Safety injector needle seat structure

A safety syringe and needle holder technology, applied in the field of medical devices, can solve the problems of inability to realize automatic rear assembly of parts, inability to complete parts demoulding at one time, increase product manufacturing cost, etc., achieve a significant clamping effect, and improve market competitiveness. , the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below with reference to accompanying drawing, the present invention is further described

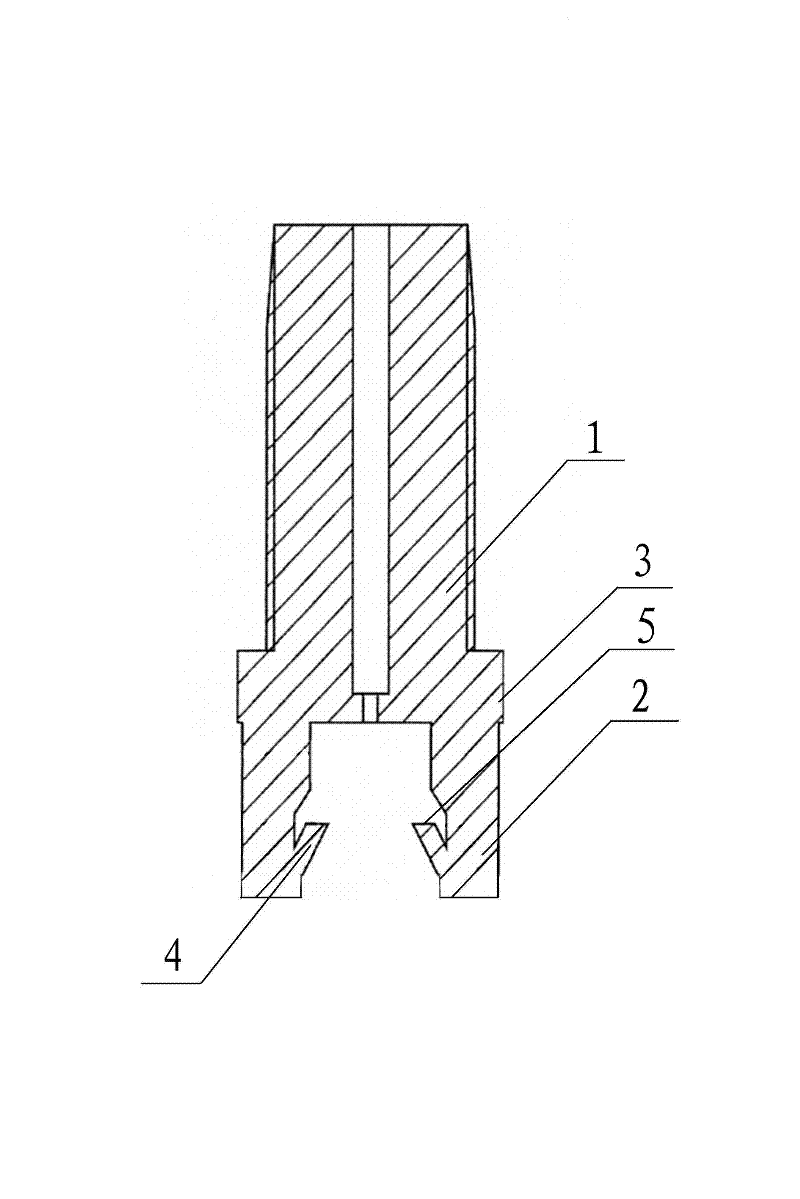

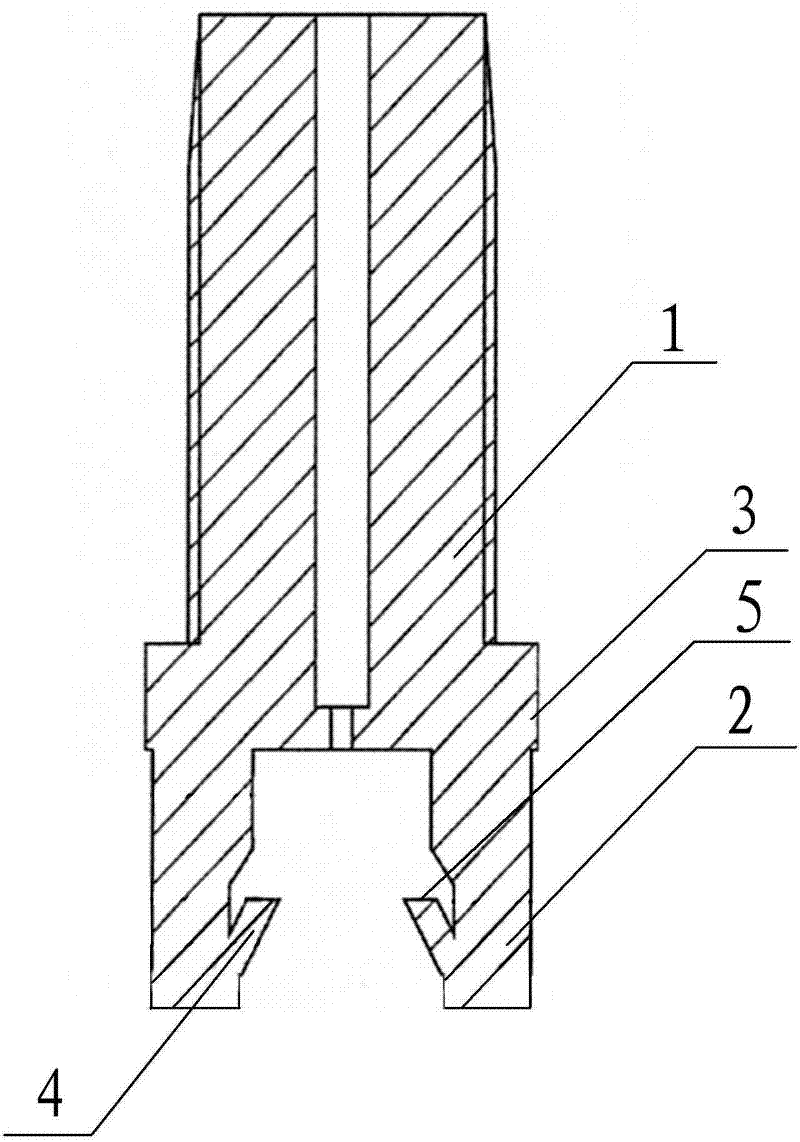

[0012] The present invention is a safety syringe needle seat structure, which includes a needle seat body, characterized in that: the needle seat body is composed of an upper needle tube base 1 and a lower locking base 2, and the upper needle tube base 1 and the lower locking base The junction of the base 2 forms an annular limiting rib 3, the height of the annular limiting rib 3 is 0.3mm-2.3mm, the outer diameter of the annular limiting rib 3 is 2mm-7mm, and the lower locking base 2 The inner cavity is hollow, and the inner wall of the hollow cavity is provided with at least two symmetrically distributed elastic fins 4. The end faces of the elastic fins 4 form a plane 5, and the distance between the plane 5 and the annular limiting rib 3 is 1mm -5mm.

[0013] During specific implementation, 2 is cylindrical, and its outer diameter is 1.8mm-6.8mm.

[0014] In a specific implemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com