achieve sealing effects. Good, convenient installation and maintenance, and prevent the leakage of media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

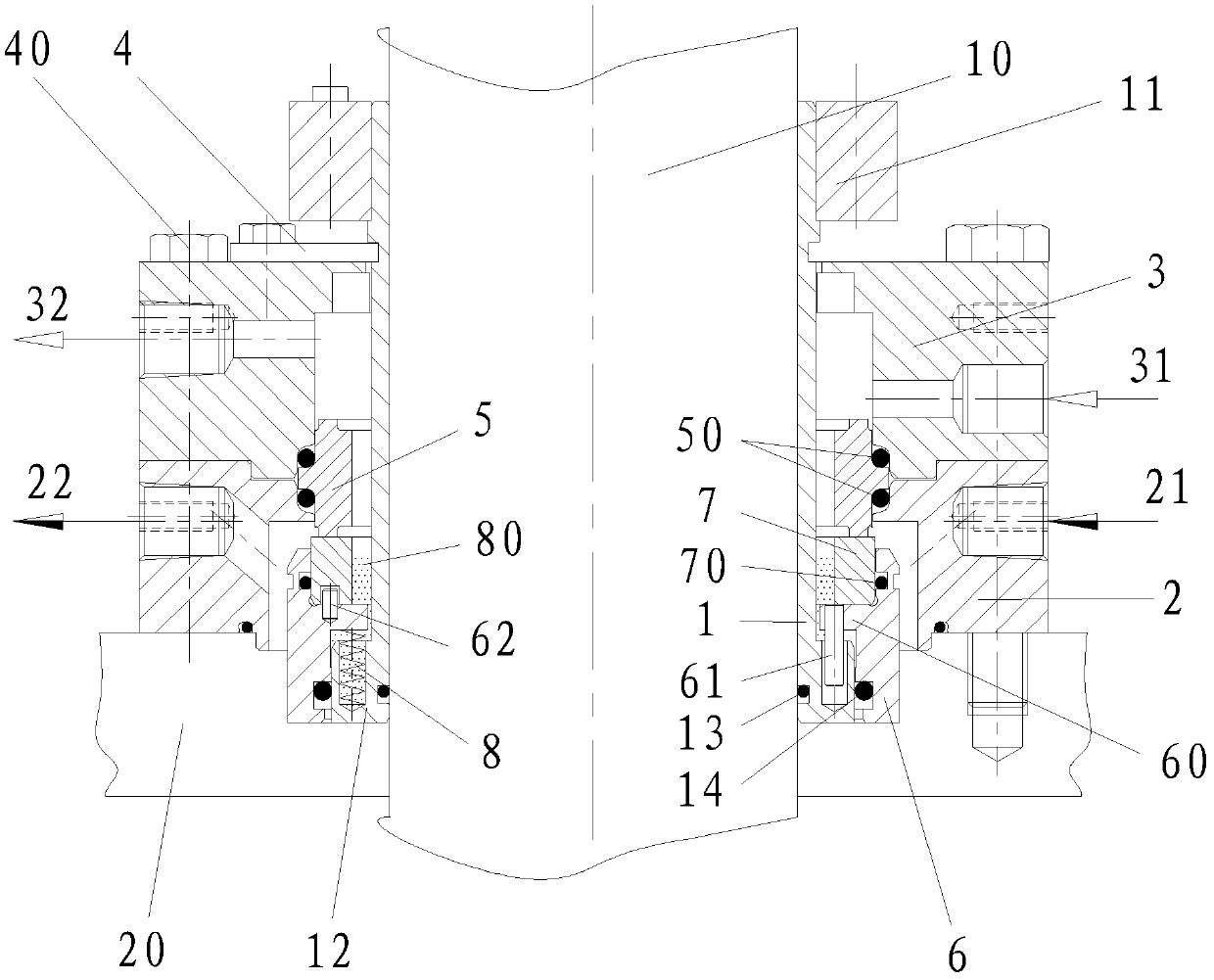

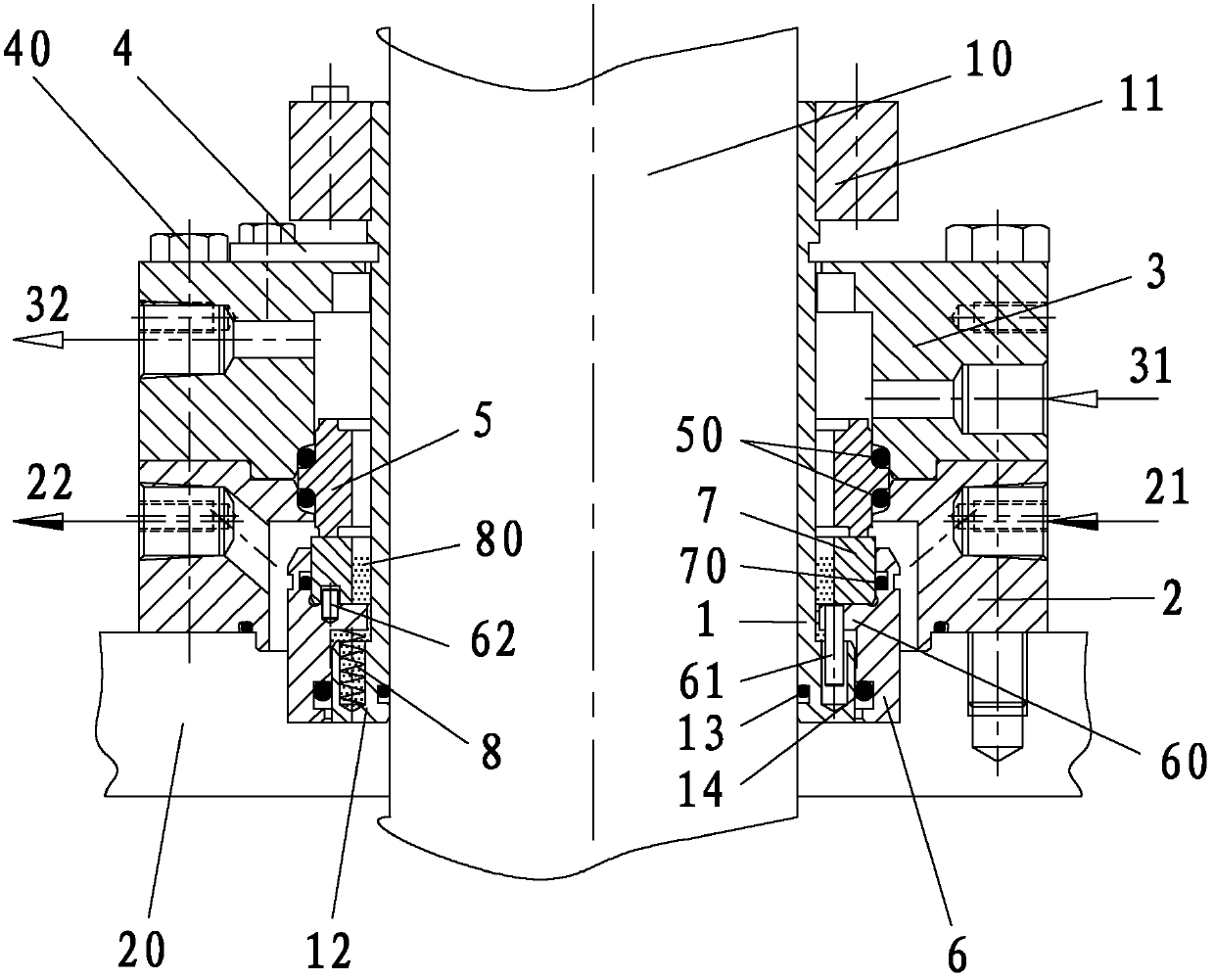

[0023] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

[0024] see figure 1 , a kind of machine seal device for the plant water pump of the nuclear power plant of the present invention comprises machine seal shaft sleeve 1, machine seal chamber 2, machine seal gland 3, assembly plate 4, static ring 5, transmission seat 6, rotating Ring 7 and some springs 8, wherein:

[0025] The mechanical seal shaft sleeve 1 is fixedly sleeved on the pump shaft 10 through the clamping ring 11. The upper part of the outer peripheral surface of the mechanical seal shaft sleeve 1 is provided with a concave ring, and the lower part is provided with an external convex ring 12. The upper part of the external convex ring 12 is The end face is provided with a number of spring holes and a number of positioning pin holes evenly distributed along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com