Loaded zinc trifluoromethanesulfonate catalyst, its preparation method, and preparation method of butanone-glycol ketal

A technology of zinc trifluoromethanesulfonate and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., and can solve the problems of low product purity, equipment corrosion, and environmental problems. Pollution and other problems, to achieve good catalytic performance and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a method for preparing the catalyst, wherein the method comprises: impregnating the mesoporous silica carrier with a zinc trifluoromethanesulfonate solution, so that the zinc trifluoromethanesulfonate is supported on the mesoporous silica On the carrier, the loading of the zinc trifluoromethanesulfonate is such that in the obtained catalyst, based on the total weight of the catalyst, the content of the zinc trifluoromethanesulfonate is 10-60% by weight, and the mesoporous dioxide The content of the silicon carrier is 40-90% by weight. More preferably, based on the total weight of the catalyst, the content of the zinc trifluoromethanesulfonate is 10-15% by weight, and the content of the mesoporous silica carrier is 85-90% by weight.

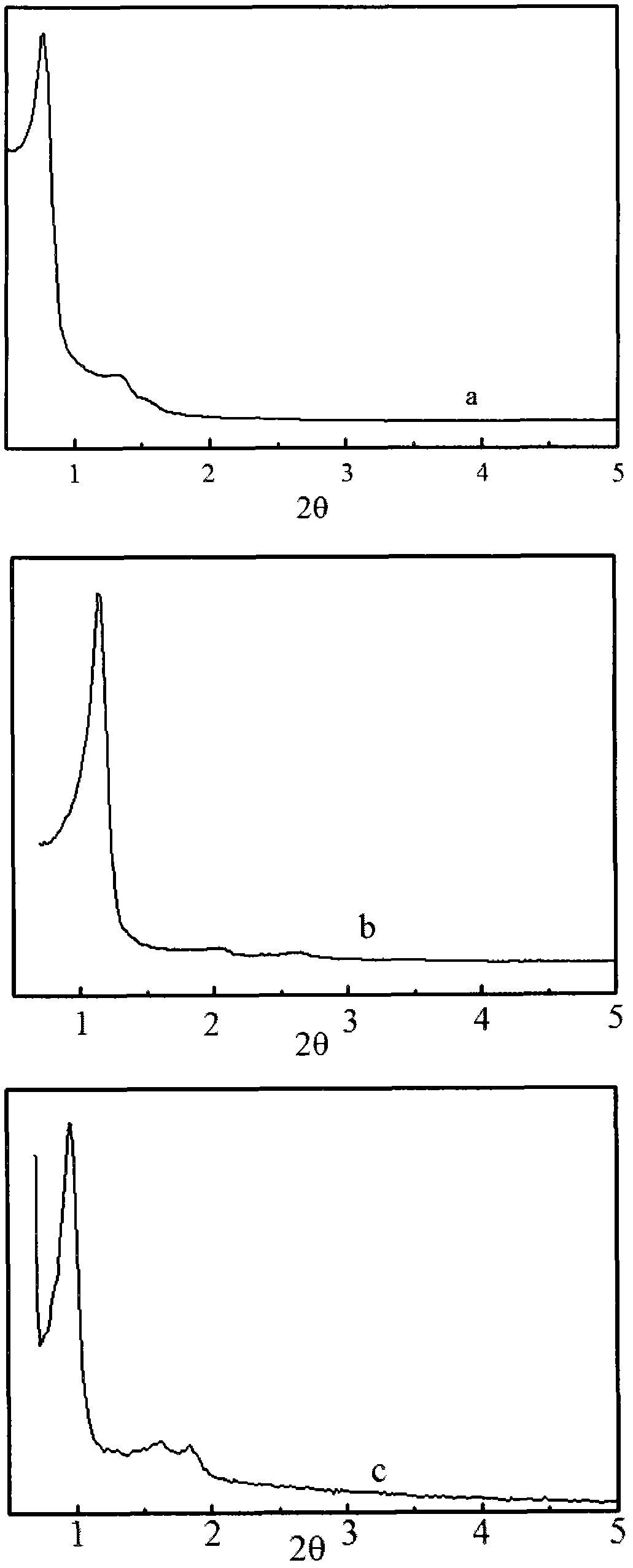

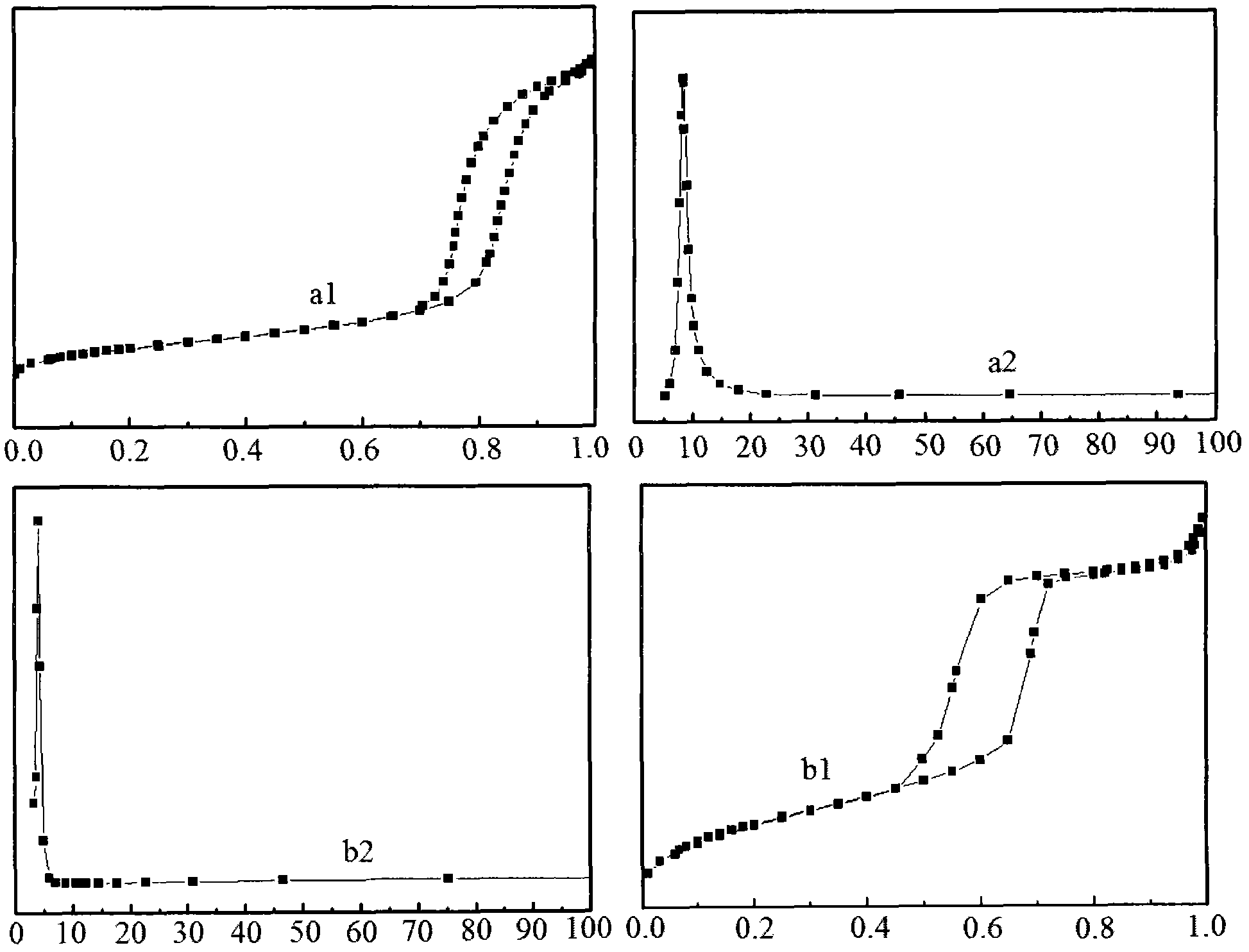

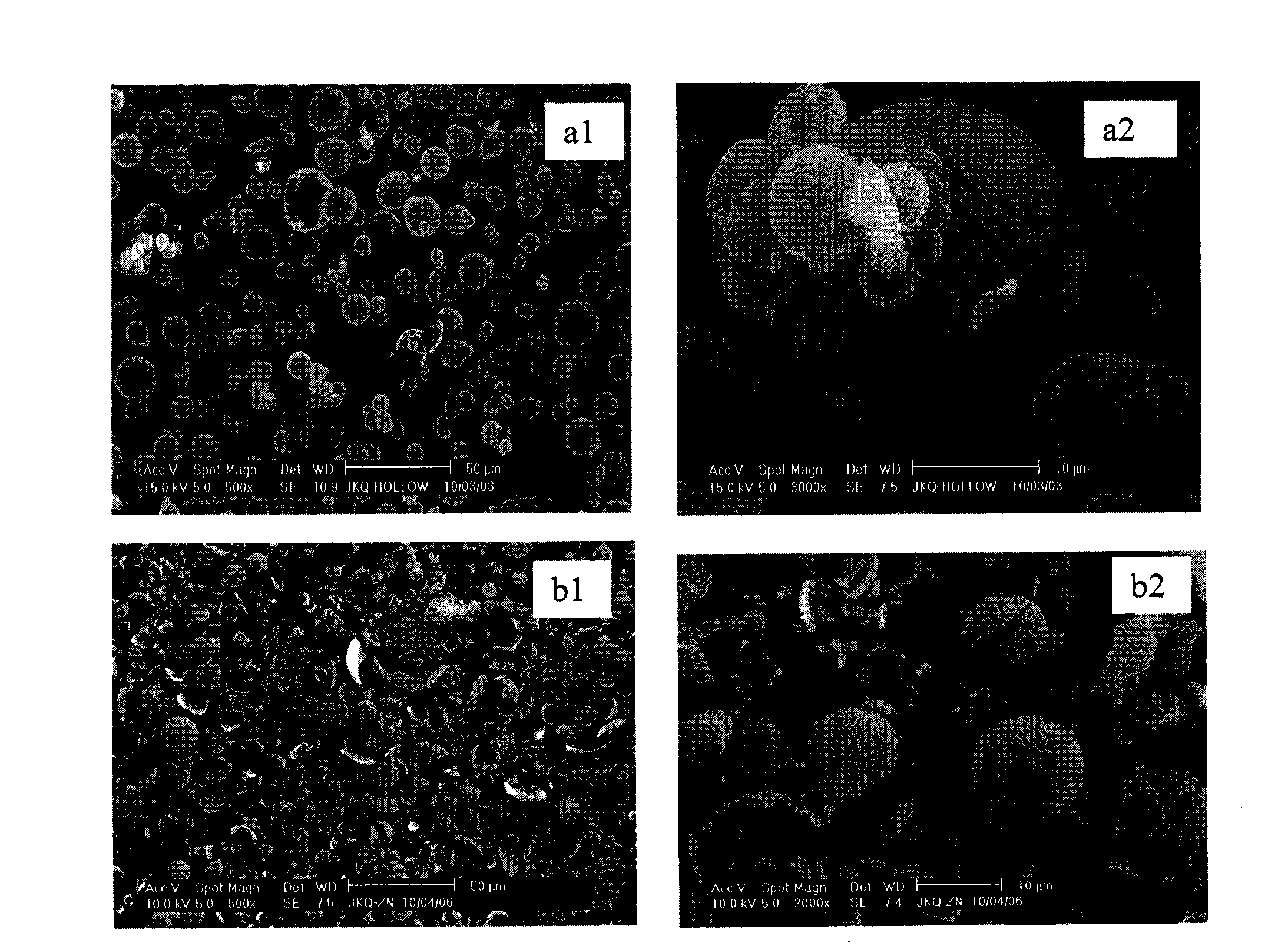

[0019] The size of the hollow spherical mesoporous silica can be changed in a wide range, preferably, the diameter of the hollow spherical mesoporous silica carrier is 3-20 microns, and the specific surfa...

Embodiment 1

[0035] Add 1.0 gram of three-stage copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (Aldrich, P123) and 1.69 gram of ethanol into the buffer solution of acetic acid and sodium acetate of pH=4.4 of 28ml, stir at 15 ℃ Until the polyoxyethylene-polyoxypropylene-polyoxyethylene is completely dissolved, then add 6g of trimethylpentane to the above solution, stir at 15°C for 8 hours, then add 2.13g of tetramethoxysilane to the above solution After stirring at 15°C for 20 hours, the solution was transferred to a polytetrafluoroethylene-lined reaction kettle, oven crystallized at 60°C for 24 hours, filtered, washed with distilled water, and dried to obtain hollow spherical mesoporous silica Original powder.

[0036] The hollow spherical mesoporous silica raw powder was calcined in a muffle furnace at 550° C. for 24 hours to obtain hollow spherical mesoporous silica (named MS-1).

[0037] Stir 1 gram of hollow spherical mesoporous silica and 1 gram of zinc trifluoromethanesu...

experiment Embodiment 1

[0046] This experimental example is used to illustrate the catalytic activity of the supported zinc trifluoromethanesulfonate catalyst according to the present invention.

[0047] The supported zinc trifluoromethanesulfonate catalyst (MS-Zn) was vacuum-dried at 150°C for 6 hours, and after cooling to room temperature, weighed 0.3 g, then weighed 21.6 g of butanone and 22.3 g of ethylene glycol, and sequentially Put into a 100ml three-necked flask, stir for 4 hours under heating conditions at 120°C, and after cooling to room temperature, centrifuge and analyze the components of the reaction product liquid by gas chromatography. The results are: the content of ethylene glycol is 13% by weight, and the product D The ketone-ethylene glycol ketal content was 41.7% by weight. It is determined through calculation that the catalytic efficiency of the catalyst is 87%, the catalytic selectivity is 99%, and the catalytic yield is 42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com