Thermal expansion valve

A technology of thermal expansion valve and valve hole, applied in the field of thermal expansion valve, can solve the problems of unstable system pressure of valve hole, system pressure fluctuation, large flow rate, etc. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

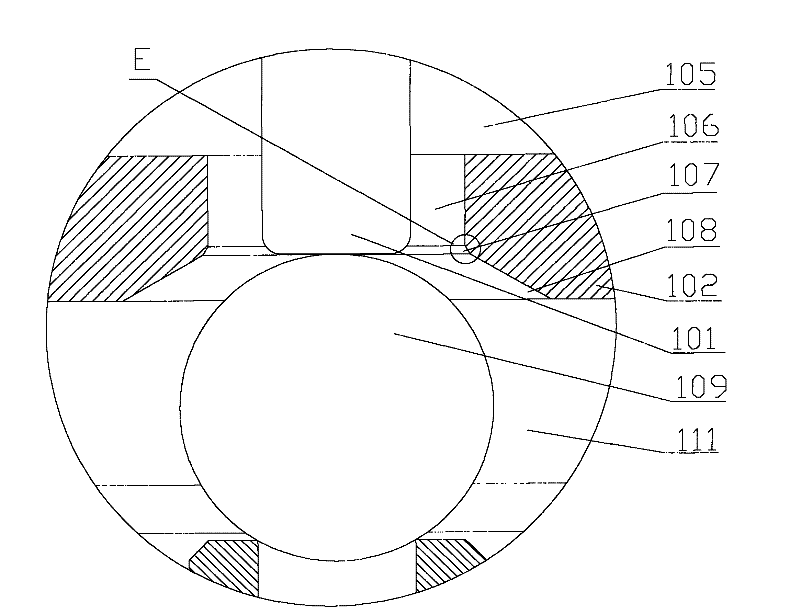

[0028] Such as figure 1 As shown, the thermal expansion valve of the present invention includes a valve body 102, and the valve body 102 includes an inlet port 104 for introducing high-pressure refrigerant, a valve chamber 111 communicating with the inlet port 104, a valve hole arranged in the valve chamber 111, and An outlet port 105 through which refrigerant expanded due to the opening and closing of the valve hole is led to the outside, and a return passage 103 through which refrigerant flows through the evaporator and returns to the compressor.

[0029] Such as figure 1 The thermal expansion valve shown further includes a valve stem 101 slidably installed in the valve body 102 through the return channel 103 and the valve hole, one end of which is connected to the valve core 109, and the other end is pushed by the thermal element 100 to control the opening of the valve hole .

[0030] The specific shape of the spool can be arbitrarily designed according to actual use requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com