Oil pumping unit

A technology for pumping units and sucker rods, which is applied in mechanical equipment, machines/engines, liquid variable volume machinery, etc., and can solve the problem of manpower pulling the guide wheel bracket, insufficient reversing stability, and large volume of the rewinding wheel, etc. problem, to achieve the effect of reasonable transmission ratio, increased rigidity, and increased mechanical torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

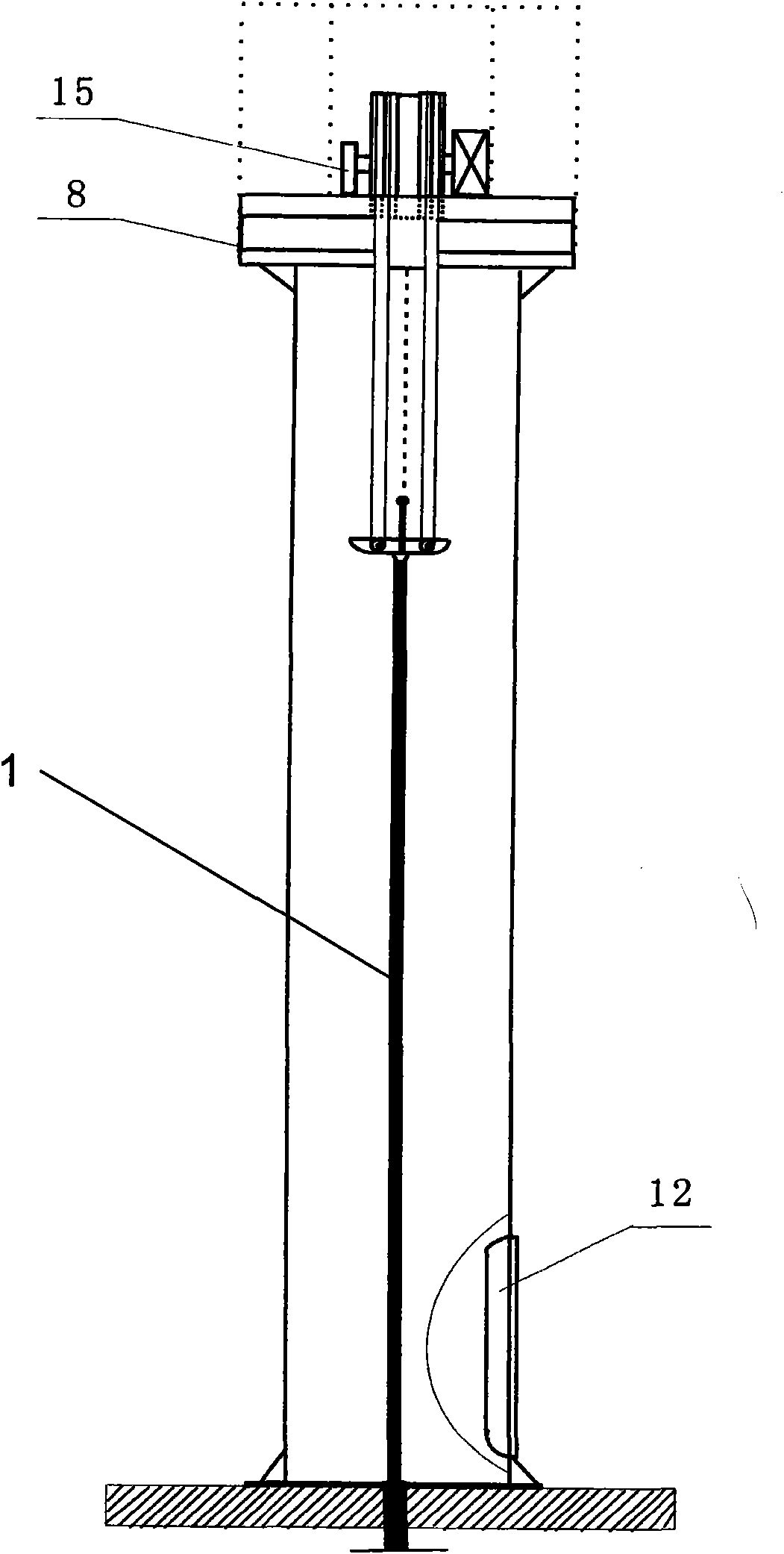

[0057] Figure 1 to Figure 3 A preferred embodiment of the pumping unit of the present invention is shown. see figure 1 , the drum pumping unit in the present invention mainly comprises a vertical main frame 9, a sucker rod 1, a counterweight 11, a platform 8 arranged on the top of the main frame, a motor 27 arranged on the platform 8, multiple The stage reducer 6, the guide wheel 4 and the rewinding wheel 5 cantilevered out of the platform, the motor is connected with the rewinding wheel 5 through the multistage reducer 6 to drive the rewinding wheel. In this embodiment, the main frame 9 has a vertical cavity and a door 14, the control cabinet 12 for controlling the motor is arranged in the vertical cavity, and the counterweight 11 and the counterweight traction rope 16 extend into the vertical cavity indoor. Those skilled in the art should understand that the height of the vertical main frame 9 depends on the length of the stroke when pumping oil. The thickness of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com