Low-thermal-shrinkage low-smoke halogen-free flame retardant sheath material for optical cable and preparation method

A low-smoke flame-retardant and sheath material technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of optical cable cracking, detachment of optical fiber and sheath at the interface, and attenuation of optical cable transmission signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

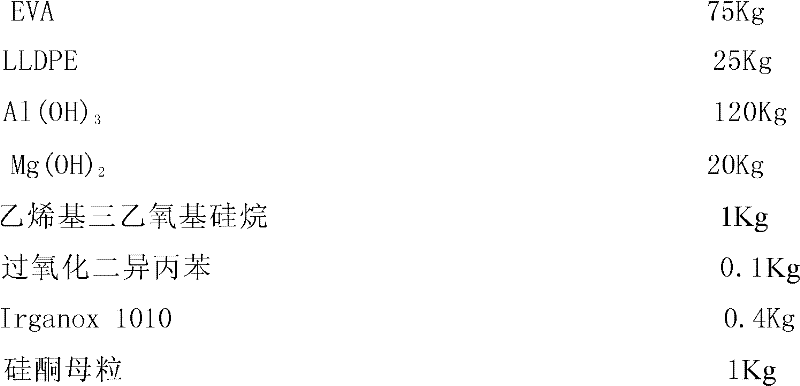

[0066] Each component name and each component parts by weight are as follows:

[0067]

[0068] The preparation method of the above-mentioned invention comprises the following processing steps:

[0069] Mix aluminum hydroxide, magnesium hydroxide, vinyl triethoxysilane, dicumyl peroxide, Irganox 1010, and silicone masterbatch in proportion until the temperature reaches 70°C±5°C, place the material out, and mix with other components Extrude and granulate according to the ratio.

[0070] The product in Example 1 is subjected to a performance detection test, and each performance value is as shown in the performance example.

Embodiment 2

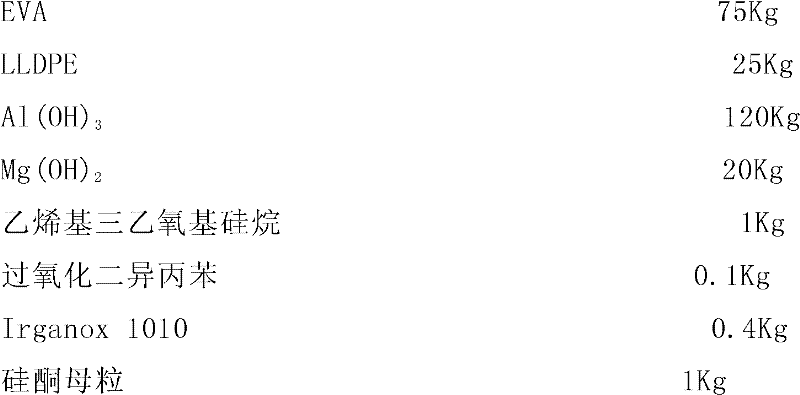

[0072] Each component name and each component parts by weight are as follows:

[0073]

[0074] The preparation method of the above cable material is similar to that of Example 1.

[0075] The product in Example 2 is subjected to a performance detection test, and each performance value is as shown in the performance example.

Embodiment 3

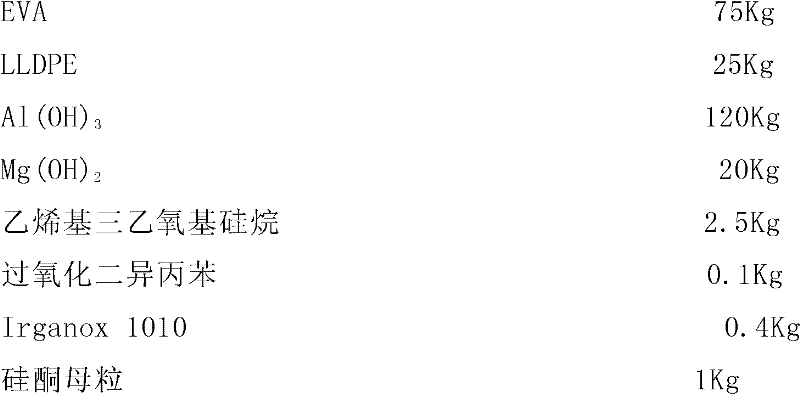

[0077] Each component name and each component parts by weight are as follows:

[0078]

[0079] The preparation method of the above cable material is similar to that of Example 1.

[0080] The product in Example 3 is subjected to a performance detection test, and each performance value is as shown in the performance example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com