Improved tea vacuum sealing device

A vacuum sealing and improved technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as seal deviation, and achieve the effect of avoiding position deviation, simple structure and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

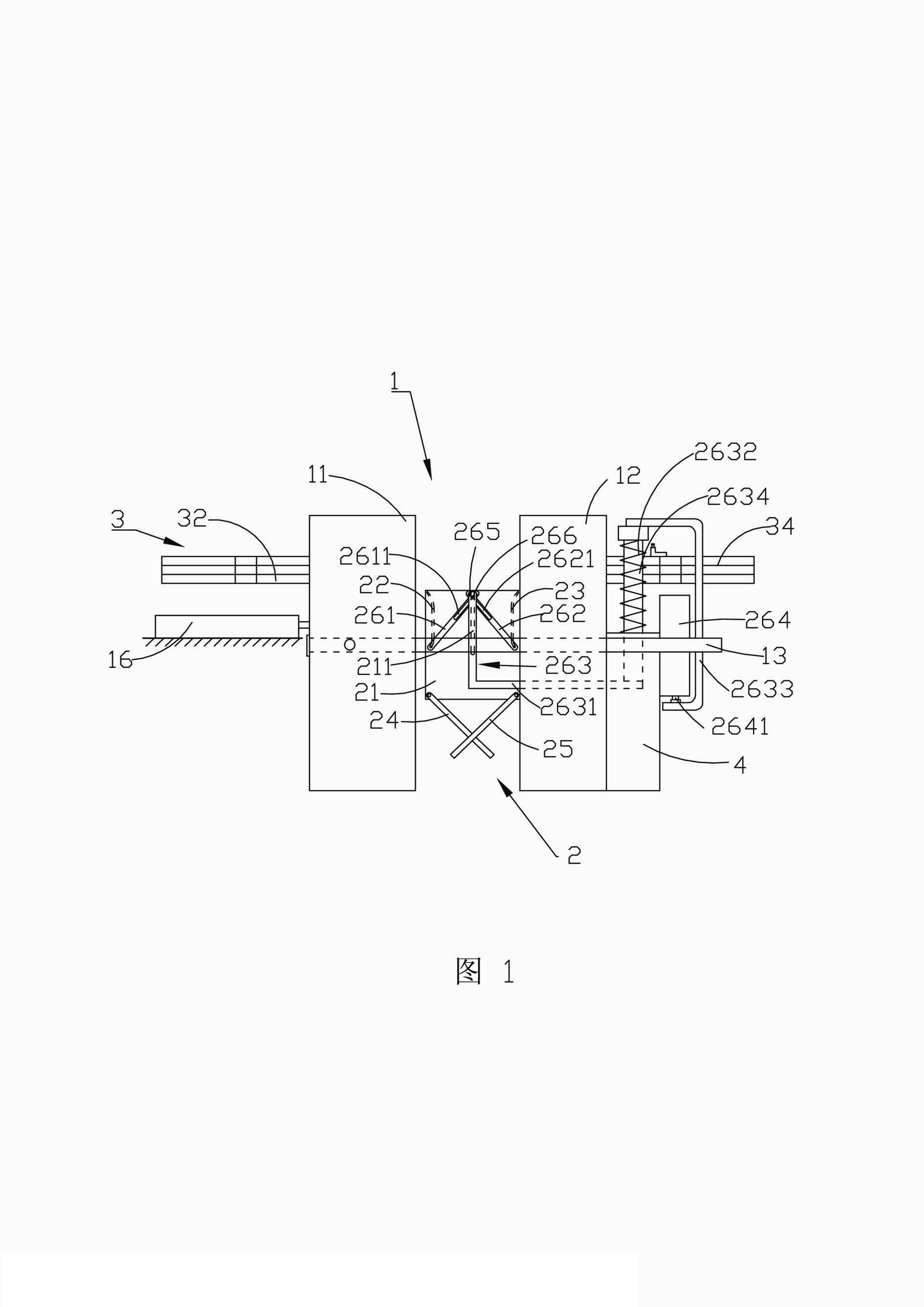

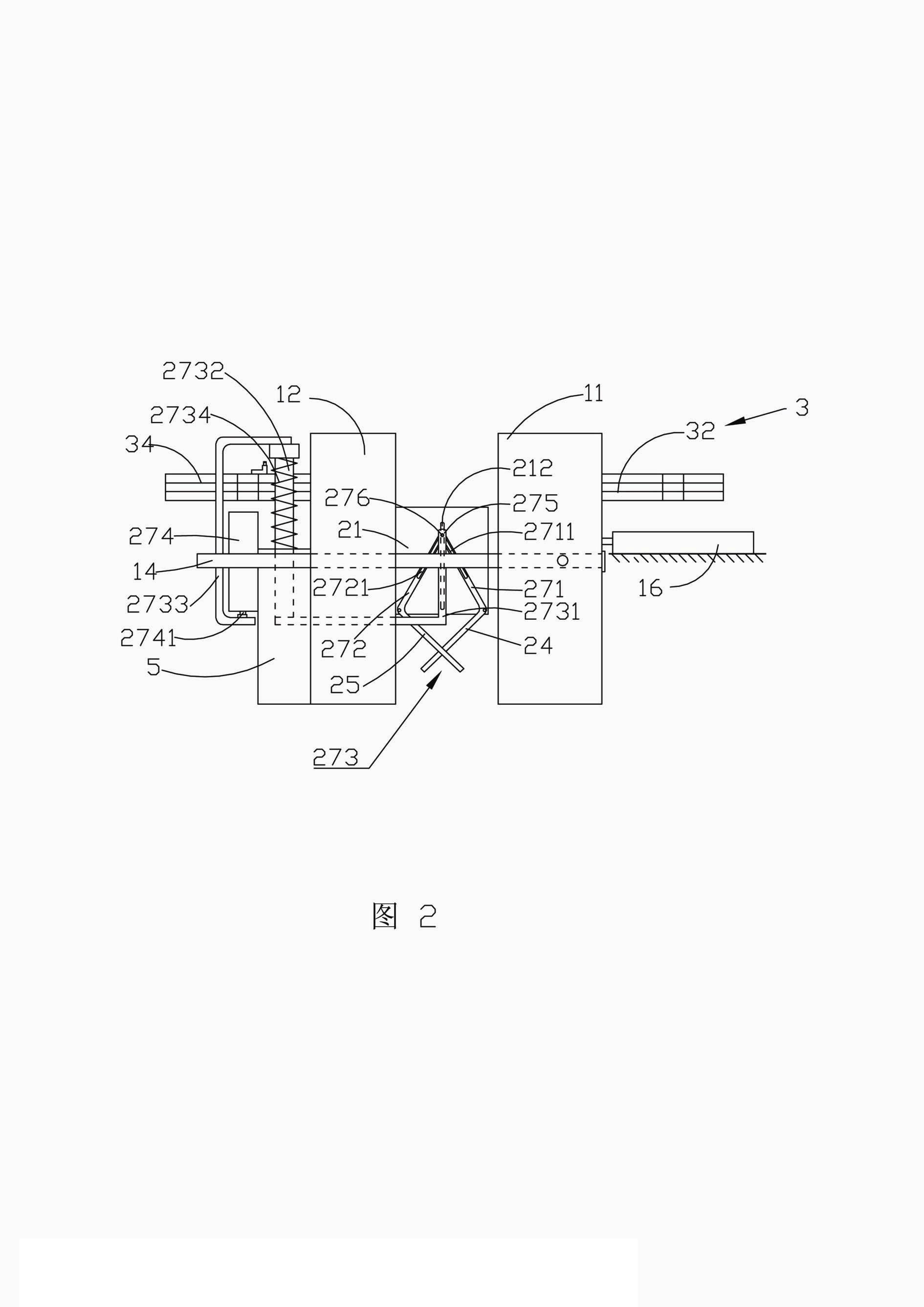

[0029] reference figure 1 , figure 2 . An improved tea vacuum sealing device, comprising an air extraction mechanism 1, a receiving mechanism 2 for packaged tea leaves in the air extraction mechanism 1, and a tea outer bag heat sealing mechanism 3. The receiving mechanism 2 includes a fixed in the air extraction mechanism 1 The upper and lower conductive housing 21, the inclined plates 22, 23 that are arranged in the upper part of the housing 21 and are rotatably connected to the housing 21, which can compress the unsealed tea outer bag, and are rotatably connected to the bottom of the housing 21 Two positioning plates 24, 25 for receiving the sealed tea outer bag, a driving mechanism for driving the two inclined plates 22, 23 to rotate, and a driving device for driving the positioning plates 24, 25 to rotate.

