Novel bionic skeletal muscle based on shape memory alloy driving

A technology of memory alloy wire and skeletal muscle, applied in the field of bionic skeletal muscle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

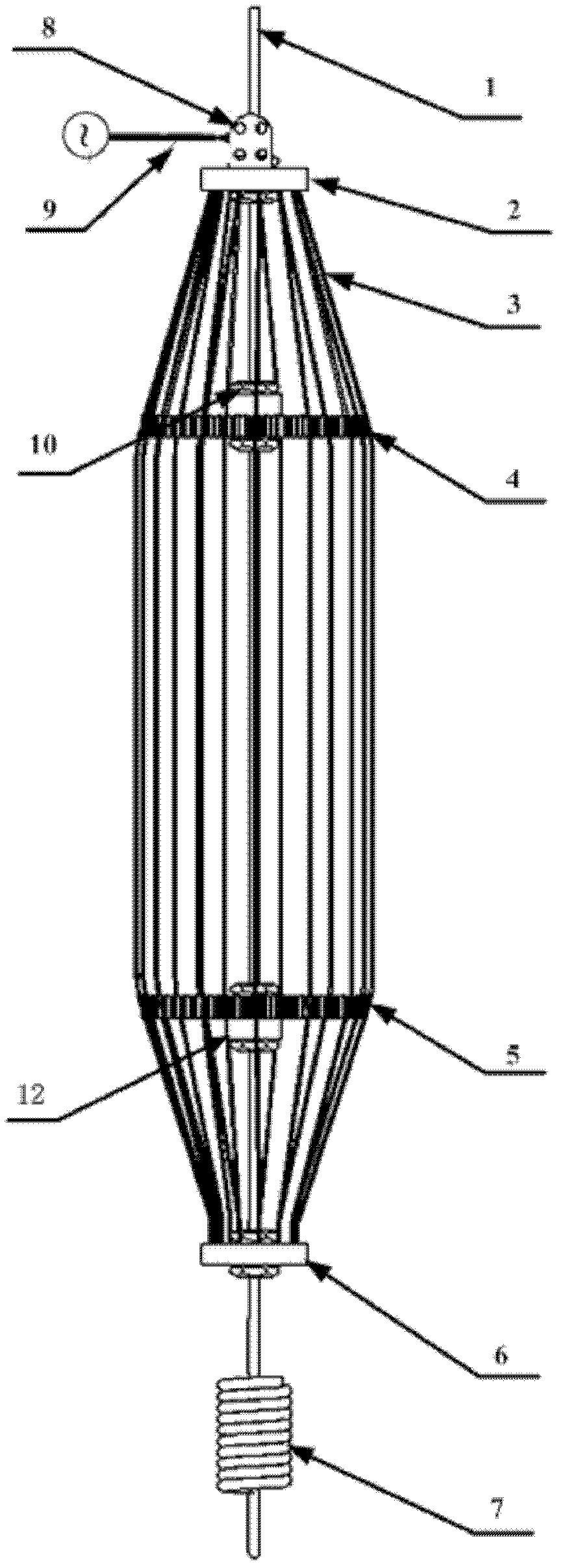

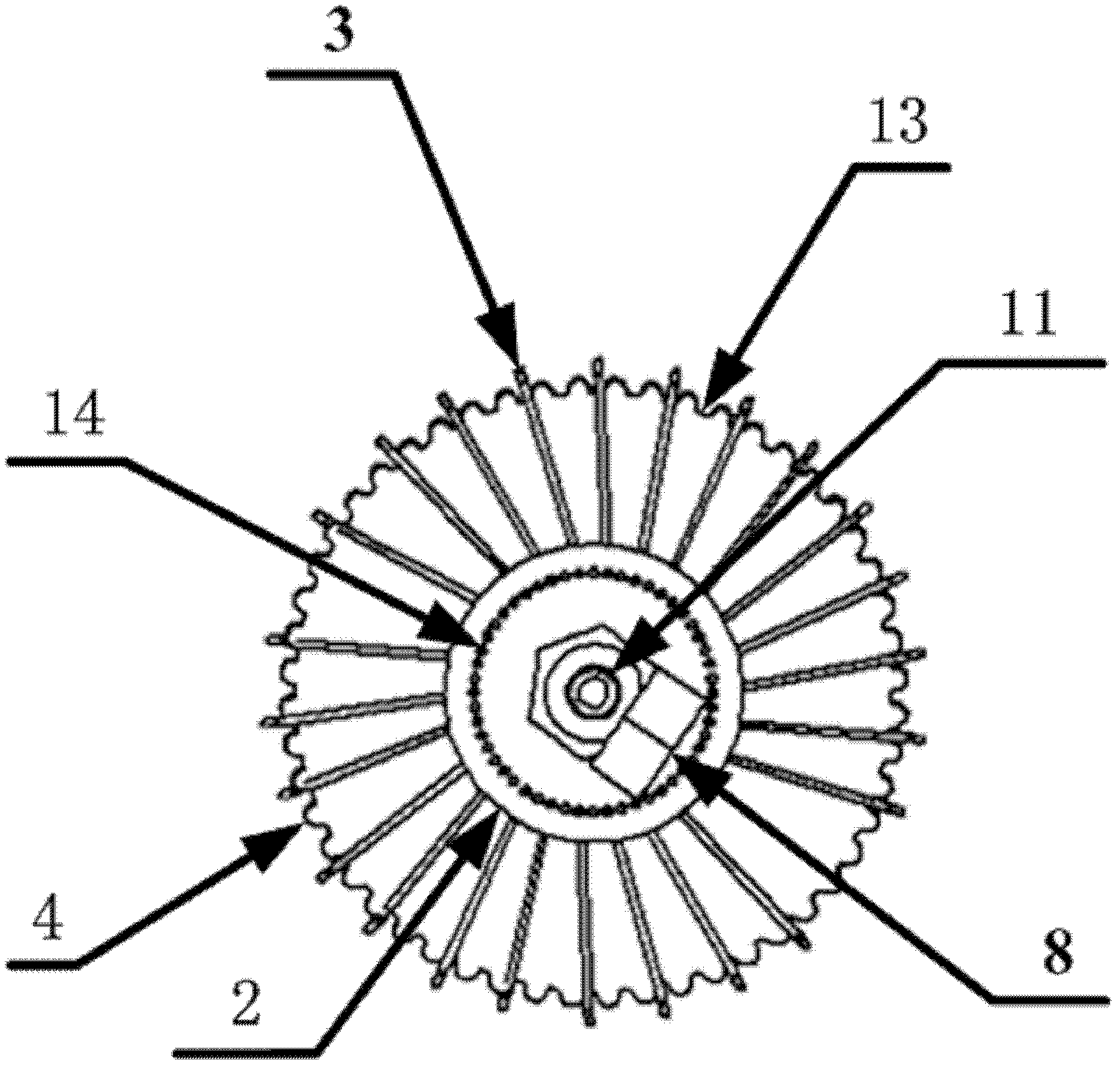

[0019] Such as figure 1 As shown, the bionic skeletal muscle of the present invention includes 24 shape memory alloy wires 3, a first heating circuit board 2, a second heating circuit board 6, two heat dissipation insulating plates 4 and 5, a flexible insulating wire 1 and an energy storage spring 7 . The heat dissipation insulating plates 4, 5 are between the first heating circuit board 2 and the second heating circuit board 6, and the two ends of the shape memory alloy wire 3 are respectively fixed on the first heating circuit board 2 and the second heating circuit board 6, and surround The heat dissipation insulating plates 4 and 5 form the bionic skeletal muscle in a spindle shape. The flexible insulating wire 1 passes longitudinally through the bionic skeletal muscle of the present invention, wherein it passes through the central holes of the two heat dissipation insulating plates 4 and 5 in turn. The flexible insulating wire 1 is fixed on the first heating circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com