Truck for removing sludge from inspection well

A technology for silt and manholes, which is applied in waterway systems, water supply devices, buildings, etc., can solve the problems of short continuous operation time, cumbersome operation, and difficulty in unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

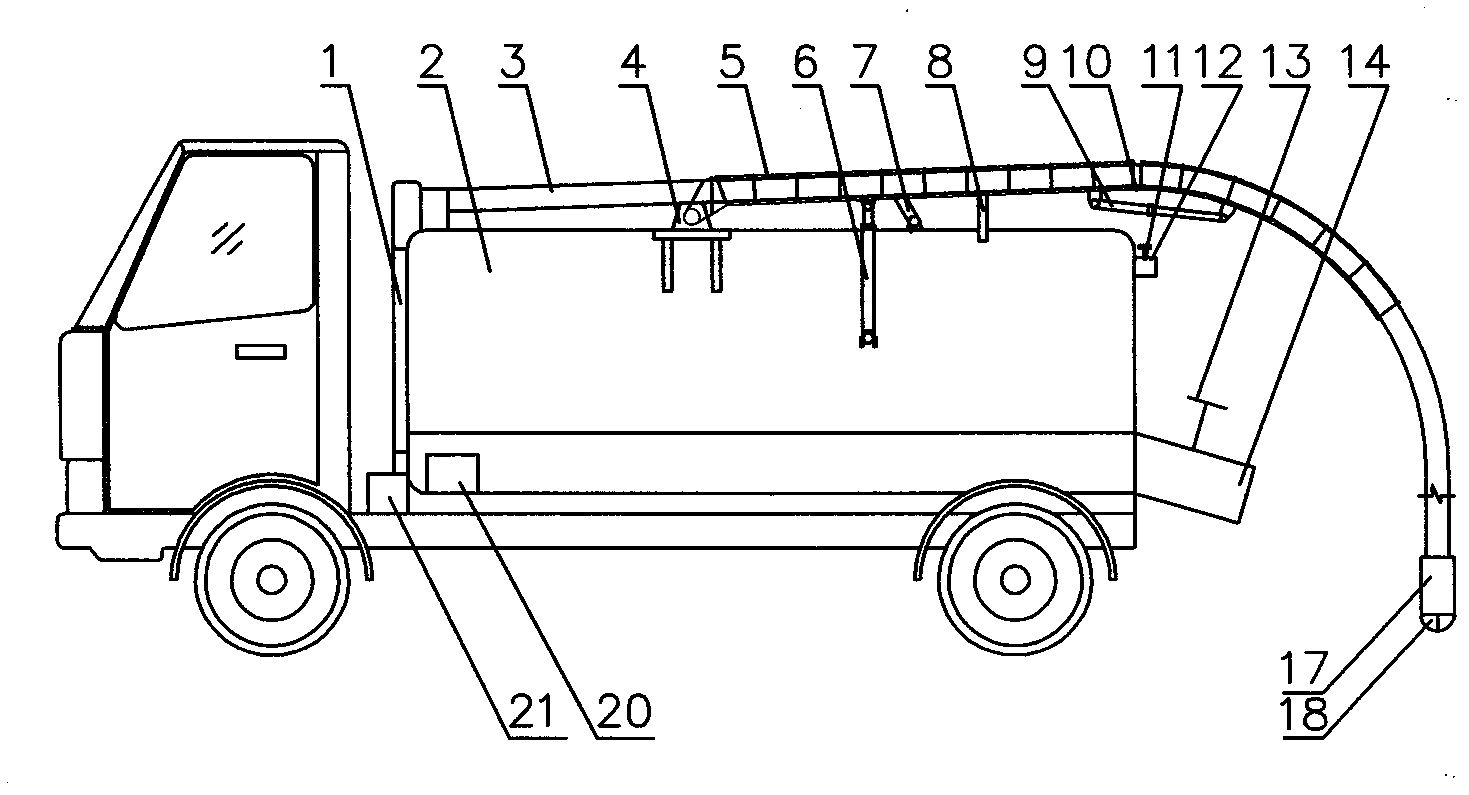

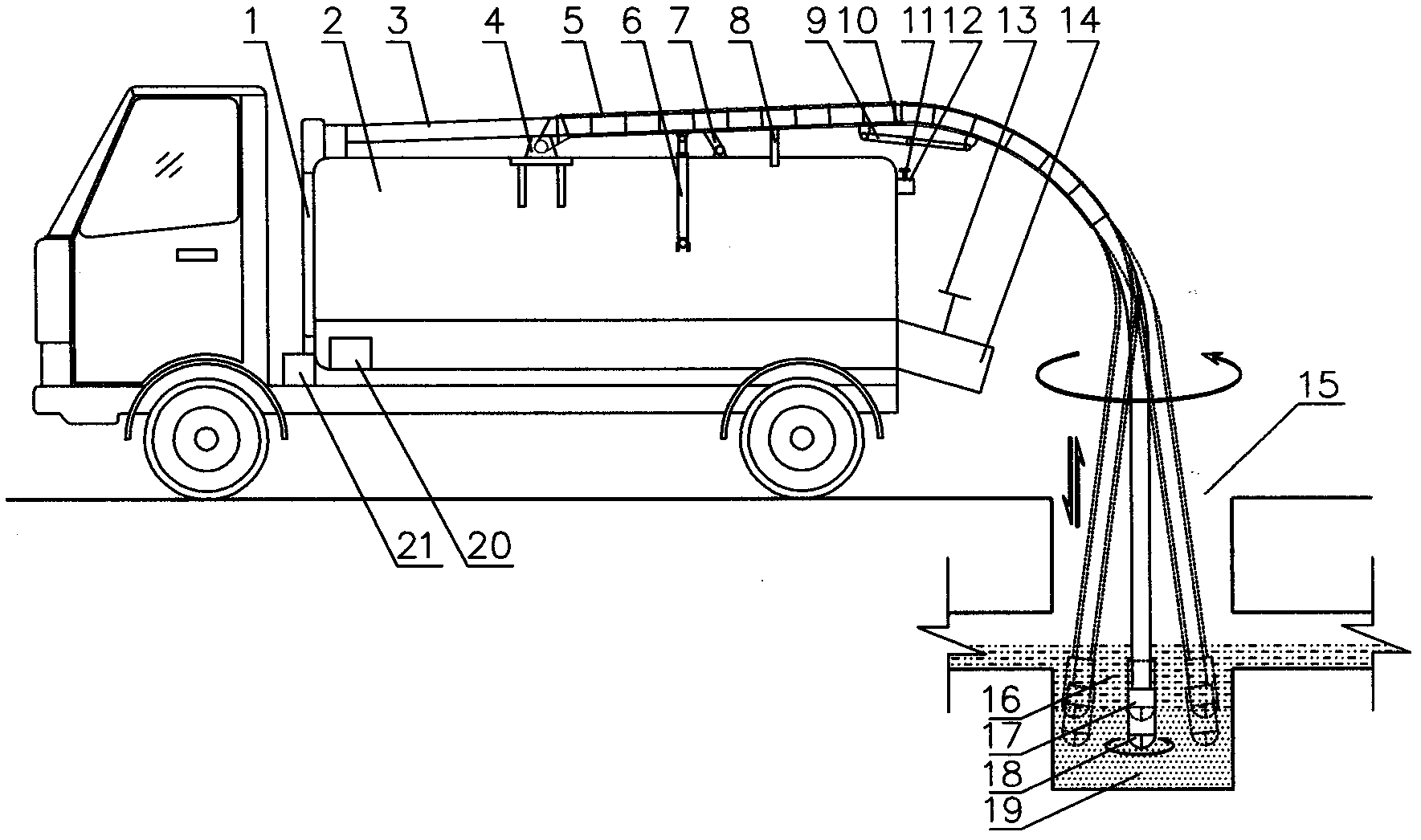

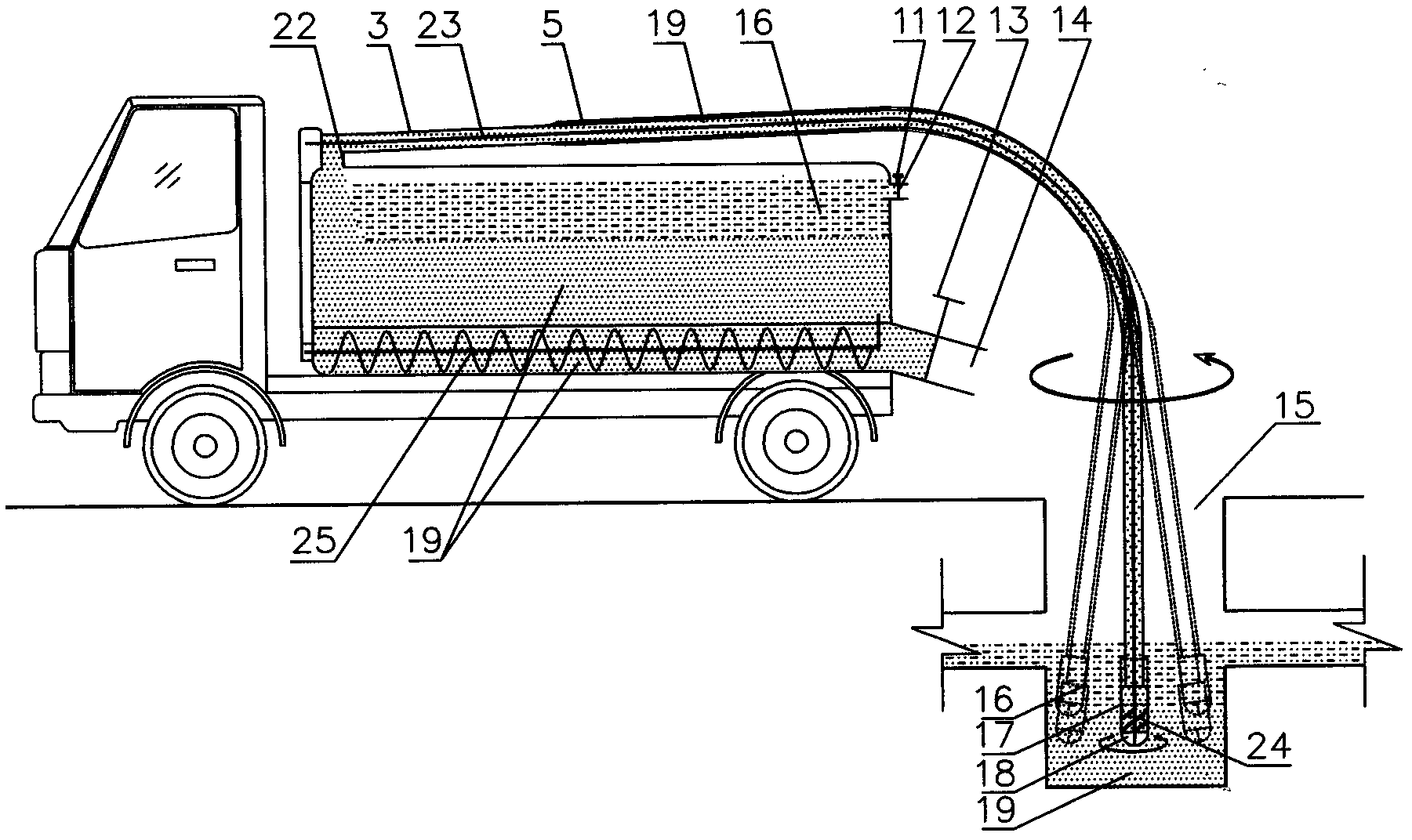

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, by 20 microcomputer controllers, start the vehicle power, and connect the vehicle power unit through 1, open 21 oil pumps and 23 drive flexible shafts. At the same time, 20 microcomputer controllers drive 6 mud hoses to move up and down, 7 mud hoses to move left and right, 9 mud hoses to move back and forth, and 3 mud hoses and 5 mud hose supports to move from 8 The mud hose bracket shelf is removed. 23 flexible shafts, 3 mud hoses, 17 mud pumps, and 18 mixing heads are correctly sent into the 15 inspection wells. According to the size of 15 inspection wells, select the program that 20 microcomputer controllers have set. Under the control of the program, in a spiral form from top to bottom, use 18 stirring heads to stir the 19 sludge deposited in 15 inspection wells to make it flow. Mud hose and 22 mud storage tanks enter the mud inlet, input in 2 mud storage tanks. After continuous operation and 19 si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com