Anti-rotation structure for stop valve

A technology of anti-rotation structure and stop valve, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems of affecting the service life of valve stem packing seal valve disc, damage, increasing cost, etc., so as to achieve simple and reasonable structure and ensure valve The effect of using and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Hereinafter, the present invention will be more clearly and completely described with reference to a preferred embodiment and in conjunction with the accompanying drawings.

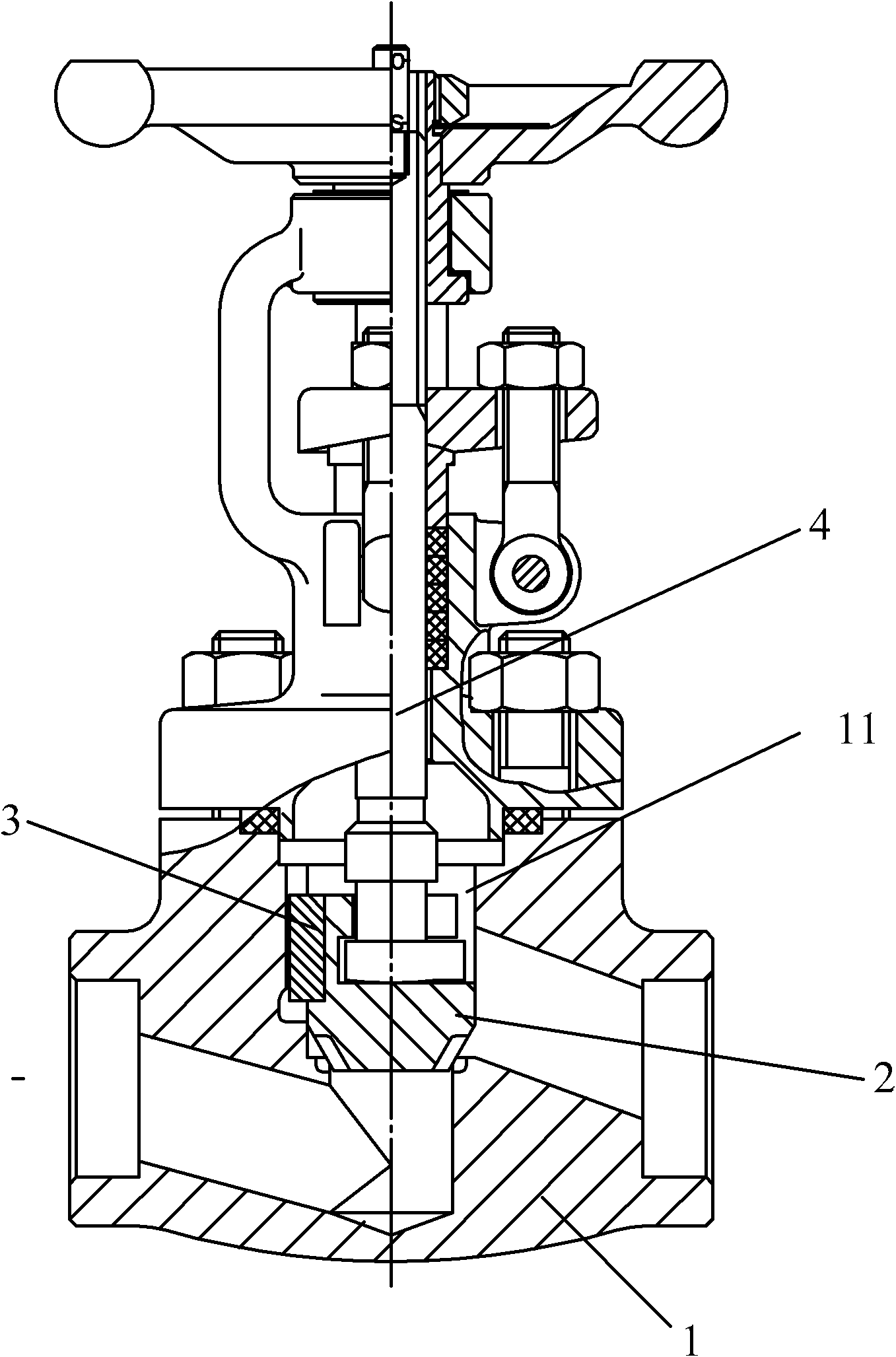

[0010] like figure 1 and figure 2 As shown, the anti-rotation structure of the globe valve of the present invention includes a valve body 1, a valve disc 2, a key 