Tool wagon for assembling and disassembling chuck of coiler

A technology of tool trolley and winding machine, which is applied in the field of winding machine chuck disassembly and assembly tool trolley, which can solve the problems of low work efficiency, unsafety, and injury to operators, and achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

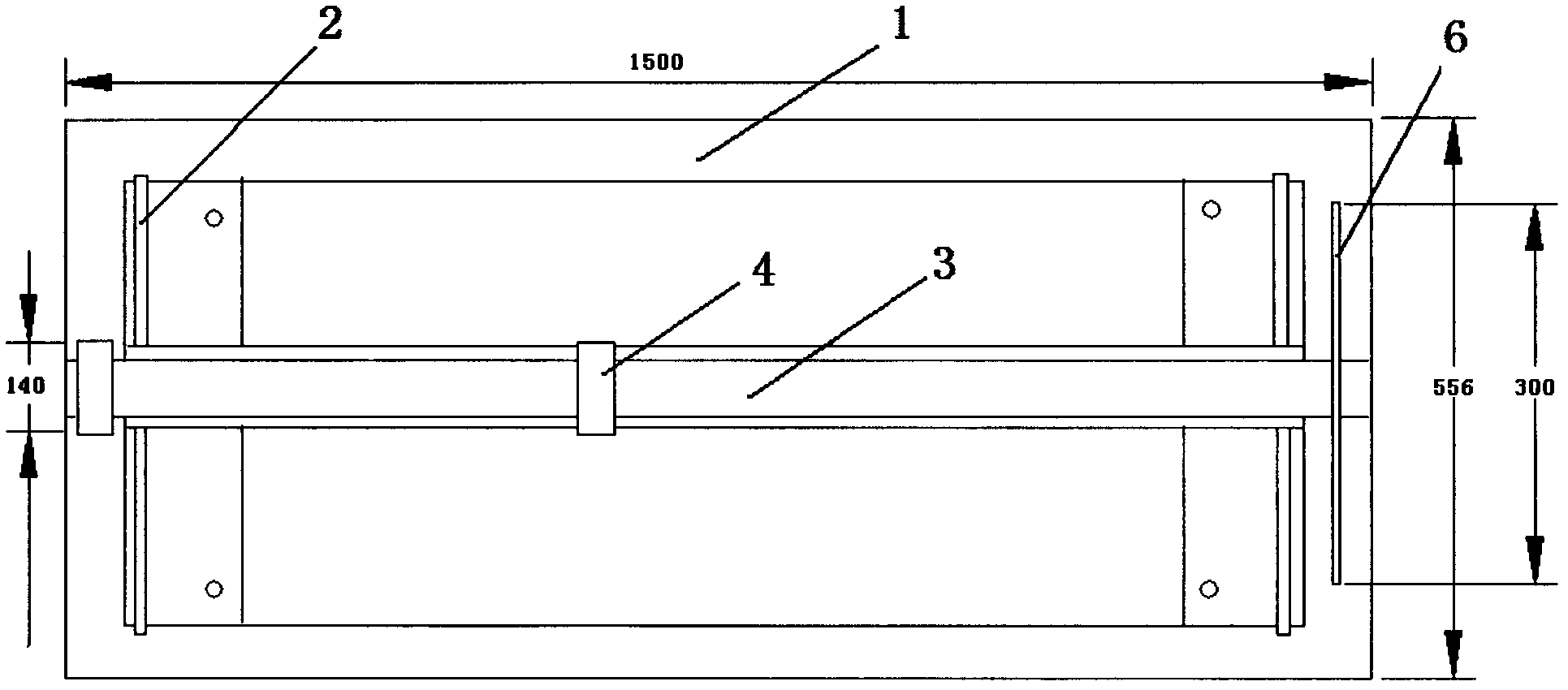

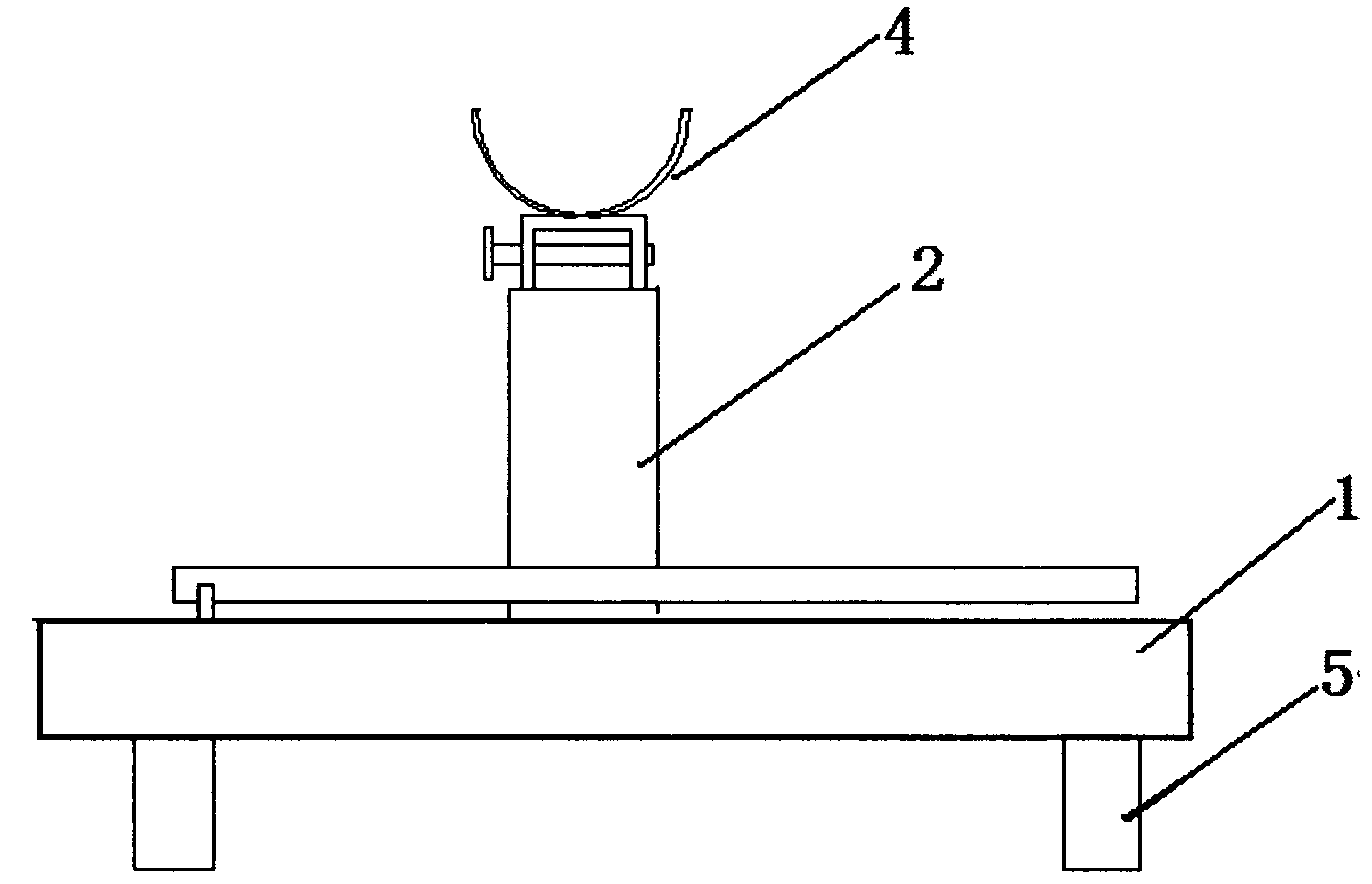

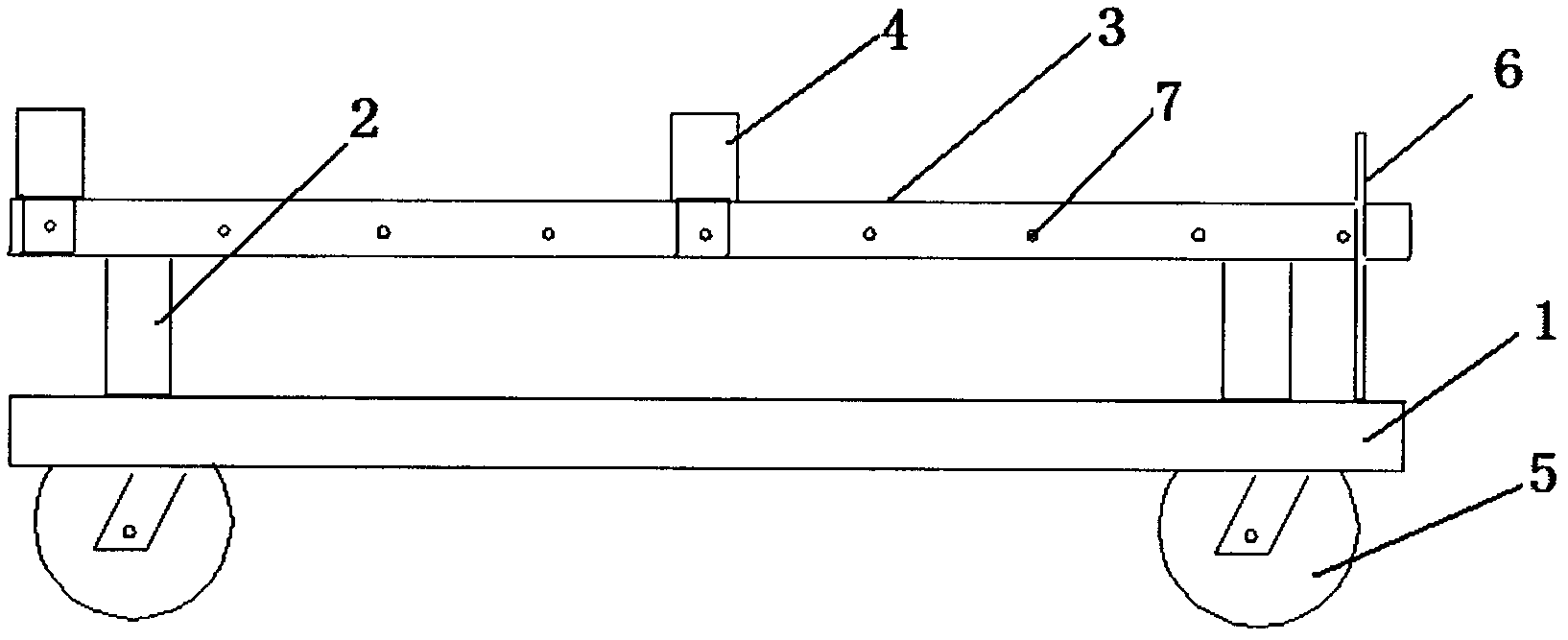

[0020] After a period of operation, the chuck of the ACW4T-1500 / 10 winding machine needs to be cleaned and maintained. Push the tool trolley of the present invention to the maintenance room using the handle 6, put it next to the winding machine, and adjust the height of the cross bar 3 through the hydraulic jack 2, so that the operator can easily disassemble