Vertically-loaded coil steel seat frame

A seat frame and coil steel technology, which is applied in the direction of transportation and packaging, railway car body parts, cargo support/fastening parts, etc., can solve the problems of time-consuming reinforcement methods or loading and unloading procedures, lack of versatility, and unsafety, etc., to achieve reduction The effects of loading and unloading time and transportation costs, simple fixing of coils, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

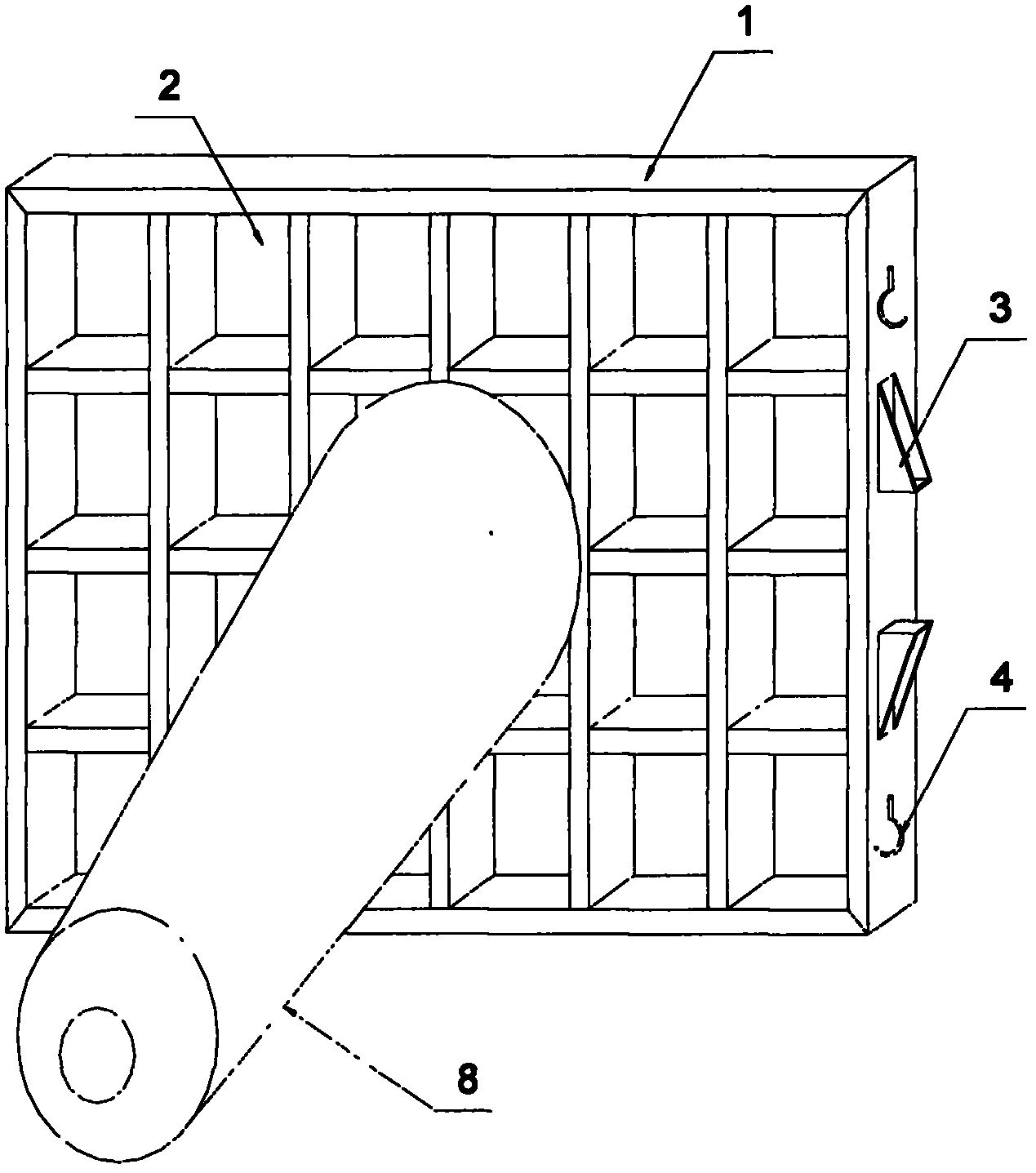

