Guide plate

一种导向板、导向链的技术,应用在导向板领域,能够解决增加发热及噪音、偏磨损、不能完全防止弓状变形导向板弓状弯曲等问题,达到抑制弓状变形、防止弓状变形的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Hereinafter, the guide plate in the Example of this invention is demonstrated based on drawing.

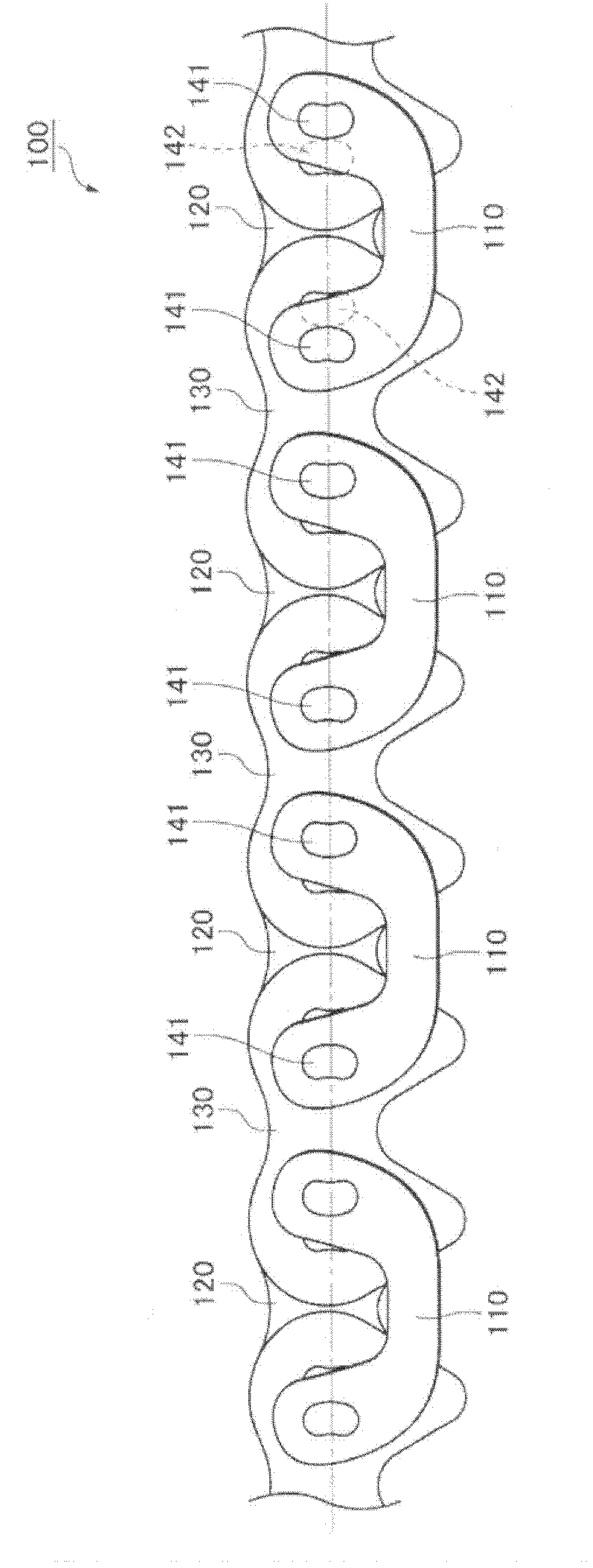

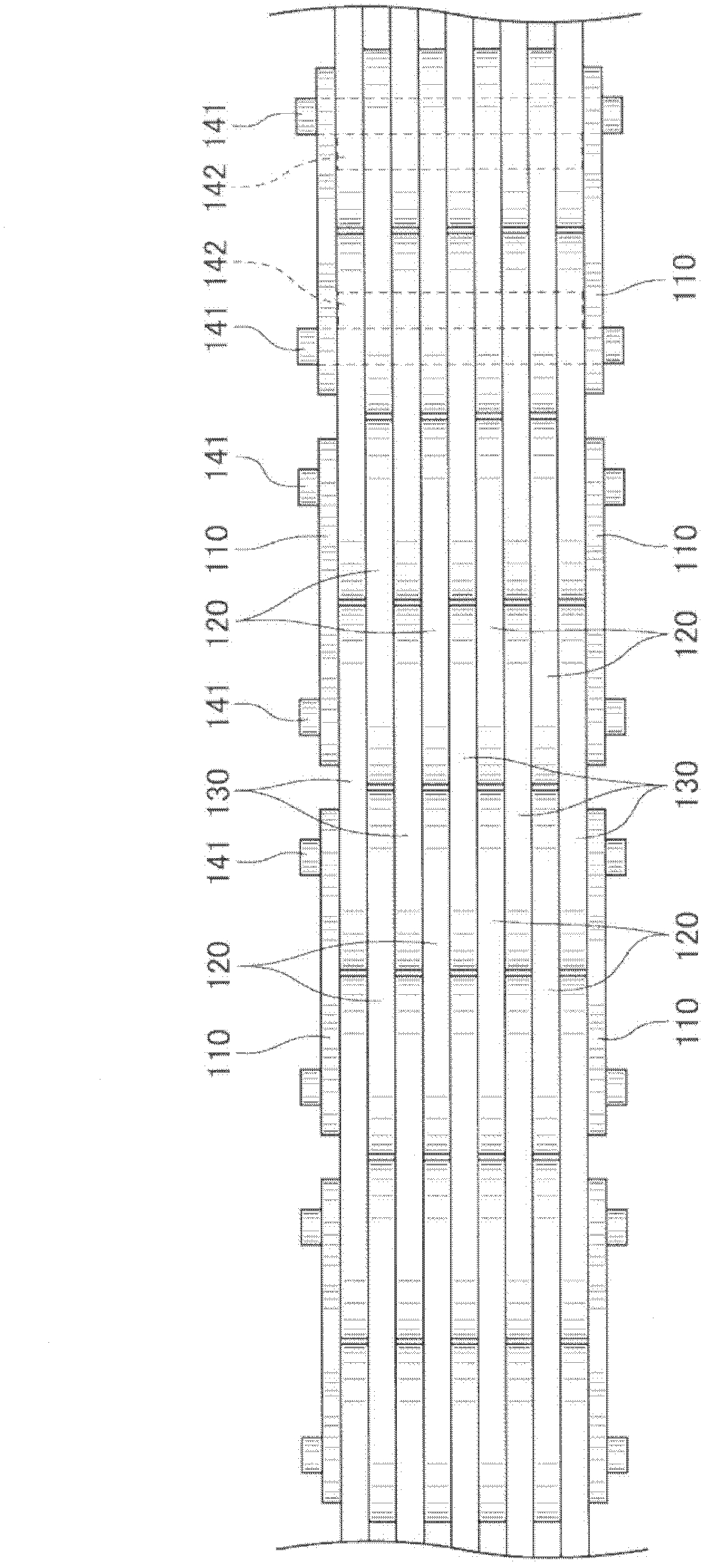

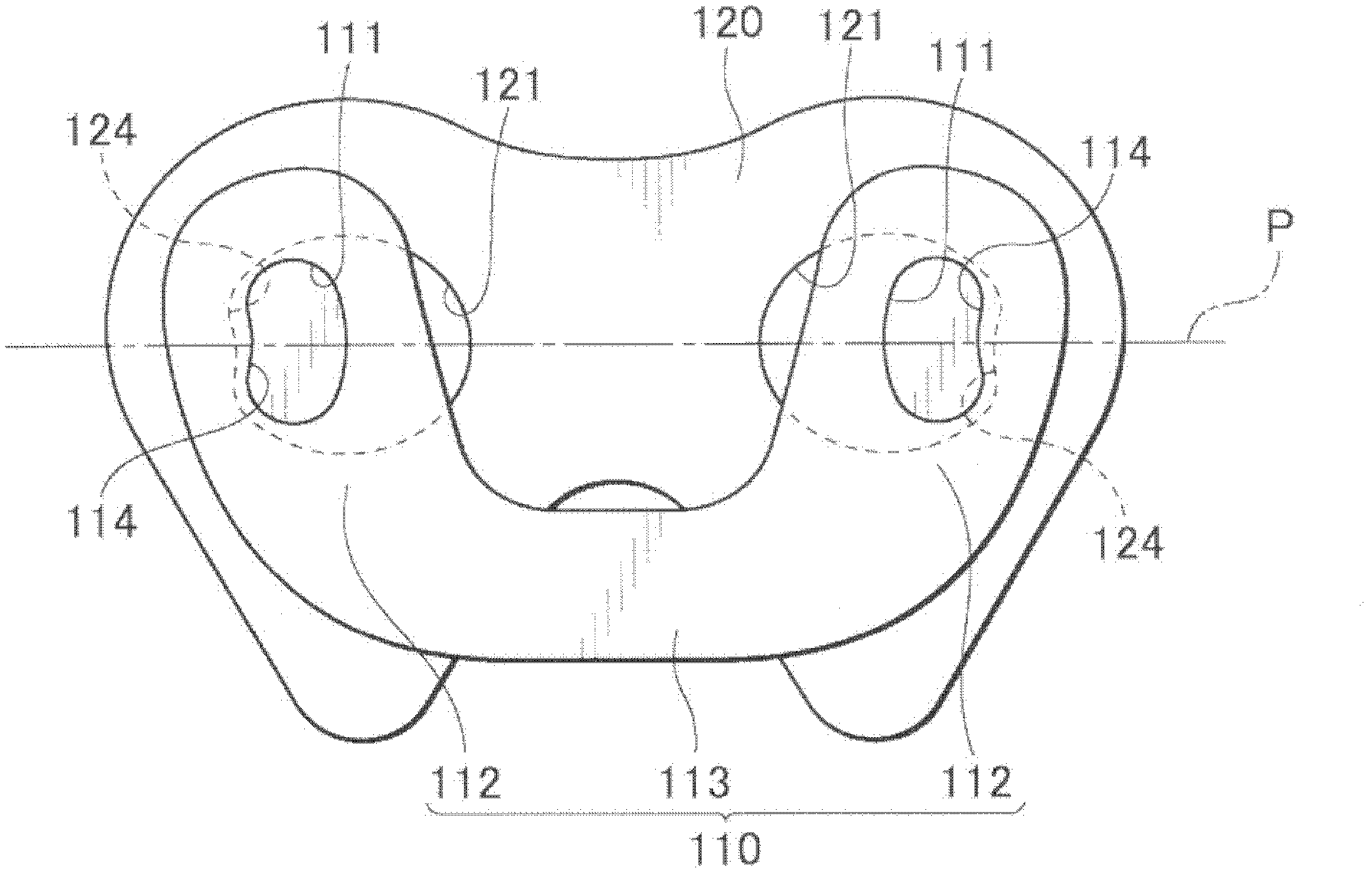

[0050] Such as figure 1 , figure 2 As shown, the silent chain 100 that adopts the guide plate 110 of an embodiment of the present invention has the following structure: each of the guide chain link rows has a pair of teeth and the middle link plate 120 of the connecting pin hole and the non-guide chain link row. The inner chain plates 130 are stacked alternately, and at the same time, a pair of long locking pins 141 and short locking pins 142 with long and short lock faces are provided, so that the locking faces are opposed to the connecting pin holes of the middle chain plates 120 and the inner chain plates 130, The intermediate link plates 120 and the inner link plates 130 are rotatably connected by being inserted into the connecting pin holes. Furthermore, the guide plates 110 are disposed on the outermost sides of the intermediate link plates 120 of the guide link ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com