Marine paint spraying dust removal device

A dust removal device and marine technology, applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of sticky paint film, poor dust absorption effect, affecting appearance effect, etc., and achieve good effect and dust absorption thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

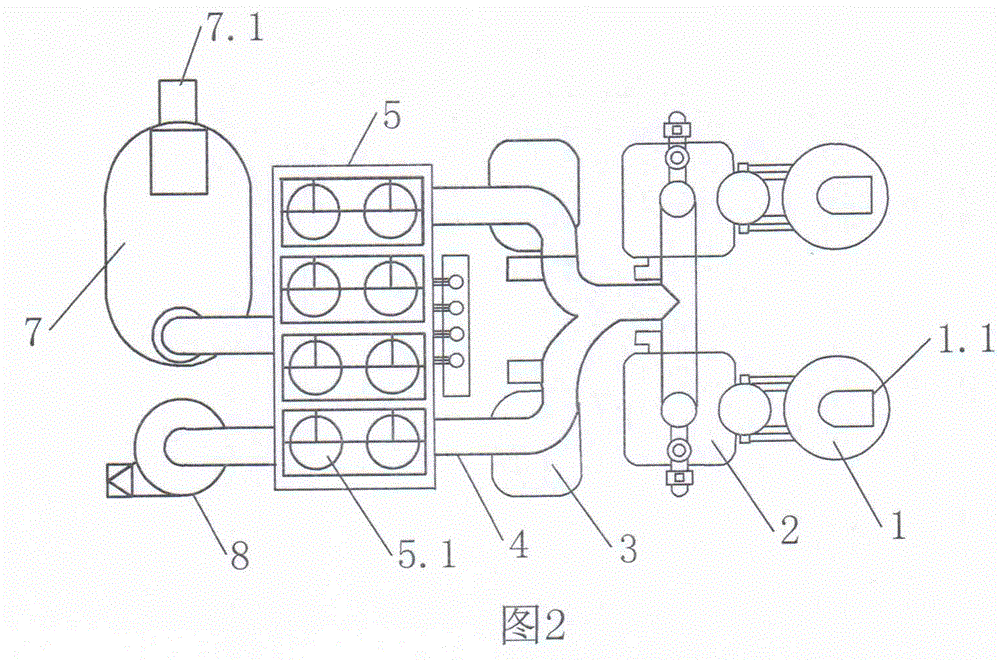

[0022] 1. Hull spraying workshop: The spraying room is 33 meters wide and 42 meters deep, which can accommodate two hull sections to work at the same time. For the convenience of vacuuming, a vacuum port is set at 3.6 meters according to the general standard. A total of 22 vacuum ports can be installed on both sides of the spray booth, so that there are about 10 vacuum ports around each section;

[0023] 2. Arrangement of dust pipelines: Dust pipelines are installed on both sides of the paint spraying room. The main pipelines of dust pipelines are made of Φ114mm steel pipe δ=5mm, and flanged heads are installed 5m away from the direction of the gate, and 4m away from the inner wall. Install a 45° oblique tee stuffy cover flange head at the place. 10 Φ50mm dust suction ports are evenly distributed on the dust conveying main road at an interval of 3.6m, and a Φ50 stop valve is installed in front of each interface.

[0024] 3. Two Φ200 butterfly valves are installed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com