Aluminum coil storage device and application method thereof

An aluminum coil and material storage technology is applied in the field of aluminum coil material storage devices, which can solve the problems of low production efficiency, high product wear, and high energy consumption, and achieve the goal of improving production efficiency, reducing production costs and saving energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

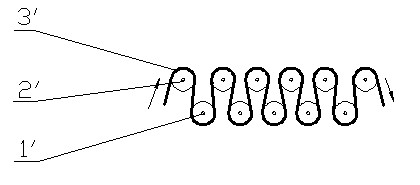

[0020] Such as figure 1 As shown, it is a structural schematic diagram of the storage device for aluminum coils in the prior art. When threading the belt, it passes through the fixed roller 2' and the floating roller 1' sequentially along the direction of the arrow. The aluminum strip 3' used for the band is tens of meters long, so it needs a lot of force to complete the threading process, and the operation is complicated and time consuming. During stable production, the fixed roll 2' and the floating roll 1' rotate together, which consumes a lot of energy, and the production cost is high, and the surface wear of the aluminum strip 3' is also more.

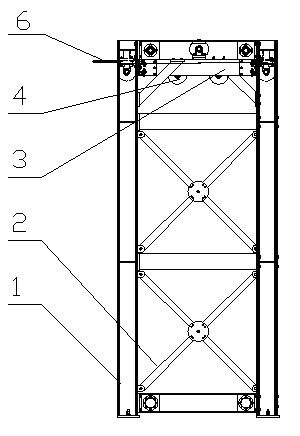

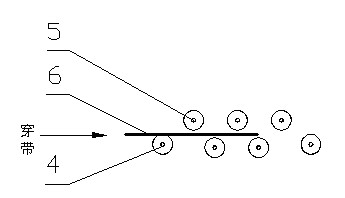

[0021] Such as figure 2 and image 3 As shown, the storage device for aluminum coils includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com