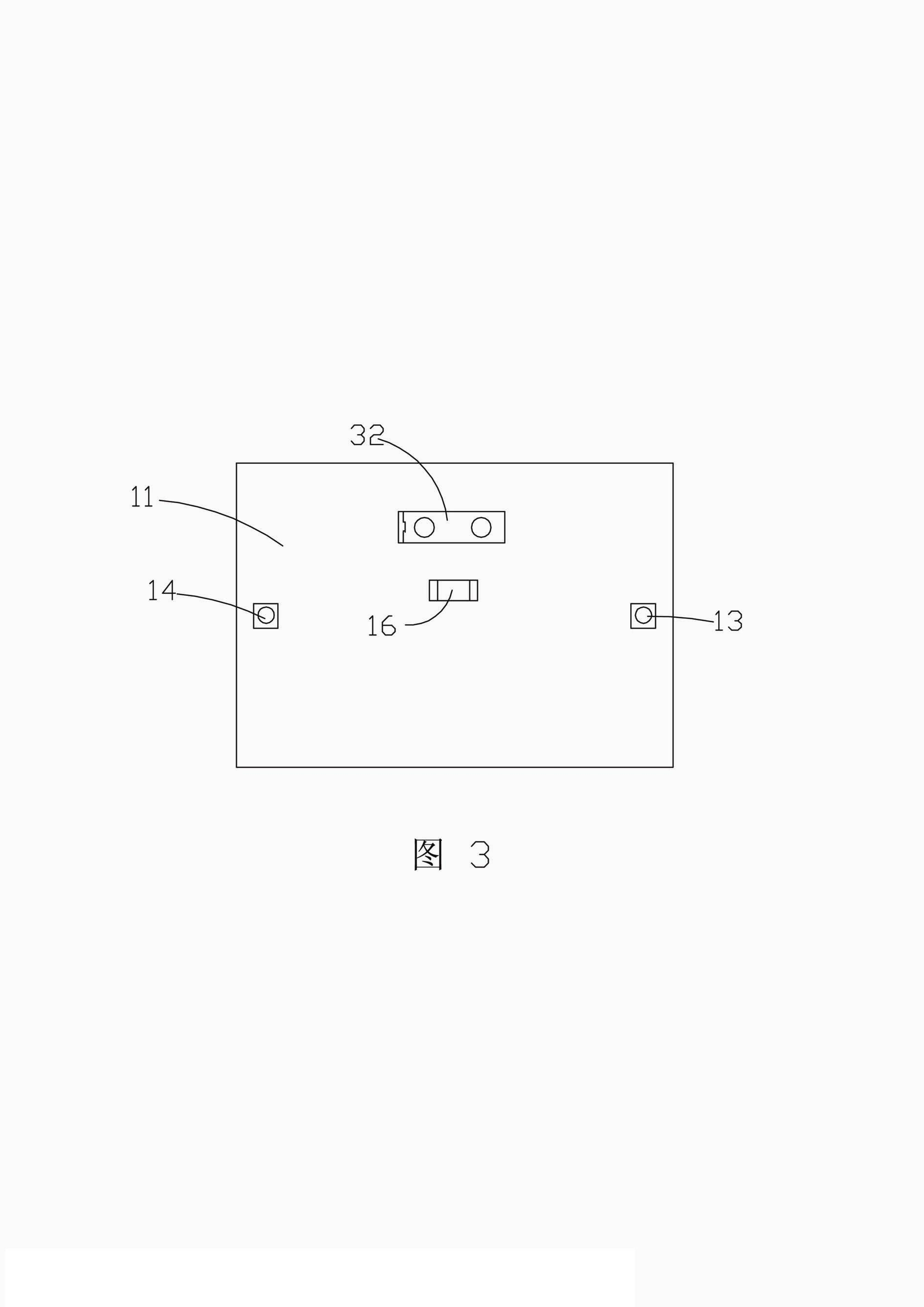

[0030] reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 The air extraction mechanism 1 includes a left shell 11, a right shell 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com