Traction type rolling welding machine

A rolling welding machine and traction type technology, applied in the direction of roller electrode welding, welding equipment, resistance welding equipment, etc., can solve the problem that the pusher plate and the main plate cannot be rotated precisely synchronously, the longitudinal bars of the steel cage are twisted radially, and the twist bars And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

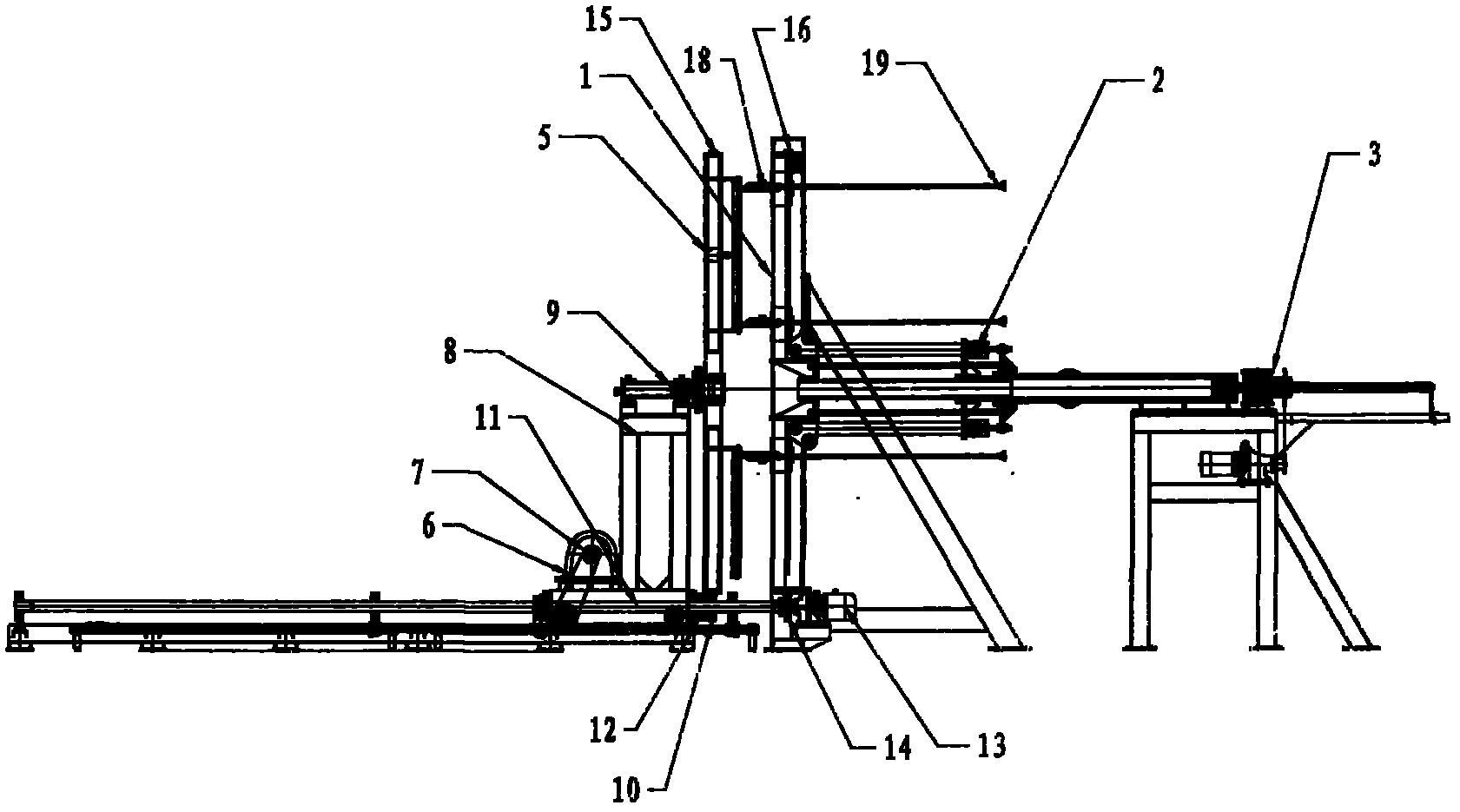

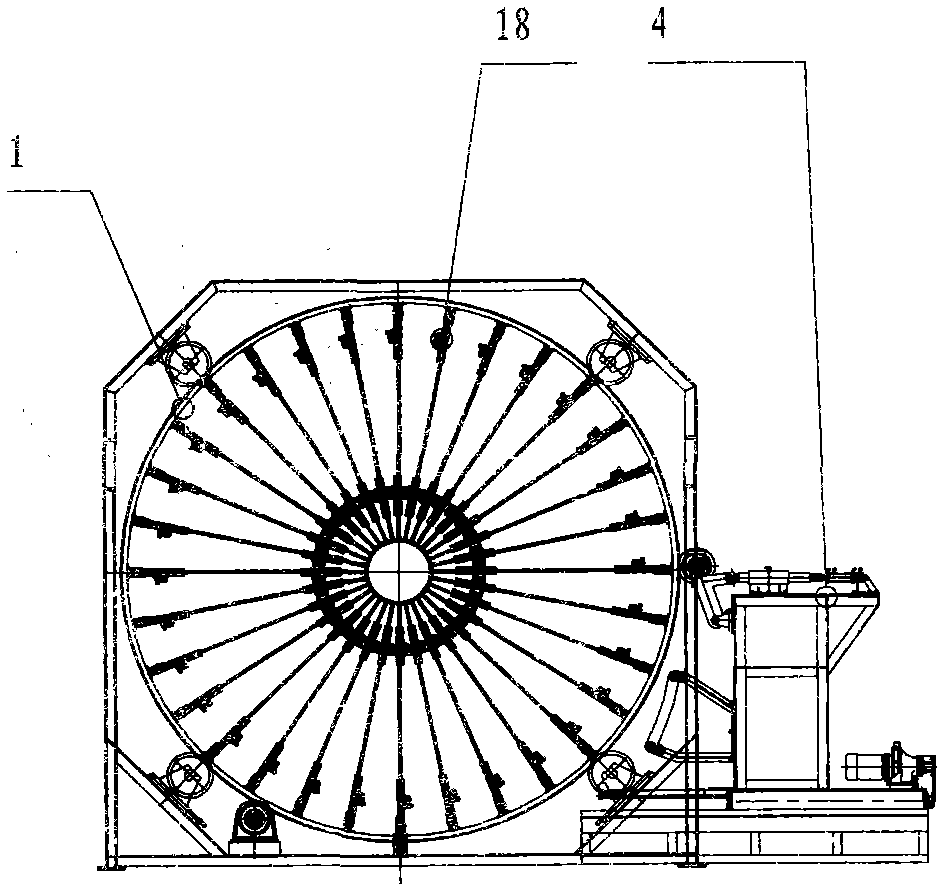

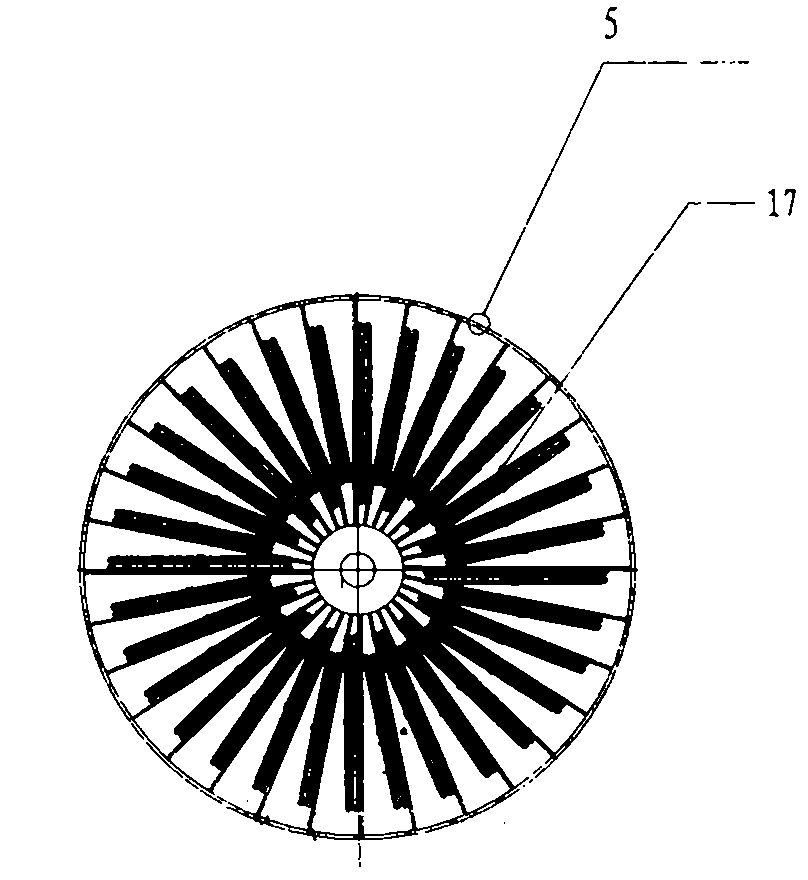

[0010] Such as figure 1 As shown, the traction type seam welding machine of the present invention includes a main plate 1 , a diameter reducing mechanism 2 of a welding table, a diameter expanding mechanism 3 , a welding mechanism 4 , a traction face plate 5 and a traction trolley 6 . The traction trolley 6 is composed of a driving mechanism 7 and a frame 8. The mandrel 9 of the traction faceplate is connected with the traction trolley frame 8. The transmission sprocket 10 of the traction faceplate 5 is set on the transmission square steel 11 and connected to the traction trolley through the bearing seat 12. Frames 8 are connected, and the traction faceplate drive sprocket is meshed with the chain on the outer circumferential surface of the traction faceplate. When the traction trolley drives the traction faceplate to move axially, the traction faceplate drive sprocket 10 slides on the transmission square steel 11 and keeps The chain 15 on the outer peripheral surface of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com