Rotary drying furnace

A drying furnace, rotary technology, applied in the direction of progressive dryer, hearth furnace, drying solid materials, etc., can solve the problems affecting production efficiency, overheating temperature, affecting product quality, etc., to improve the utilization rate of internal space, Average heating effect, effect of alleviating uneven internal temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

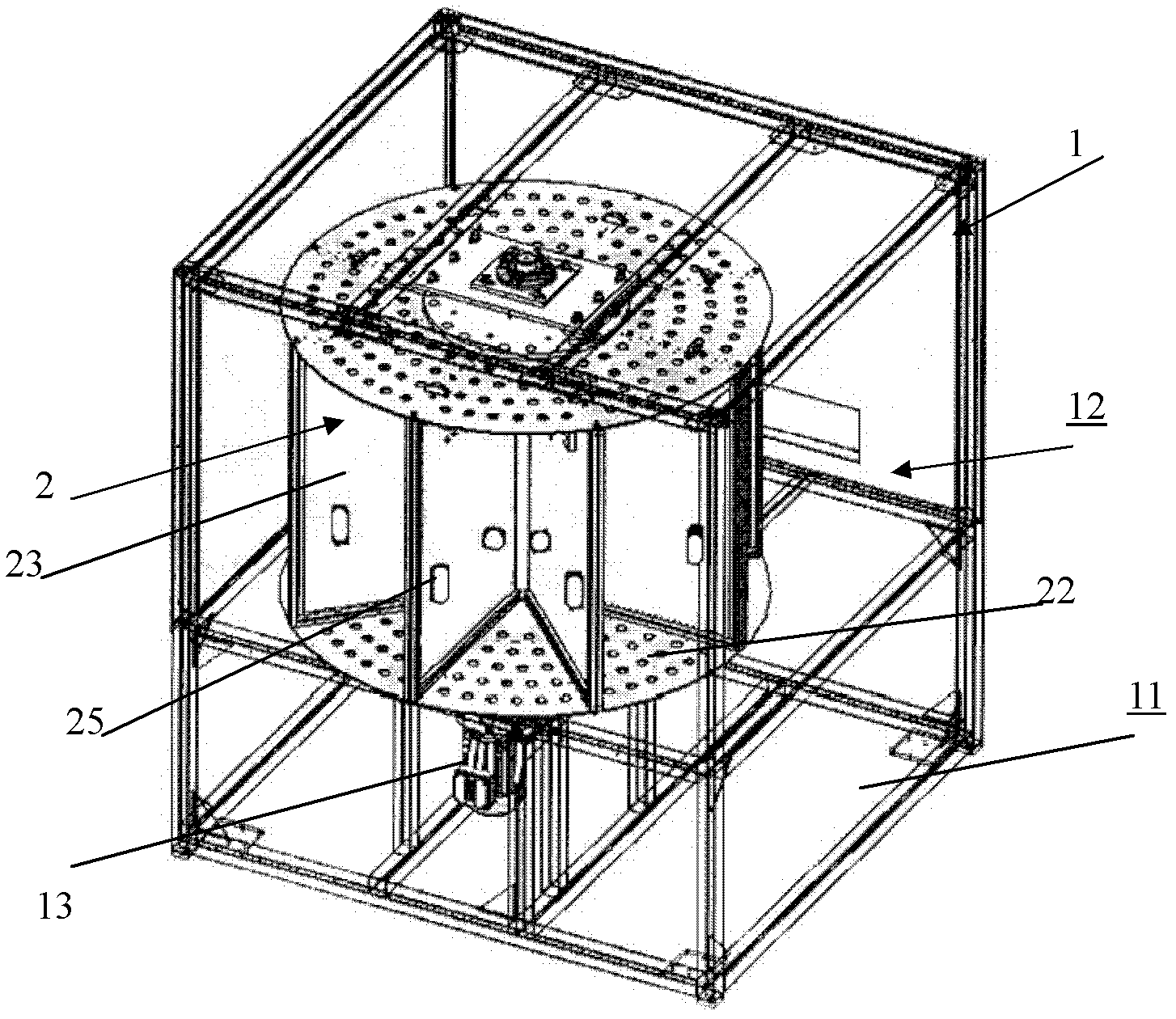

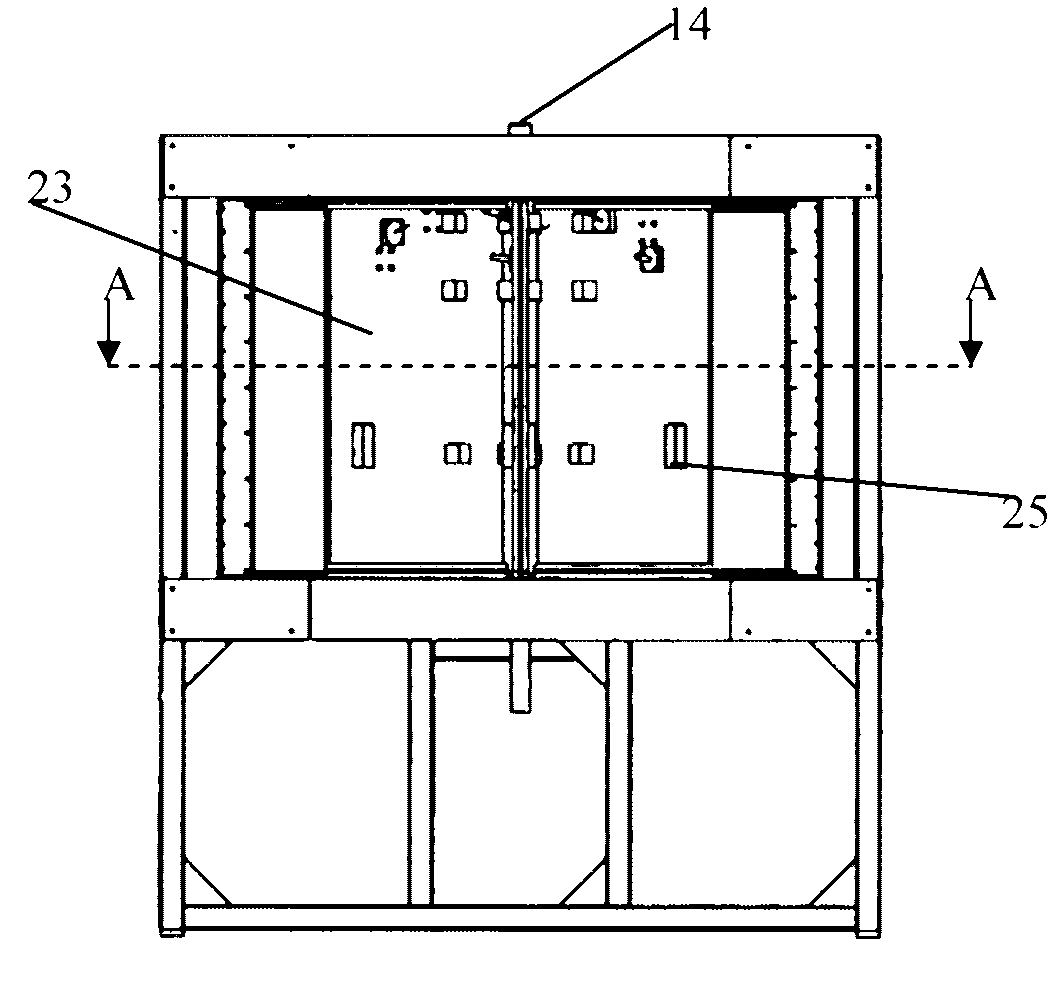

[0020] Such as Figure 1-6 As shown, the rotary drying furnace of the present invention includes a furnace body 1 , a rotary heating frame 2 rotatably arranged inside the furnace body, and an air heating circulation device 3 .

