Double-combined crown spring and jack using same

A joint crown and crown spring technology, which is applied in the field of double crown springs, can solve problems such as stuck crown spring assembly and difficulties, and achieve the effect of simple assembly, uniform distribution of support points, and reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

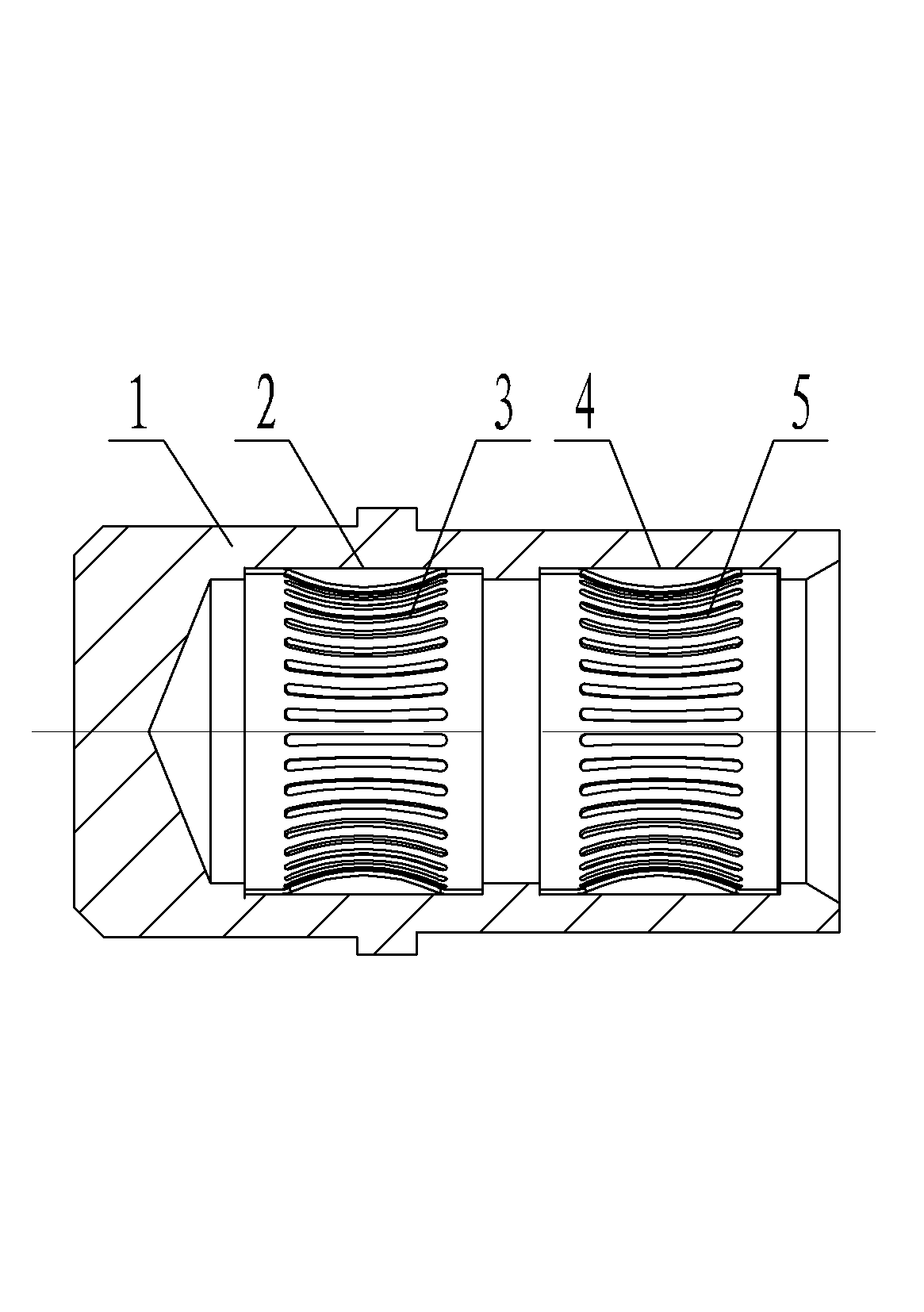

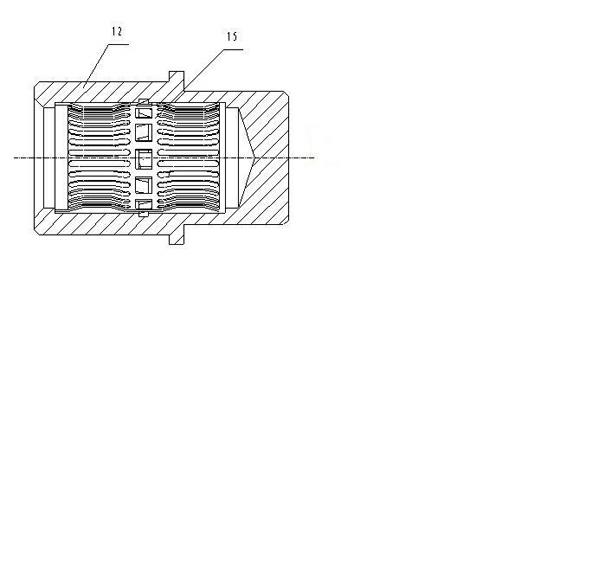

[0024] A kind of embodiment of duplex crown spring 15, in Figure 5 , Image 6 in, combine figure 2 , 3 , 4, the two ends of this duplex crown spring 15 have an end retaining ring 11 respectively, the middle part of the duplex crown spring 15 has a middle retaining ring, and the middle retaining ring and the two end retaining rings 11 are arranged respectively There is a group of crown springs 15 wires 7, wherein one end of one group of crown springs 15 wires 7 is connected to one side of the middle retaining ring, the other end is connected to the end retaining ring 11 of the corresponding side, and the other group of crown springs 15 wires 7 One end is connected to the other side of the middle holding ring, and the other end is connected to the end holding ring 11 on the corresponding side. Two groups of crown springs 15 wires 7 connect the middle retaining ring with two end retaining rings 11 at two ends to form a whole. All the crown springs 15 wires 7 are elastically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com