Air flow sampling device for pulverizing system and sampling method thereof

A technology of pulverizing system and sampling device, applied in the direction of sampling device, etc., can solve the problems of blockage of sampling device, inconvenient monitoring of airflow sampling and inability to blow through the pulverizing system, etc., and achieve the effect of smooth sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below.

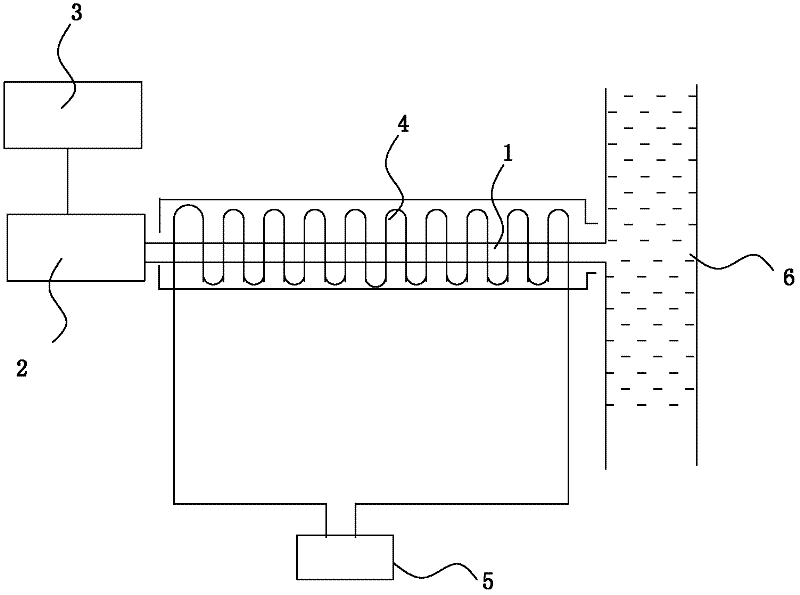

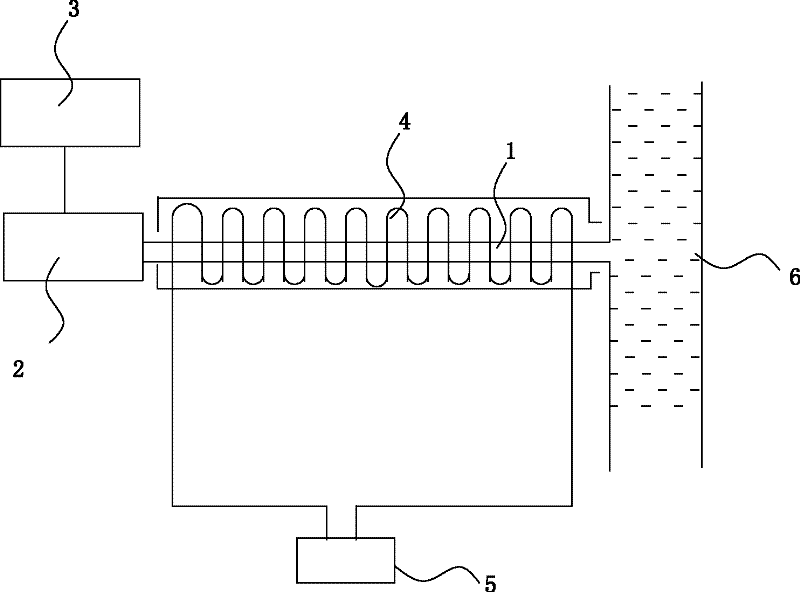

[0019] Such as figure 1 , an airflow sampling device for a pulverizing system, comprising a sampling pipeline 1, an airflow pretreatment device 2, and an airflow terminal analysis device 3. Sampling pipeline 1 is used to connect the pulverizing system. One end of the airflow pretreatment device 2 is connected to the sampling pipeline 1 , and the other end of the airflow pretreatment device 2 is connected to the airflow terminal analysis device 3 . The airflow pretreatment device 2 is used to remove impurities such as dust contained in the airflow. The gas flow terminal analysis device 3 is used for comprehensive analysis of gas components in the sampling pipeline.

[0020] A heating and heat preservation device 4 is arranged on the sampling pipeline 1 . The heating and heat preservation device 4 is arranged on the outer surface of the sampling pipeline 1. The heating and heat preservation devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com