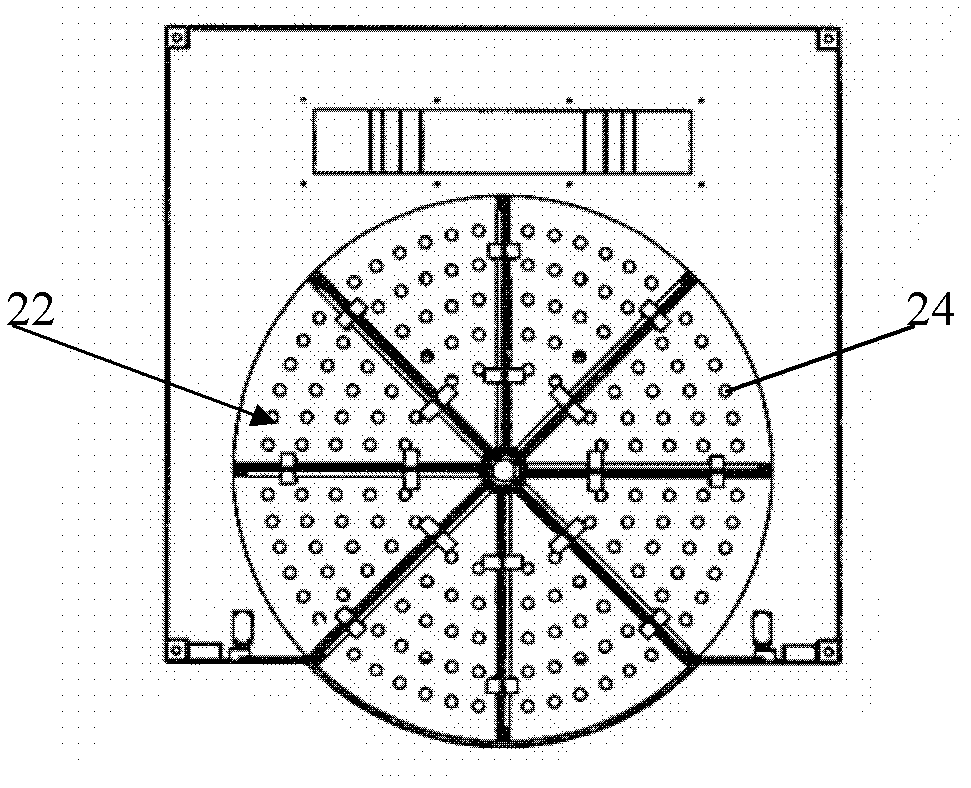

[0021] The rotating heating rack 2 includes a rotating shaft 21 that is rotatably connected to the upper and lower side walls of the heating chamber at its upper and lower ends, and circular support plates 22 that are fixed at the upper and lower ends of the rotating shaft 21 perpendicular to the rotating shaft, 8 rectangular hanging plates 23 arranged between the two support plates parallel to the rotation axis, the rectangular hanging plates are symmetrically spaced and fixedly arranged between the two support plates, and the upper and lower sides are respectively fixedly connected with the upper and lower support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com