Tool and method for manufacturing foot mould

A technology for making tools and molds, which is applied in the field of making tools, can solve problems such as cumbersome use methods, complicated connection relations of foot shape measuring devices, and easy deviation of measurement data, etc., and achieves simple measurement methods, high dimensional stability, and simple assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, a kind of foot model making tool and its method provided by the present invention will be further explained.

[0030] The structure of described foot model making tool is as follows:

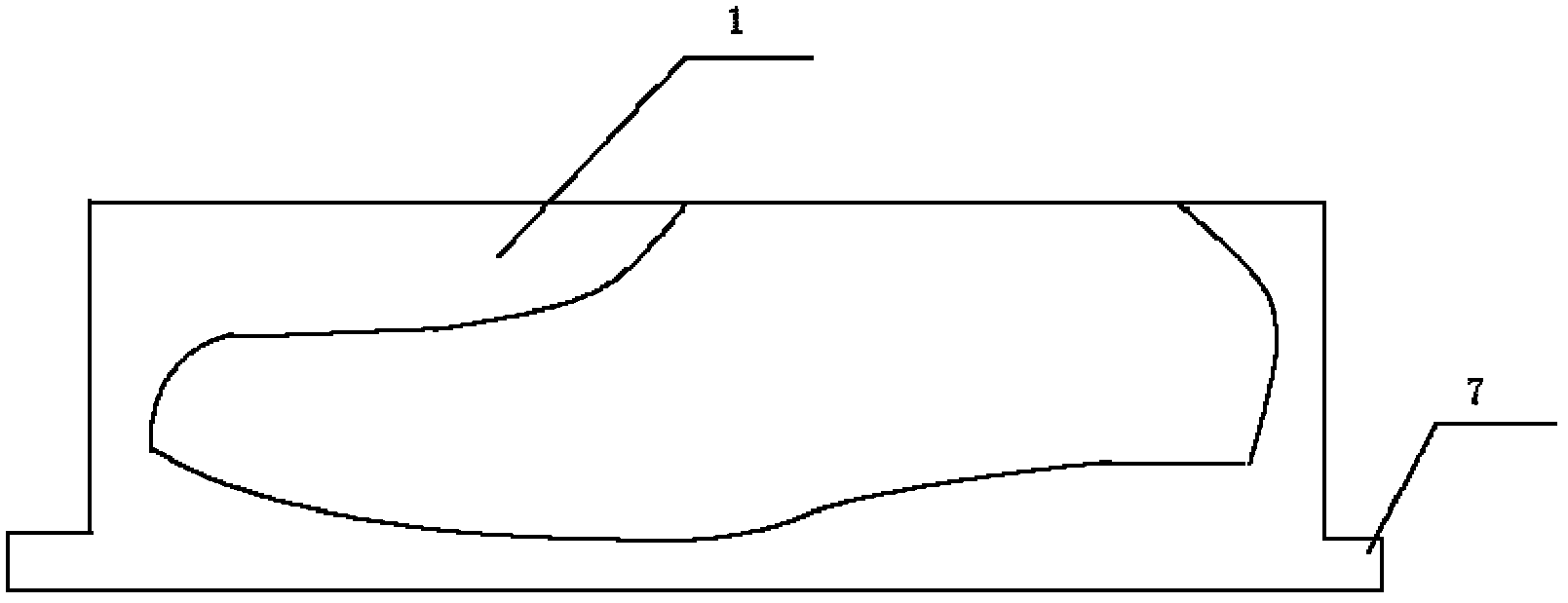

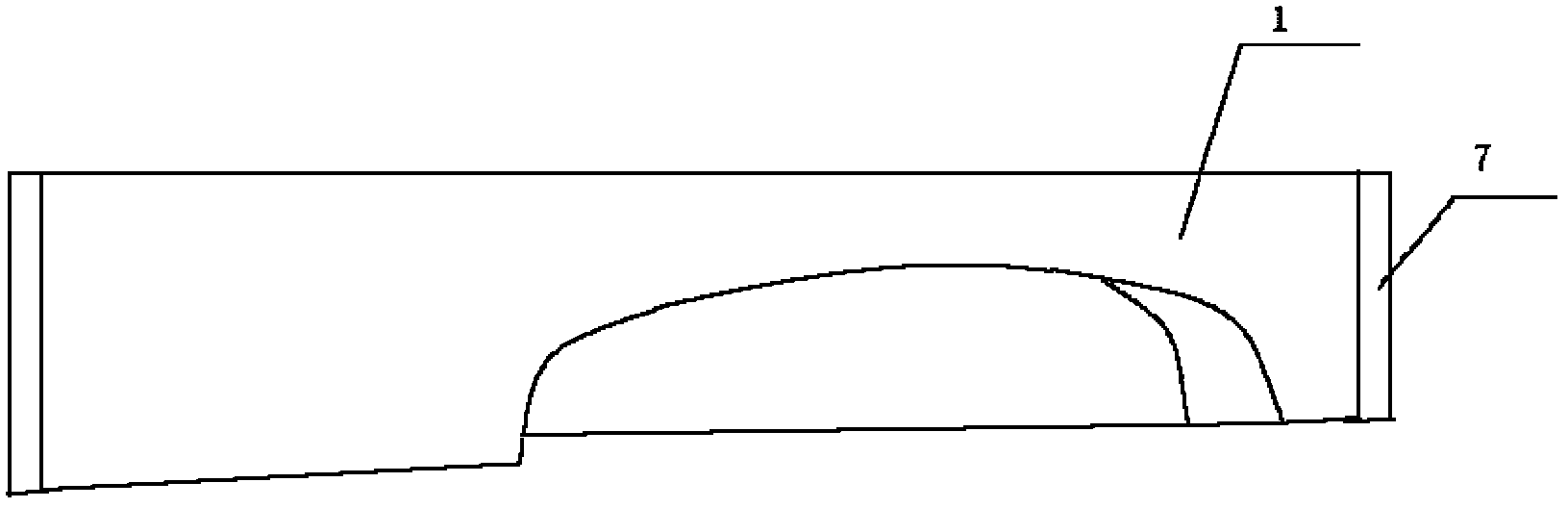

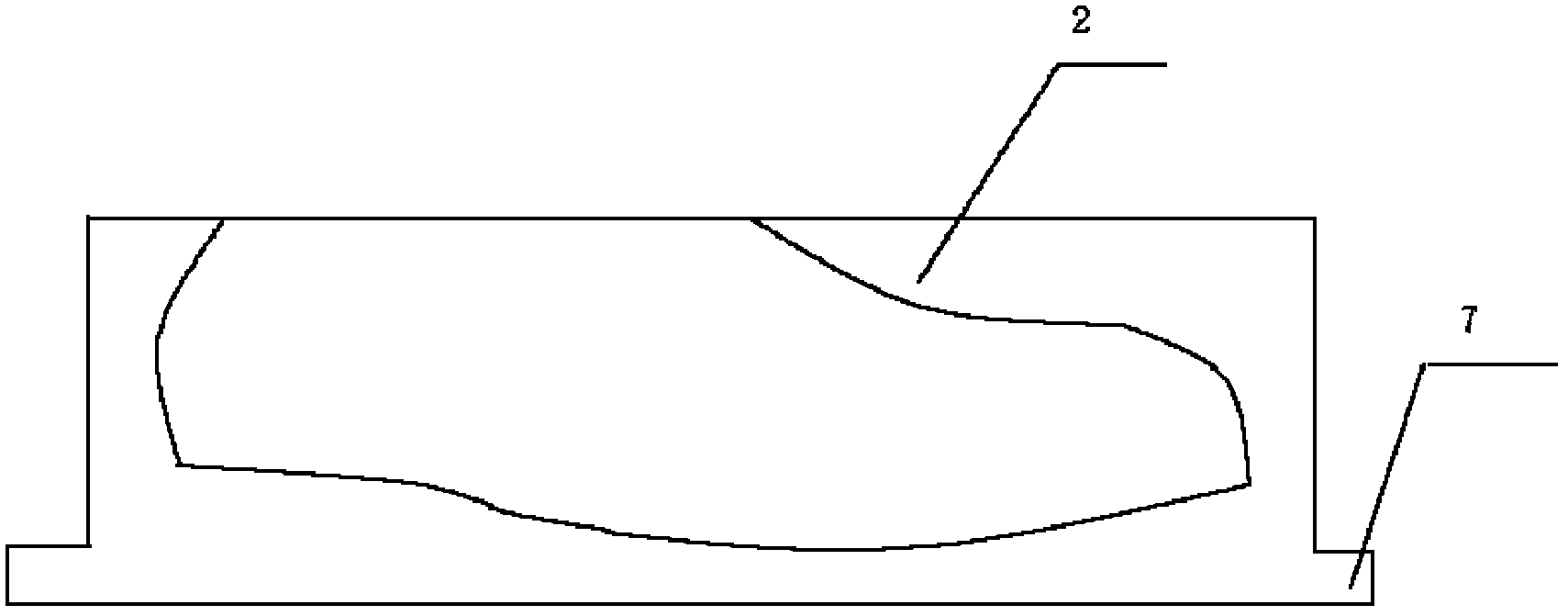

[0031] The tool comprises a first mold 3 (such as Figure 5 shown) and the second mold 4 (as Image 6 shown), the first mold 3 is composed of the first cavity component 1 (such as figure 1 shown) and the second cavity component 2 (as figure 2 As shown), the second mold 4 is composed of a third cavity component 5 (such as image 3 shown) and the fourth cavity component 6 (as Figure 4 shown) splicing composition, the shape of the first mold 3 and the second mold 4 is a foot-like shape.

[0032] Among them, such as Figure 1~4 As shown, the side ends of the first cavity component part 1 , the second cavity component part 2 , the third cavity component part 5 and the fourth cavity component part 6 are provided with protrusions 7 . The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com