Electromechanical integration nutation oscillating tooth transmission device

A movable tooth transmission, electromechanical integration technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of low life of the slewing arm bearing, difficult processing of the inclined shaft section, etc., to achieve compact structure, small footprint, Design novel and unique effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

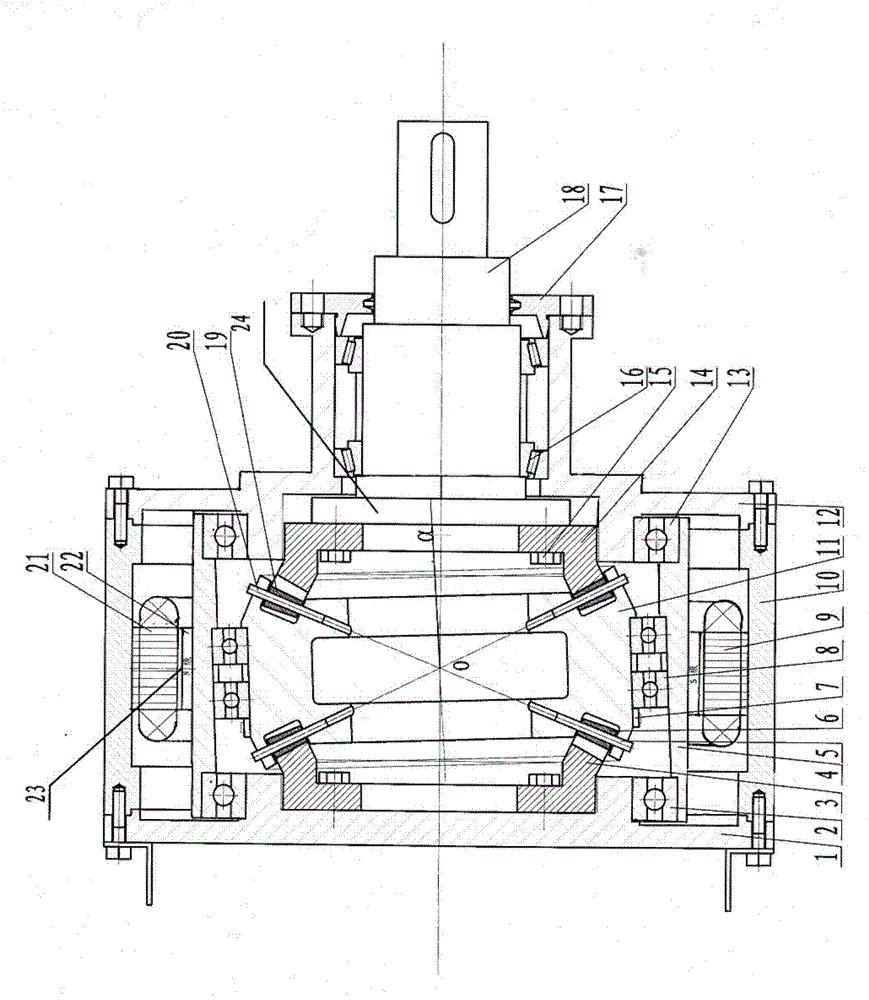

[0012] figure 1 Shown is the specific embodiment of the present invention, and its structure comprises box body 10, it is characterized in that: one end of its box body 10 is installed with fixed plate end cover 1 by screw, is connected by screw in its fixed plate end cover 1 Fixed disk 3; the other end of the box body 10 is equipped with a rotating disk end cover 12 with an outer boss through screws, and the rotating disk end cover 12 is processed with a penetrating concentric shaft consistent with the center of the fixed disk 3 shaft hole. hole, the shaft hole of the rotating disk end cover 12 opposite to the fixed disk 3 is sequentially loaded into the rotating disk 14 and the output shaft 18 of the flange head 24, and the output shaft end of the output shaft 18 passes through the support bearing 16 1. The outer end cover 17 is exposed outside the outer end cover 17; the rotating disk 14 is fixed on the end face of the flange head 24 of the output shaft 18 through bolts 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com