Radiator fan

A heat dissipation fan and fan wheel technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., and can solve problems such as inconvenient assembly and use, turbulence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

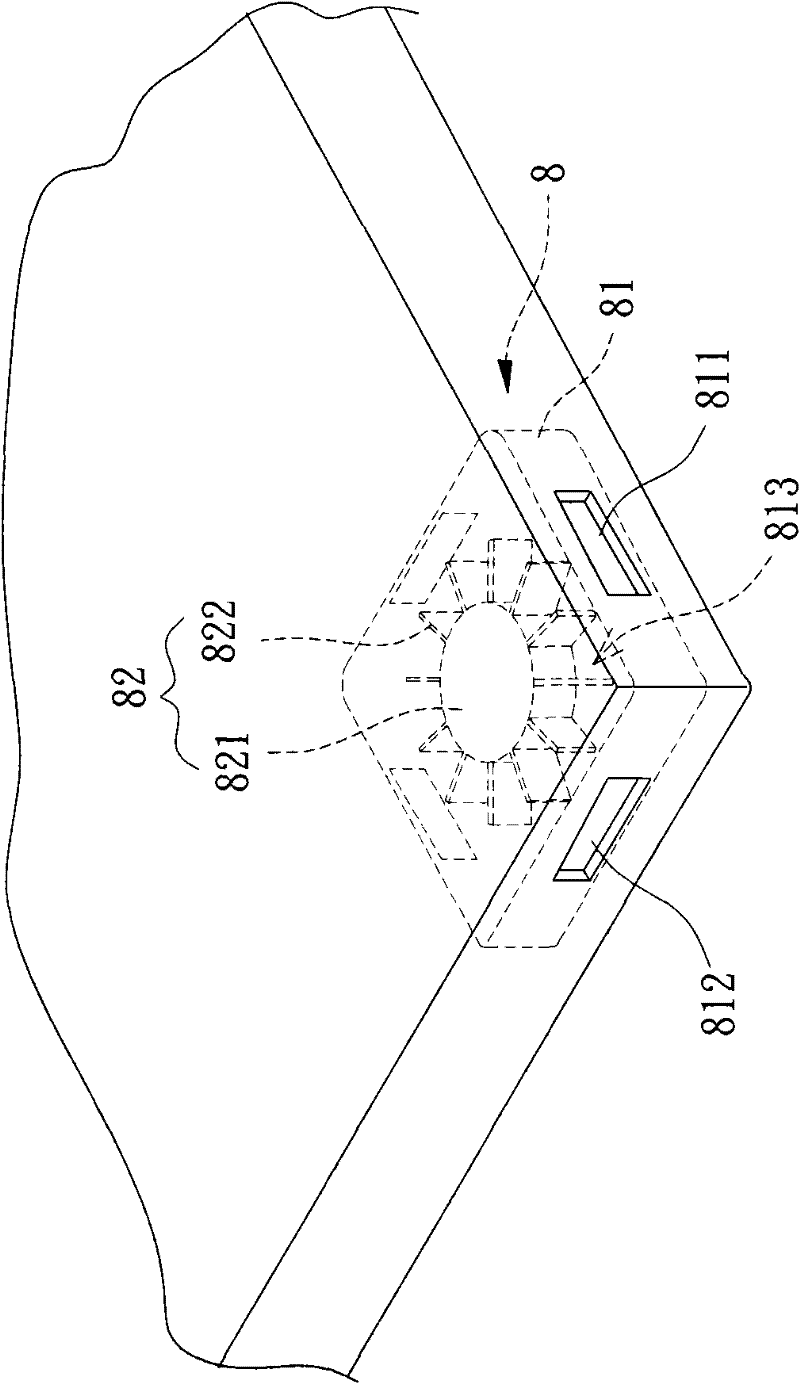

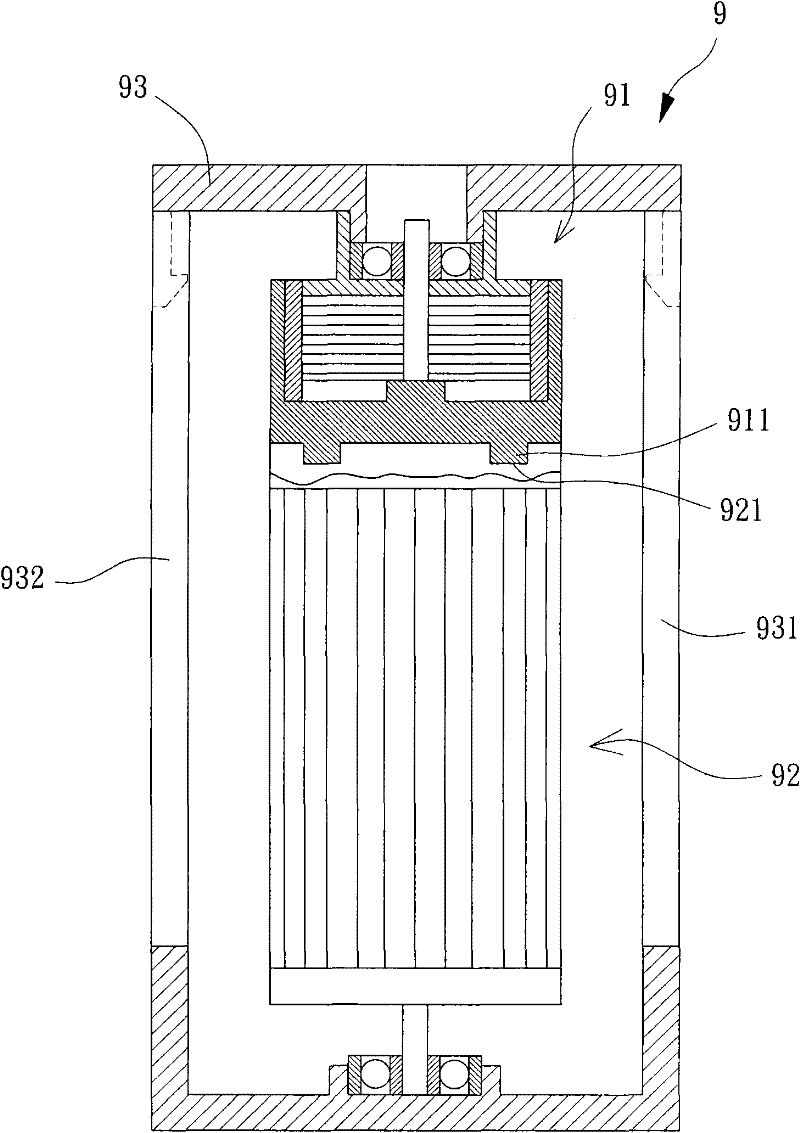

[0038] Please refer to image 3 and 4 As shown, the cooling fan according to the first embodiment of the present invention includes a fan frame 1 and a motor 2 . The fan frame 1 is a frame structure capable of allowing airflow to flow in a radial direction; the motor 2 is combined inside the fan frame 1 .

[0039] The fan frame 1 can be any hollow frame structure capable of accommodating the motor 2 and allowing air flow to be introduced and exported in a radial direction. Wherein the fan frame 1 at least includes a receiving portion 1a, a closing portion 1b and a side wall portion 1c, the receiving portion 1a is spaced opposite to the closing portion 1b, and the side wall portion 1c is located between the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com