Pipe fitting for absorbing expansion and earthquake-proof

A pipe joint and shock-resistant technology, applied in the field of pipe joints, can solve the problems of interfering with fluid flow, hindering the smooth flow of fluid, expensive production costs, etc. The effect of shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

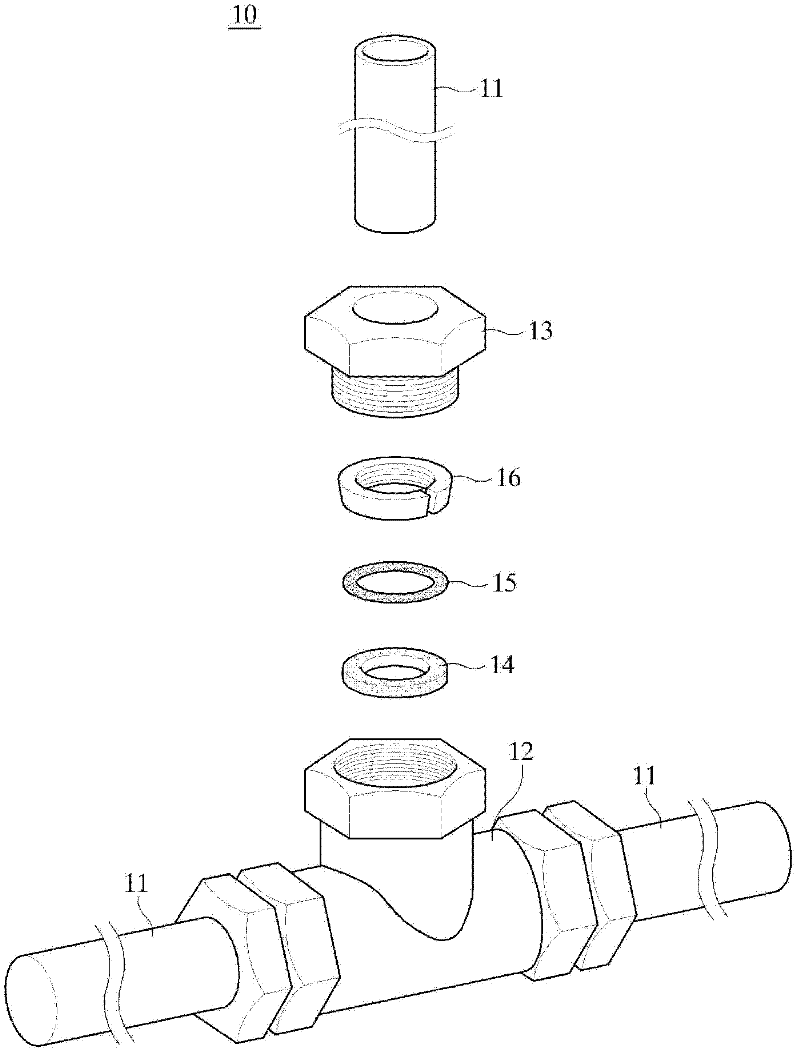

[0069] Hereinafter, the telescopic and earthquake-resistant pipe joint according to the present invention will be described in detail with reference to the drawings.

[0070] image 3 is a schematic perspective view showing a telescopic and shockproof pipe joint according to the present invention, Figure 4 is in image 3 An isolated perspective view of the fitting shown in, Figure 5a and Figure 5b is in image 3 The side sectional view and the use state diagram of the pipe joint shown in Figure 6a and Figure 6b is shown in Figure 4 A side sectional view of the cap and pressurized parts shown in .

[0071] First, if Figure 3 to Figure 4 As shown in the figure, the flexible and shockproof pipe joint 100 according to the present invention includes:

[0072] A tube body 110, which can be inserted into one end of a plurality of tubes 101, and a receiving hook 111 is formed on the inner periphery of the end of the inserted tube 101 to expand the inner diameter;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com