Vacuum adsorption device

A technology of vacuum adsorption and vacuum pipeline, which is applied in the field of fixtures, can solve the problems that the circumferential position of the two magnetic steel tiles cannot be guaranteed, the magnetic steel tiles are easy to be damaged, and the quality of the motor is affected, and the operation and use are simple and convenient , comprehensive and reliable detection, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

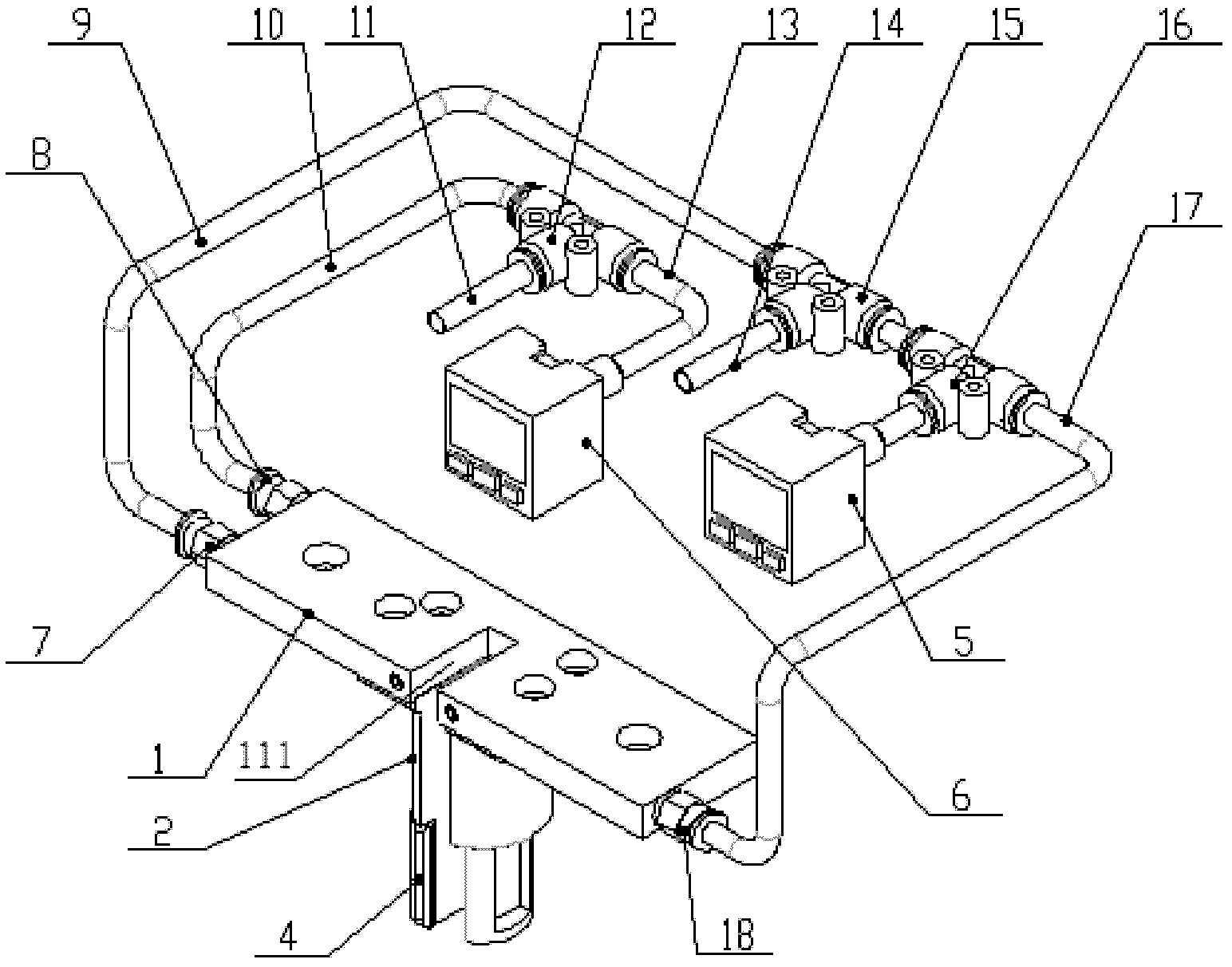

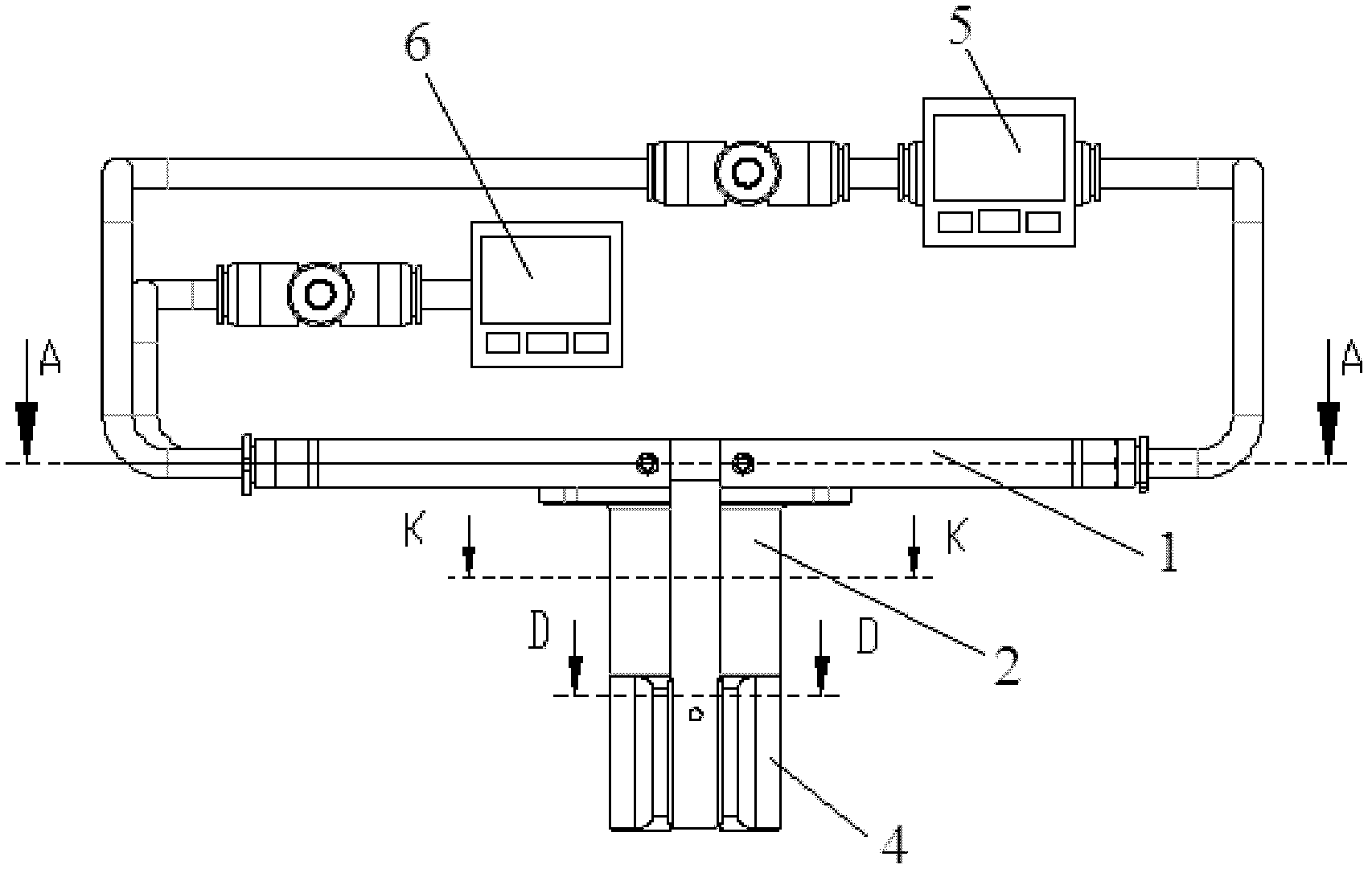

[0031] see Figure 1-Figure 8 , The present invention is a vacuum adsorption device for assembling the magnetic steel tile 4 in the casing 34 of the DC motor. The device includes an installation