Steel wire hook

A steel wire and head technology, applied in the field of steel wire hooks, can solve the problems of sealing failure of the heat capacity chamber of the heating container, puncturing the operator, and easy damage to the outer fabric of the gasket, so as to prevent the operator from being punctured, solve the sealing failure, Resolving the effect of axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

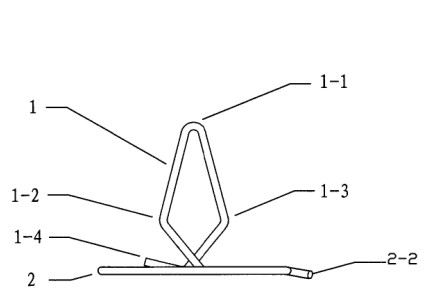

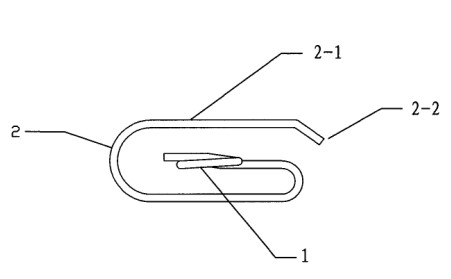

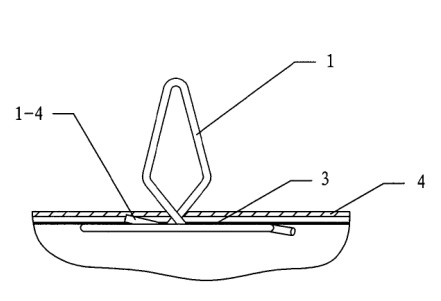

[0016] Such as Figure 1~2 As shown, a wire hook, the hook includes a head 1 and a bottom 2 made of metal wire, the head 1 and the bottom 2 are connected together, the planes where the head 1 and the bottom 2 are located are perpendicular to each other, and the head 1 has a The top 1-1 with a circular arc and the symmetrical left shoulder 1-2 and right shoulder 1-3 formed by the downward extension of the metal wire, the lower end of the head 1 has a short foot 1-4 forming an angle with the bottom 2, and The short legs 1-4 are tilted towards the top 1-1, the bottom 2 is approximately oval, and is formed by winding metal wires in the horizontal direction, the bottom 2 has long legs 2-1 with curved ends, and the ends of the long legs 2-2 are at the same time Bend to the bottom plane of the hook and the plane where the head of the hook is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com