Led module manufacturing method and led module

A technology of light-emitting diodes and manufacturing methods, which is applied to semiconductor devices, light sources, and electric light sources of light-emitting elements, and can solve the problems of high production cost, large volume, and light distribution that is easily affected by alignment errors, and achieve cost and volume savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

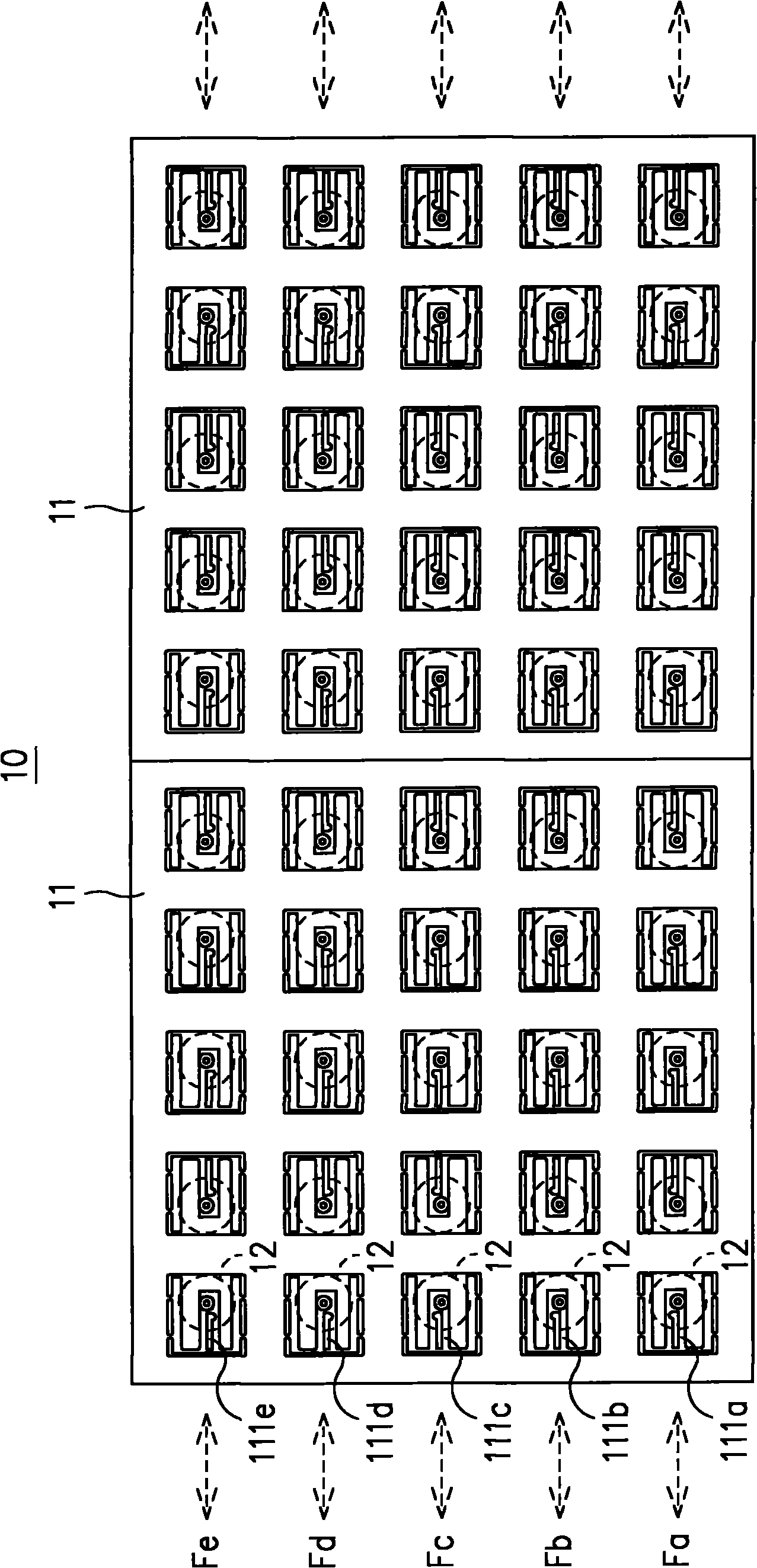

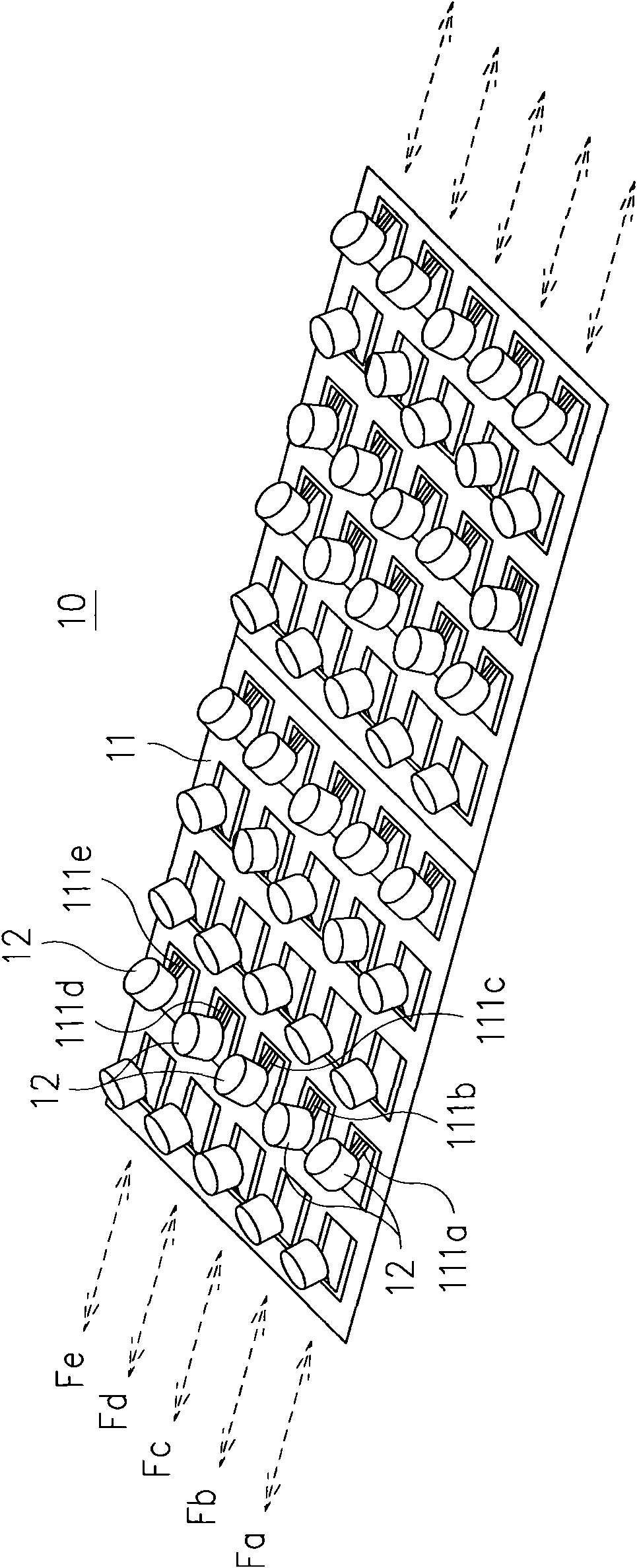

[0058] The technical means and effect that the present invention uses to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only auxiliary descriptions, in order to facilitate the understanding of the technical solutions of the present invention, but the present invention The technical means are not limited to the enumerated drawings.

