Theodolite-based large-scale spherical tank pillar verticality on-line accurate measurement method

An accurate measurement, theodolite technology, applied in the theodolite and other directions, can solve problems such as the impracticality of the hanging wire method, the qualified data exceeding the standard tolerance, and the deviation of the hanging wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following, the present invention will be further described in combination with specific embodiments:

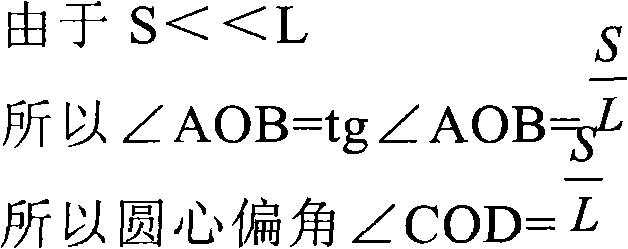

[0031] Such as figure 1 - figure 2 As shown, for a 3000 cubic meter spherical tank with 12 pillars, the radial and circumferential verticality of its pillars need to be measured. The following takes No. 10 and No. 7 pillars as examples to illustrate the radial verticality and circumference. Accurate measurement method of verticality.

[0032] figure 1 The center line AB is the common tangent of the bottom cross-section circle of the No. 4 pillar and the No. 10 pillar (the center of the sphere is opposite to the pillar), the line CD is the parallel line of AB, and the CD is the tangent of the bottom cross-section circle of the No. 7 pillar. When measuring the circumferential verticality of No. 10 pillar, set the theodolite on the B end of line AB (when measuring the circumferential verticality of No. 4 pillar, set the theodolite on the A end of AB line); when measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com