Watertight connector with skeleton-free structure

A watertight connector without skeleton technology, which is applied in the connection, parts of the connection device, contact parts, etc., can solve the problems of degumming and separation between the positioning skeleton and the rubber, short plugging life, and increased contact resistance of the connector. Overcome the defects of rigid plug-in design, prolong the life of plug-in and plug-in, and ensure the effect of water sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

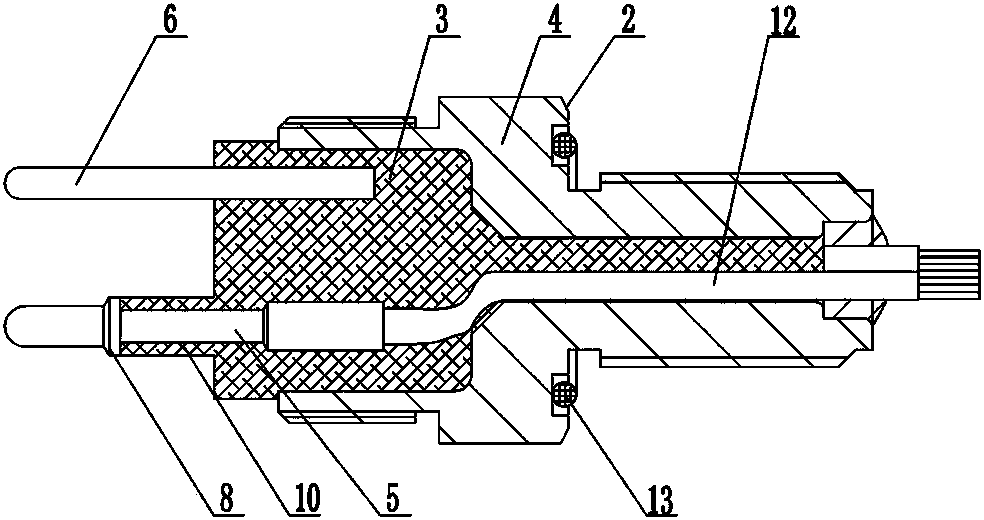

[0035] Such as figure 1 , figure 2 , image 3 As shown, the watertight connector without a skeleton structure includes a plug 1 and a socket 2. The socket 2 includes an insulating body A3, a set of pins 5, and at least one positioning pin 6. The terminal of the pin 5 is connected with a polyfluorine sheath core Wire 12, each wire is connected to a conductive pin 5, and the other end of the core wire 12 is connected to the electrical equipment in the deep-sea pressure chamber. For the transmission of power and signals, the pin 5, the positioning pin 6 and the polyfluorine sheathed core wire 12 are integrally formed with the insulating body A3 through injection vulcanization;

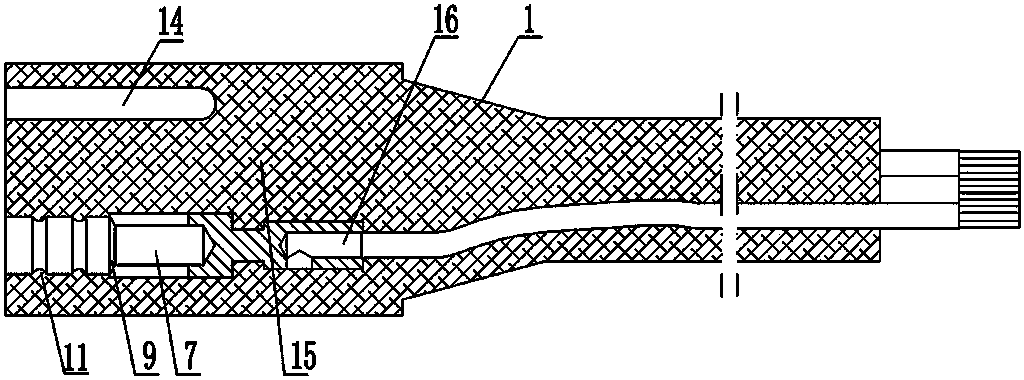

[0036] The plug 1 includes an insulating body B15, a set of jacks 7 matching the pins 5 and a positioning pin jack 14 matching the positioning pins 6, the terminals of the jacks 7 are connected with a watertight cable 16, the jacks 7, the positioning pin sockets The hole 14 and the watertight cable 16...

Embodiment 2

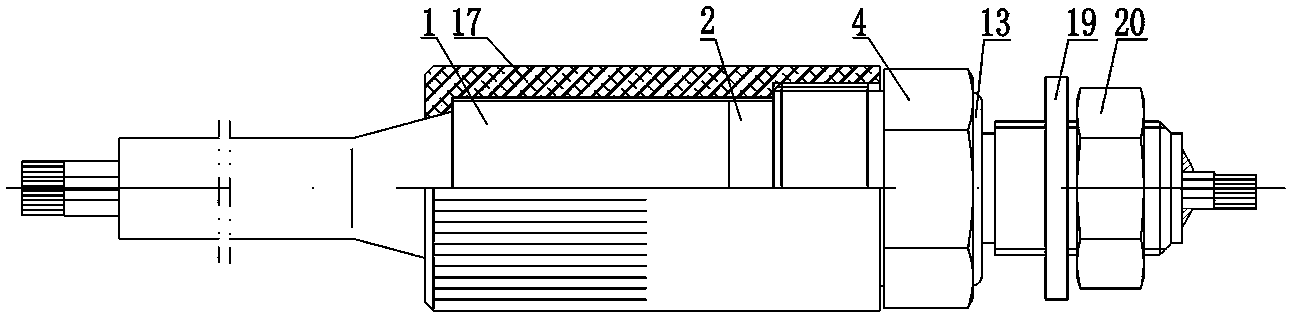

[0042] Such as figure 2 , Figure 4 As shown, the watertight connector without a skeleton structure includes a plug 1 and a socket 2. The socket 2 includes an insulating body A3, a set of pins 5, and at least one positioning pin 6. The terminal of the pin 5 is connected with a polyfluorine sheath core Line 12, each wire is connected to a pin 5, and the other end of the core wire 12 is connected to the electrical equipment in the deep-sea pressure chamber. The signal transmission function, the pin 5, the positioning pin 6 and the polyfluorine sheath core wire 12, are integrally formed with the insulating main body A3 through injection vulcanization;

[0043] The plug 1 includes an insulating body B15, a set of jacks 7 matching the pins 5 and a positioning pin jack 14 matching the positioning pins 6, the terminals of the jacks 7 are connected with a watertight cable 16, the jacks 7, the positioning pin sockets The hole 14 and the watertight cable 16 are integrally formed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com