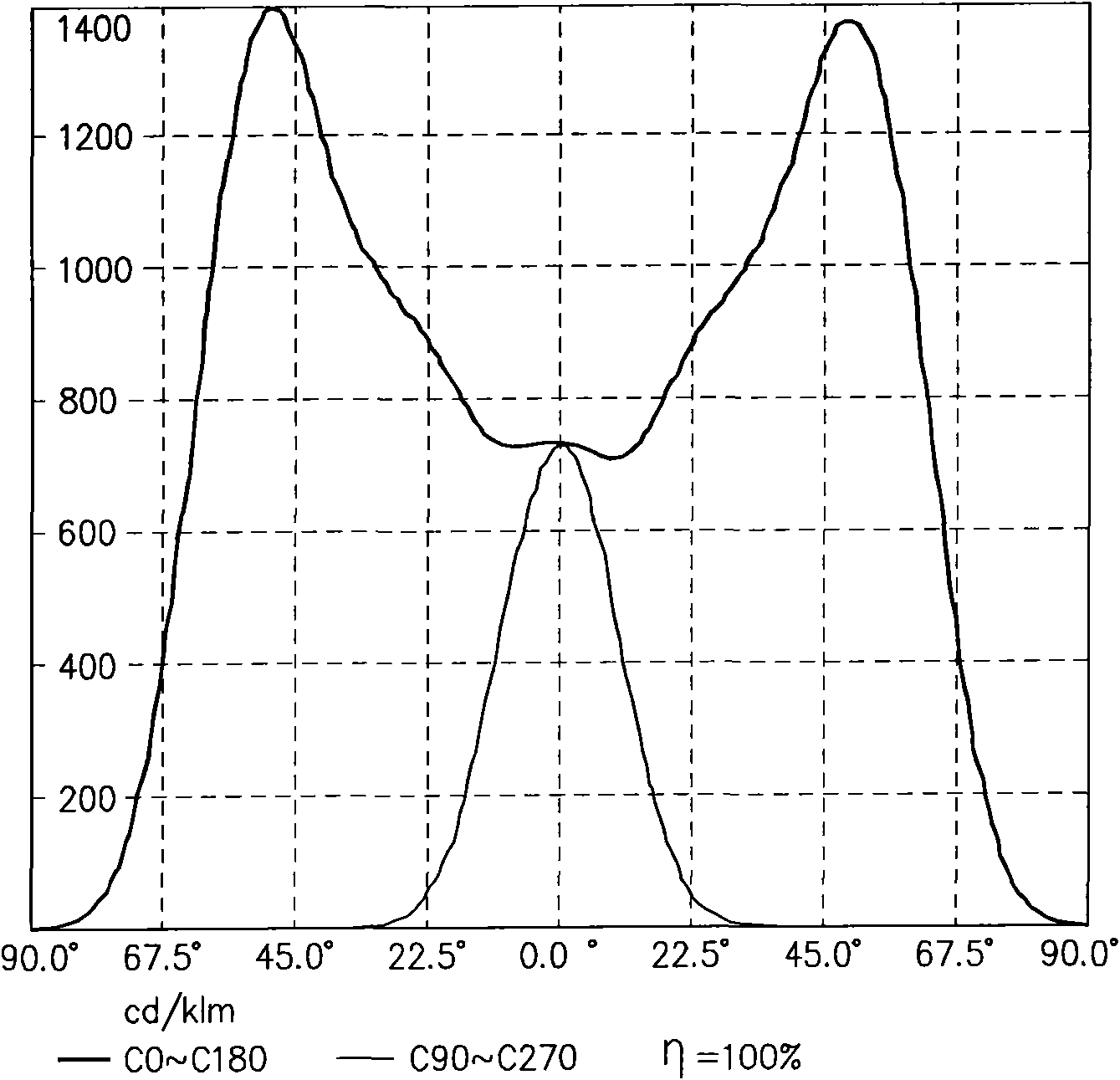

[0059] see Figure 5 to Figure 7 As shown, the manufacturing process of the light-emitting diode module provided by the present invention includes the following steps:

[0060] Step 1: First, according to the required light distribution curve, calculate the light output angle configuration of multiple LEDs and obtain multiple sets of data sets. Each data set corresponds to a light-emitting diode, and each data set includes a light-emitting diode. The rotation angle of the diode on the horizontal plane and the included angle between the light-emitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com