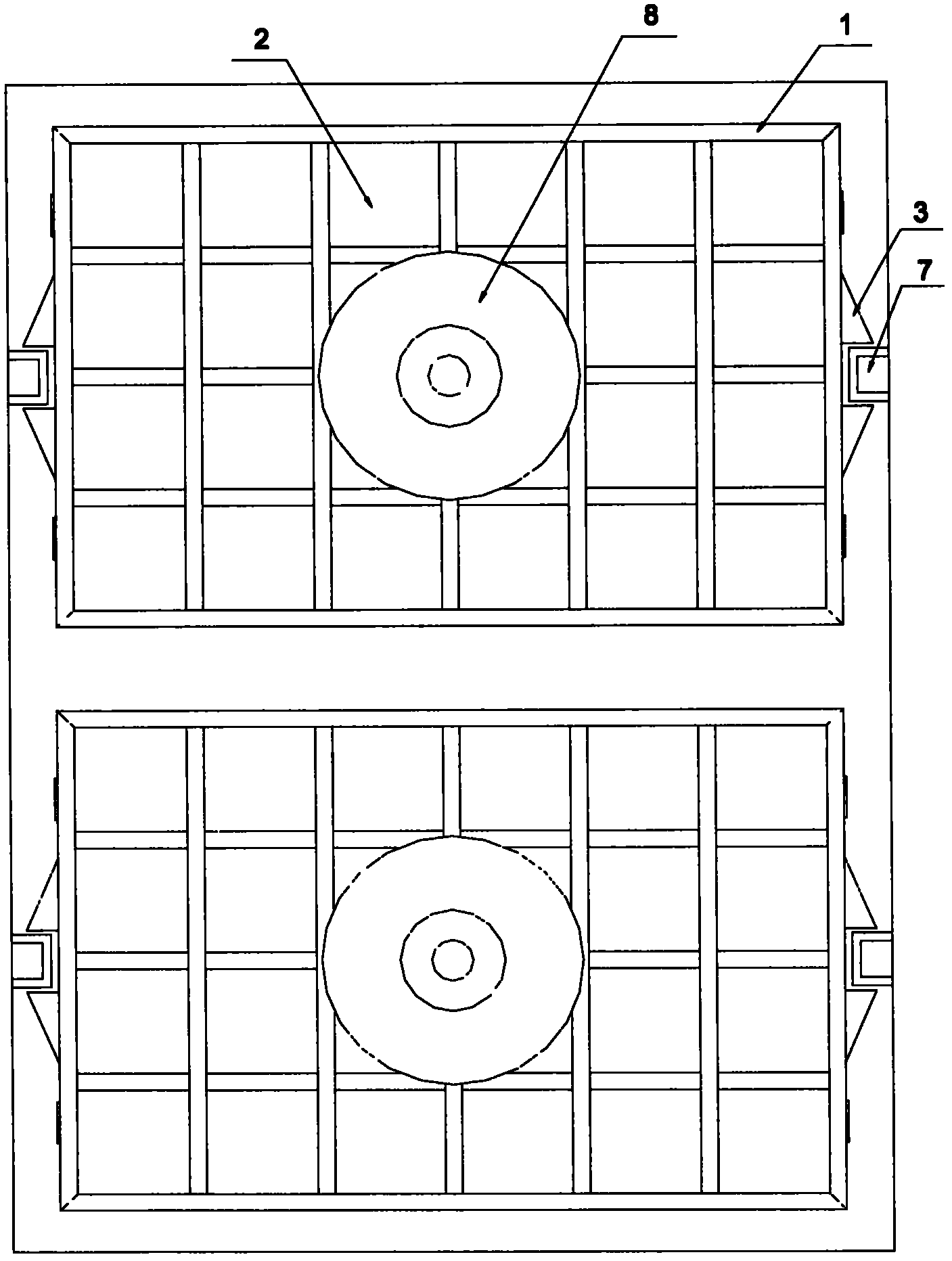

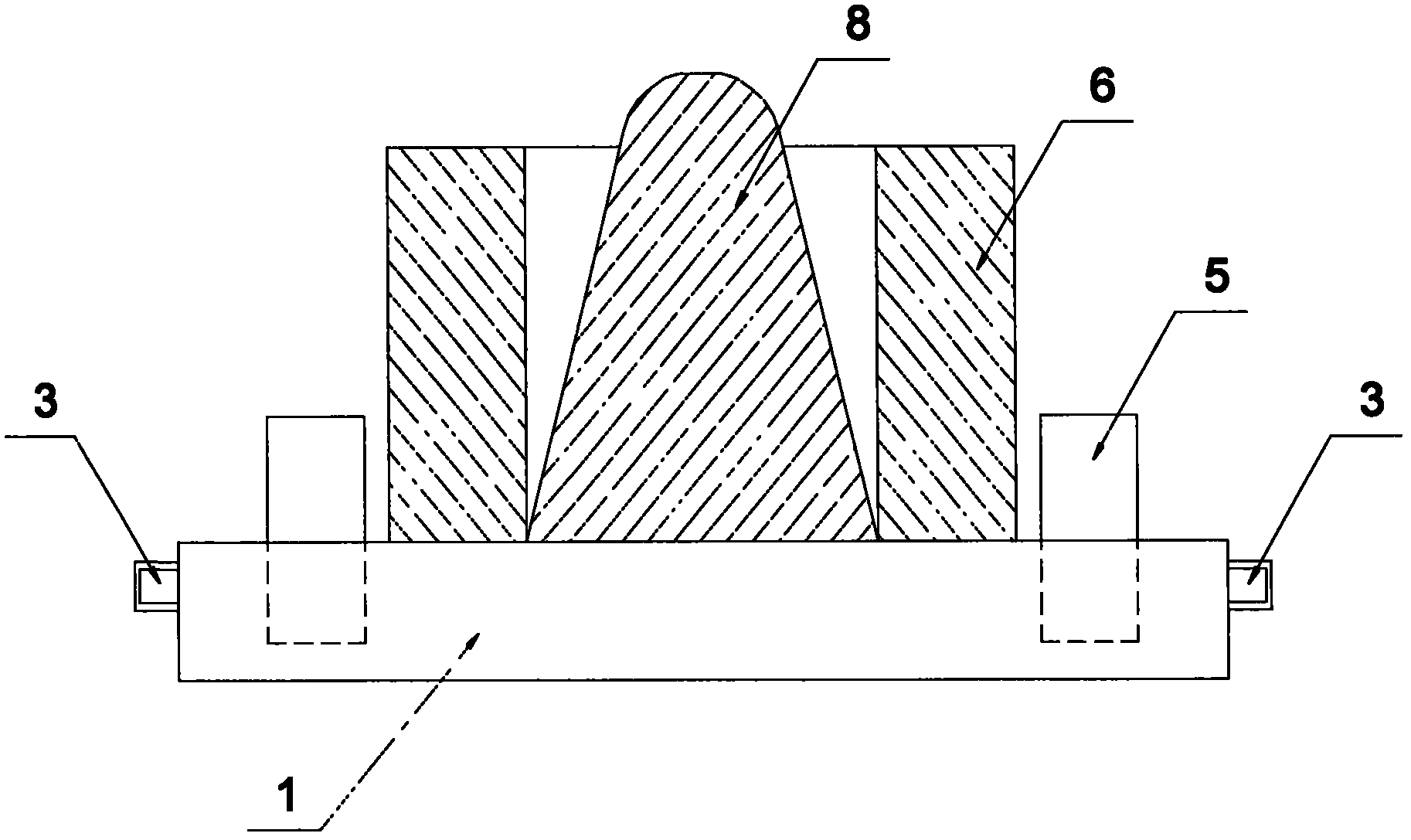

[0016] The coiled steel seat frame 1 of the present invention is made by welding channel steel and square pipes arranged vertically and horizontally. The coiled steel seat frame 1 is provided with a square hole 2, and a baffle pin 5 is inserted in the described square hole 2. The center of the seat frame 1 is welded with a conical fixed cylinder 8, and the two sides of the coiled steel seat frame 1 are provided with triangular baffles 3, and a pair of triangular baffles 3 on each side form a card slot, and a hanger is provided on the outside of the triangular baffle 3. Hook 4, two pairs of hooks 4 are welded on both sides of the coiled steel seat frame 1, the hooks 4 are arranged in the same direction at opposite corners, the hooks 4 on the same side are arranged in opposite directions, and the hooks 4 arranged in the same direction at opposite corners The coiled steel frame 1 can be hoisted and lifted. The coiled steel frame 1 has no front and back sides, and both sides can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com