Circumferential sampling tool having multiple sample cutters

A cutter and tool technology, applied in the field of circumferential sampling tools, can solve the problem of time-consuming acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

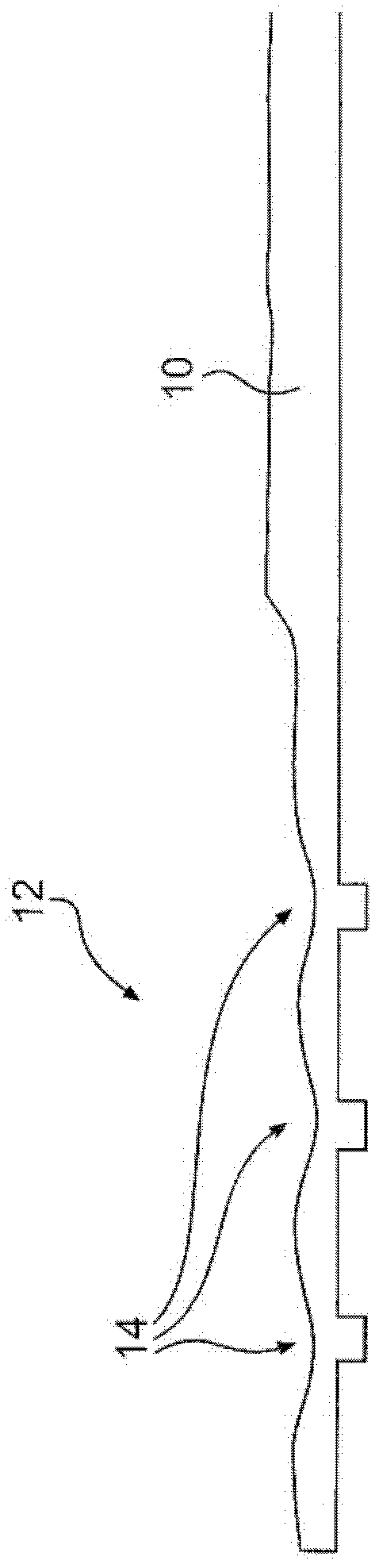

[0048] A circumferential sampling tool of the present invention for obtaining a sample for analysis of deuterium content from a pressure tube of a nuclear reactor will be described. However, it should be understood that the circumferential sampling tool can be used to collect other types of samples from other types of pipes or arcuate surfaces.

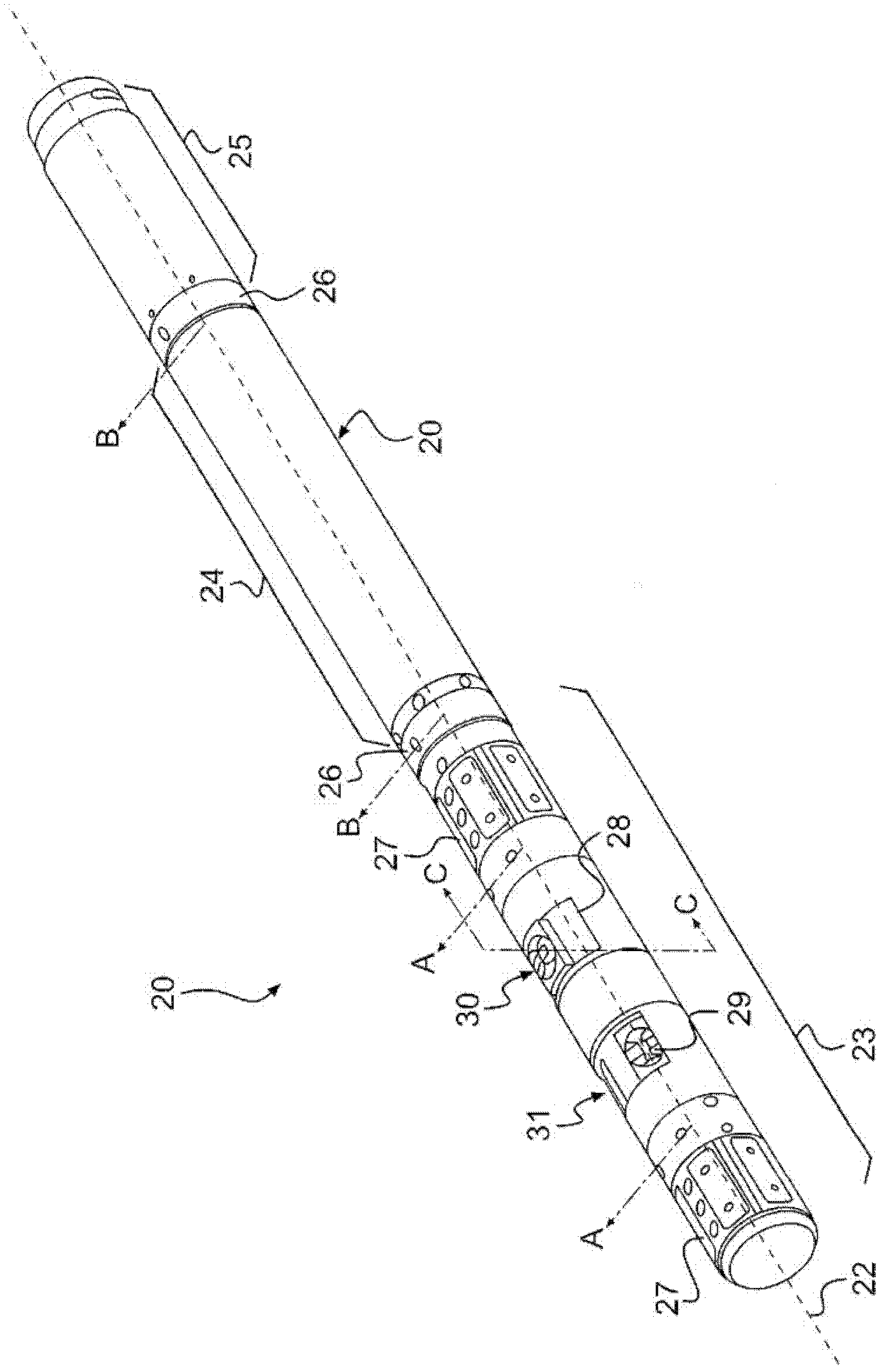

[0049] will refer to figure 2 An embodiment of a circumferential sampling tool 20 is described. The circumferential sampling tool 20 has a cylindrical body 21 with a central axis 22 . The circumferential sampling tool 20 has three main parts: a carriage unit 23 , a drive unit 24 and a hydraulic adjustment unit 25 . The bracket unit 23 , the drive unit 24 and the hydraulic adjustment unit 25 are connected by a flexible joint 26 . Fitting 26 allows circumferential sampling tool 20 to pass through pressure pipe bends without restriction. It should be understood that the central axis 22 of the cylinder 21 shown in the figures corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com