Glass tube automatic conveyer device of thermometer production line

An automatic conveying device and production line technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as high labor intensity, threat to worker safety, long length, etc., to achieve reduced labor intensity, high operability, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

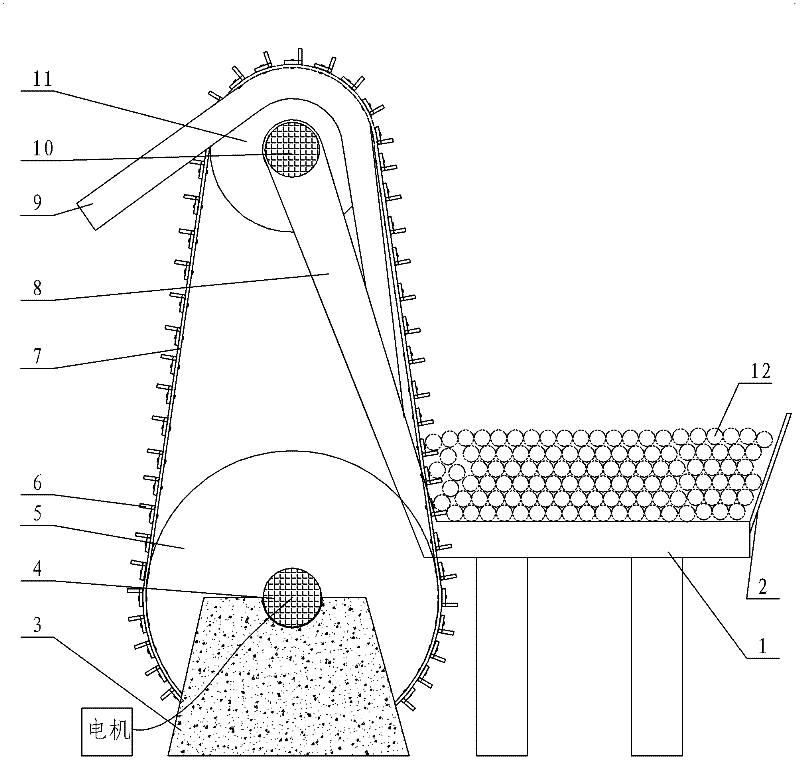

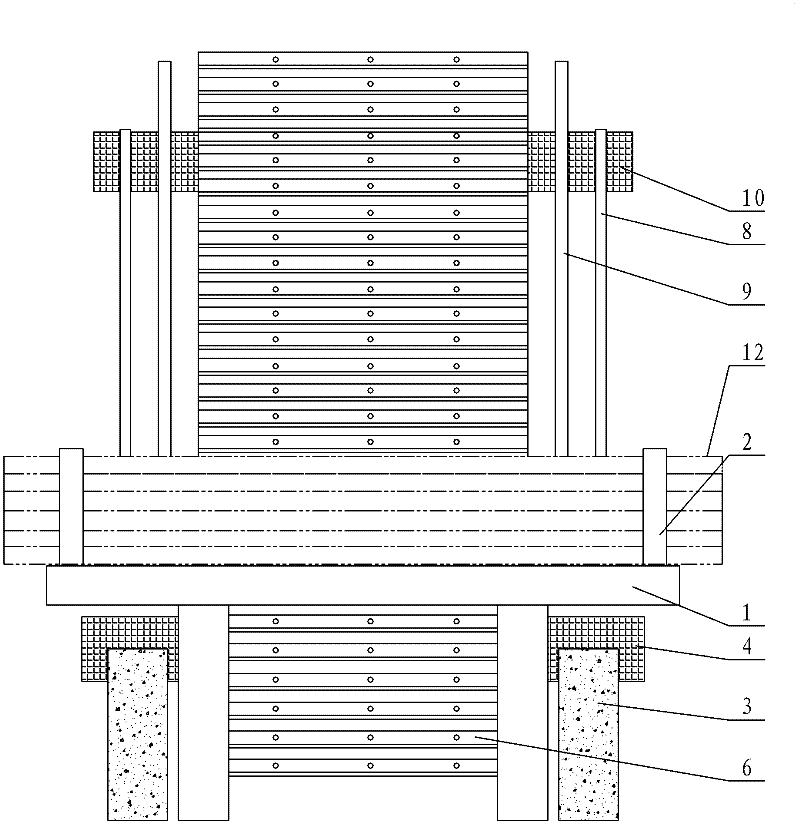

[0015] Such as figure 1 and 2 In the shown embodiment, the glass tube automatic conveying device of the thermometer production line according to the present invention includes a workbench 1, two parallel support plates 8 are arranged on one side of the upper part of the workbench 1, and a rotating shaft b10 is arranged at one end of the supporting plate 8, and the rotating shaft b10 The transmission wheel 11 is arranged on the top, and the lower side of the transmission wheel 11 is provided with two parallel bases 3, and a semi-arc groove is arranged on the base 3, and the rotating shaft a4 is placed in the semi-arc groove, and the driving wheel 5 is arranged on the rotating shaft a4 A circle of transmission belt 7 is set on the transmission wheel 11 and the driving wheel 5, and the transmission belt 7 is connected with several cross-sections of L-shaped transport plates 6 by screws.

[0016] During transportation, firstly, a number of long glass tubes 12 are placed on the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com