3, and a valve stem 4, the valve body 1 has a valve cavity 11, the key 3 is fixed on the valve disc 2, the valve disc 2 and the key 3 The valve flap assembly is composed, the valve flap 2 and the key 3 are installed in the valve cavity 11 of the valve body 1, wherein the key 3 abuts against the inner cavity groove of the valve body 1 to limit the rotation of the valve flap 2 in the valve cavity 11, and there are up and down Movement orientation.

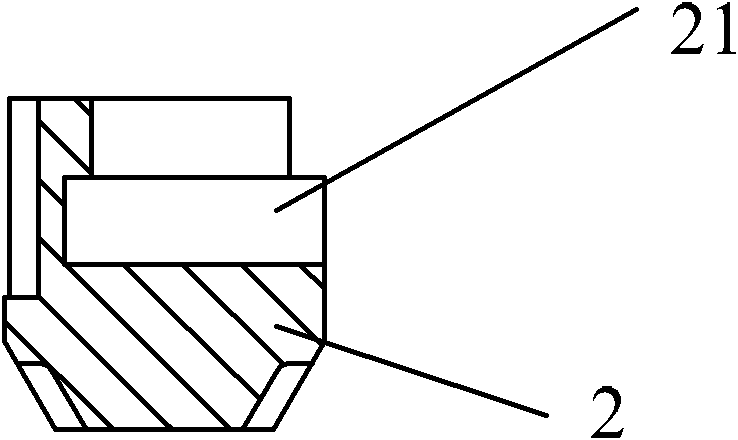

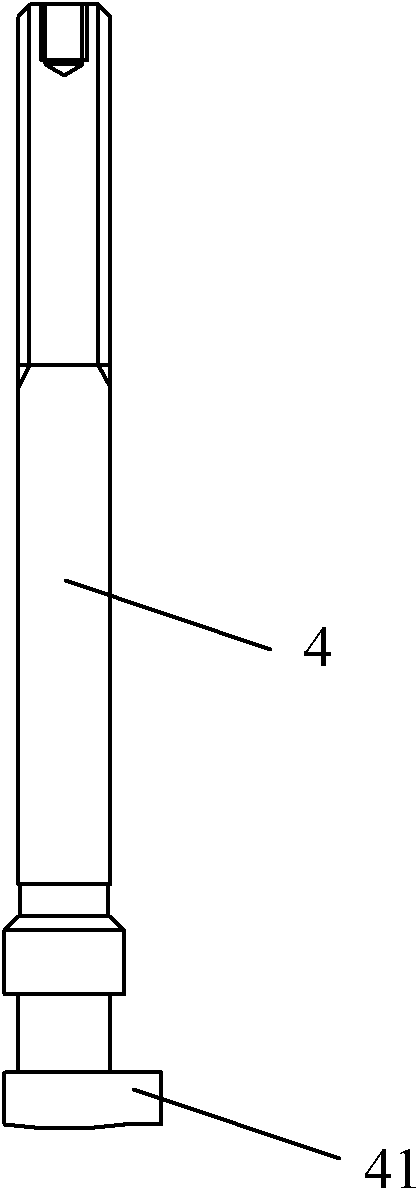

[0011] like figure 2 As shown, the valve flap 2 has a T-slot 21 . like image 3 As shown, the valve stem 4 has a T-shaped head 41, the T-shaped head 41 is installed in the T-shaped groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com