the chuck for cleaning and maintenance. After determining the height, adjust The support groove on the crossbar. The crossbar is a U-shaped channel steel with a width of 65mm and a length of 1500mm. There are 9 screw holes with a diameter of 10mm evenly distributed on it. The center of the first screw hole is 80mm from the top and 15mm from the upper surface of the crossbar. , the distance between the second screw hole and the first screw hole is 165mm, and the distances between the second, third, fourth, fifth, sixth, seventh, eighth and ninth are all It is 165mm. The support groove is composed of a U-shaped channel steel...

Embodiment 2

[0022] After a period of operation, the chuck of the ACW5T-1380 / 12 winding machine needs to be cleaned and maintained. Push the tool trolley of the present invention to the maintenance room using the handle 6, put it next to the winding machine, and adjust the height of the cross bar 3 through the hydraulic jack 2, so that the operator can easily disassemble the chuck for cleaning and maintenance. After determining the height, adjust The support groove on the crossbar. The crossbar is a U-shaped channel steel with a width of 65mm and a length of 1500mm. There are 9 screw holes with a diameter of 10mm evenly distributed on it. The center of the first screw hole is 80mm from the top and 15mm from the upper surface of the crossbar. , the distance between the second screw hole and the first screw hole is 165mm, and the distances between the second, third, fourth, fifth, sixth, seventh, eighth and ninth are all It is 165mm. The support groove is composed of a U-shaped channel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com