Hatching egg turnover vehicle

A turnover vehicle and egg technology, applied in the field of transportation equipment, can solve the problems of high time cost, labor cost and packaging material cost, occupying the transportation space of the transportation vehicle, and the labor intensity of the operator is high, so as to improve the safety and hatching effect. The effect of reducing labor costs and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

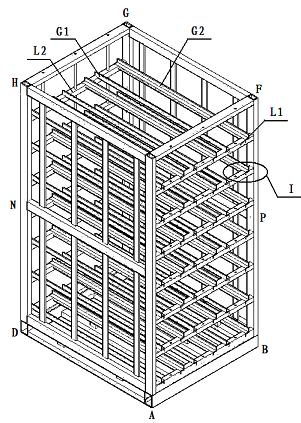

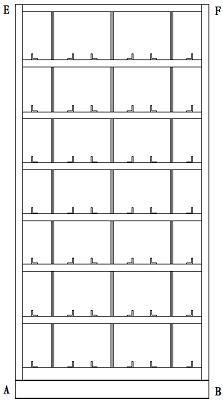

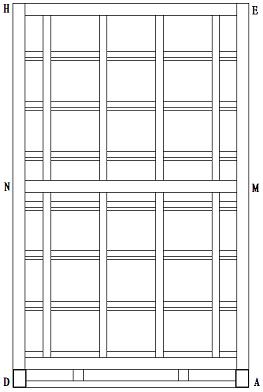

[0029] In order to better explain the present invention and understand it better, the present invention will be described in more detail below through specific embodiments in conjunction with the accompanying drawings.

[0030] see Figure 1 to Figure 7 , the present invention provides an egg turnover vehicle, comprising several layers of horizontally arranged egg tray brackets, said egg tray brackets including one or more sets of egg trays for placing egg trays and allowing the egg trays to slide in and out. Egg tray slide.

[0031] The number of layers of the egg tray support is preferably 7 layers, and the layer height can be 240mm. It is advisable to stack 3 layers of egg trays in each layer, so as to avoid the bottom layer of eggs being crushed when the stack is too high, especially It can avoid excessive pressure on the bottom layer of eggs caused by unforeseen circumstances such as bumps, and ensure the safety of egg transportation. It can also be adapted to the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com