Expansion joint of pipeline compensator, manufacturing method thereof and pipeline compensator

A technology for pipeline compensators and manufacturing methods, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, pipe components, etc., which can solve leakage, poor reliability of pipeline compensators, and increase equipment maintenance and maintenance costs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

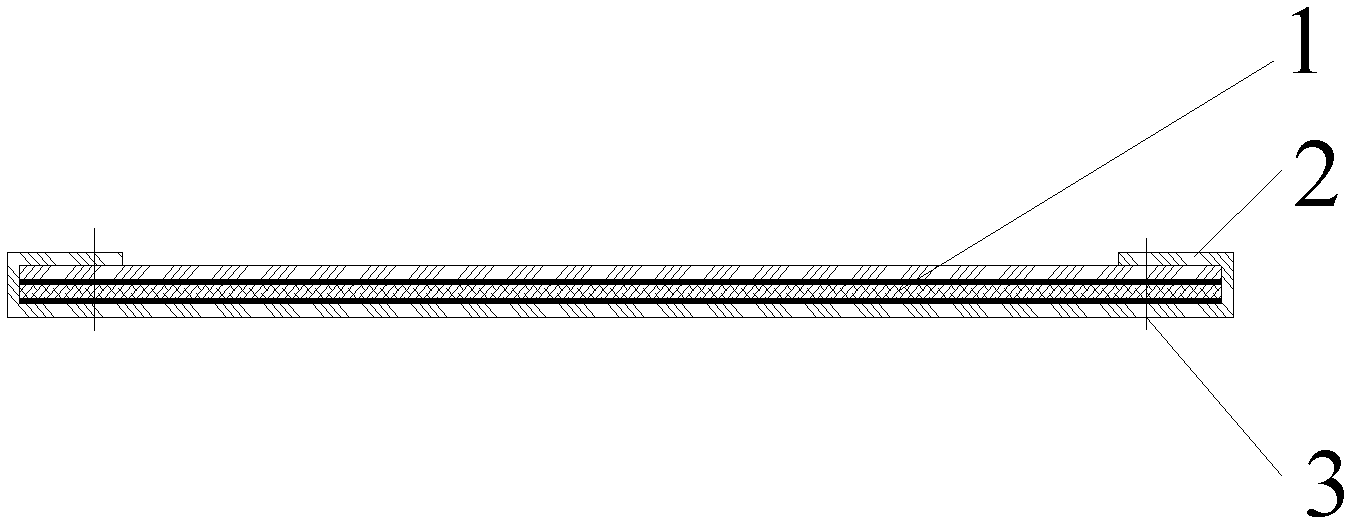

[0034] like figure 2 As shown, the expansion joint 10 of the pipeline compensator according to the embodiment of the present invention, wherein the expansion joint 10 includes a plurality of material layers 1 made of a flexible material, and the plurality of material layers 1 are superimposed on each other to be integrated and can be arbitrarily Adjacent material layers are bonded together without gaps.

[0035] The multiple material layers 1 of the expansion joint 10 can bond adjacent material layers to each other by means of bonding, vulcanization or hot pressing, so that there is no gap between the material layers and the bonding is tight. A plurality of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com