base plate 1, a placement column 2, a magnetic steel circumferential limit block 3, a right vacuum gauge 5 and a left vacuum gauge 6.

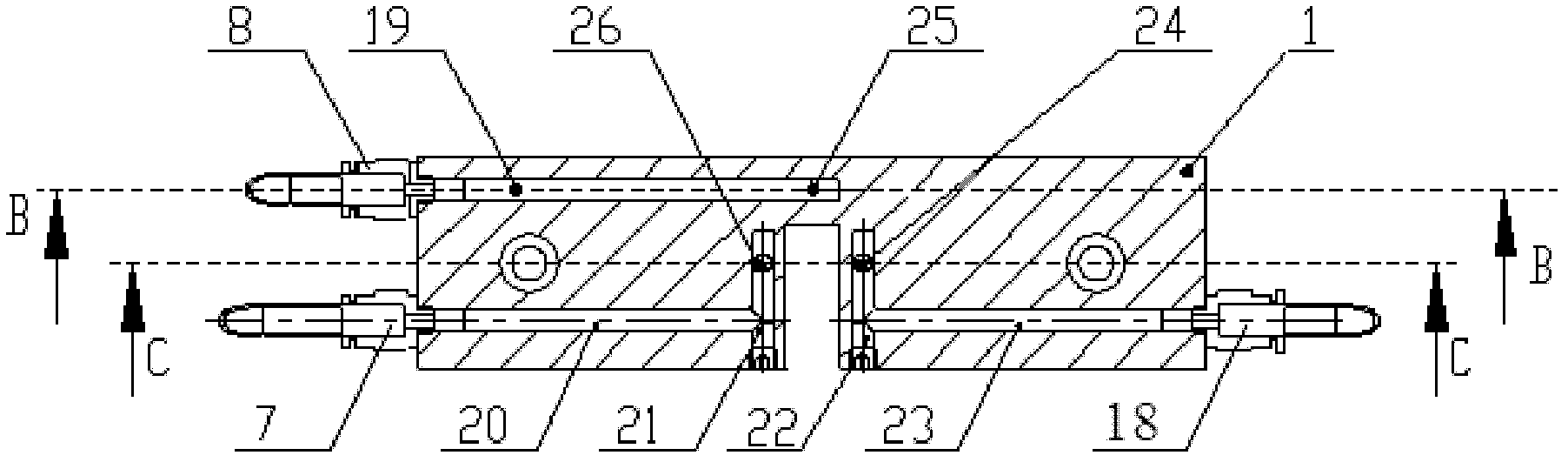

[0032] The middle position of the front side of the installation base plate 1 is provided with a base plate groove 111, and the inside of the installation base plate 1 is provided with first to third transverse pipelines 19, 20, 23, first and second longitudinal pipelines 21, 22 and First to third vertical pipelines 25, 26, 24, wherein:

[0033] The first horizontal pipeline 19 is located near the rear side of the installation base plate 1, and its central section is consistent with the position of the central section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com