Hair comb capable of removing hooked hair

A hair and crochet technology, applied in the field of hair combs, can solve the problems of high height of hair combs, inability to achieve miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

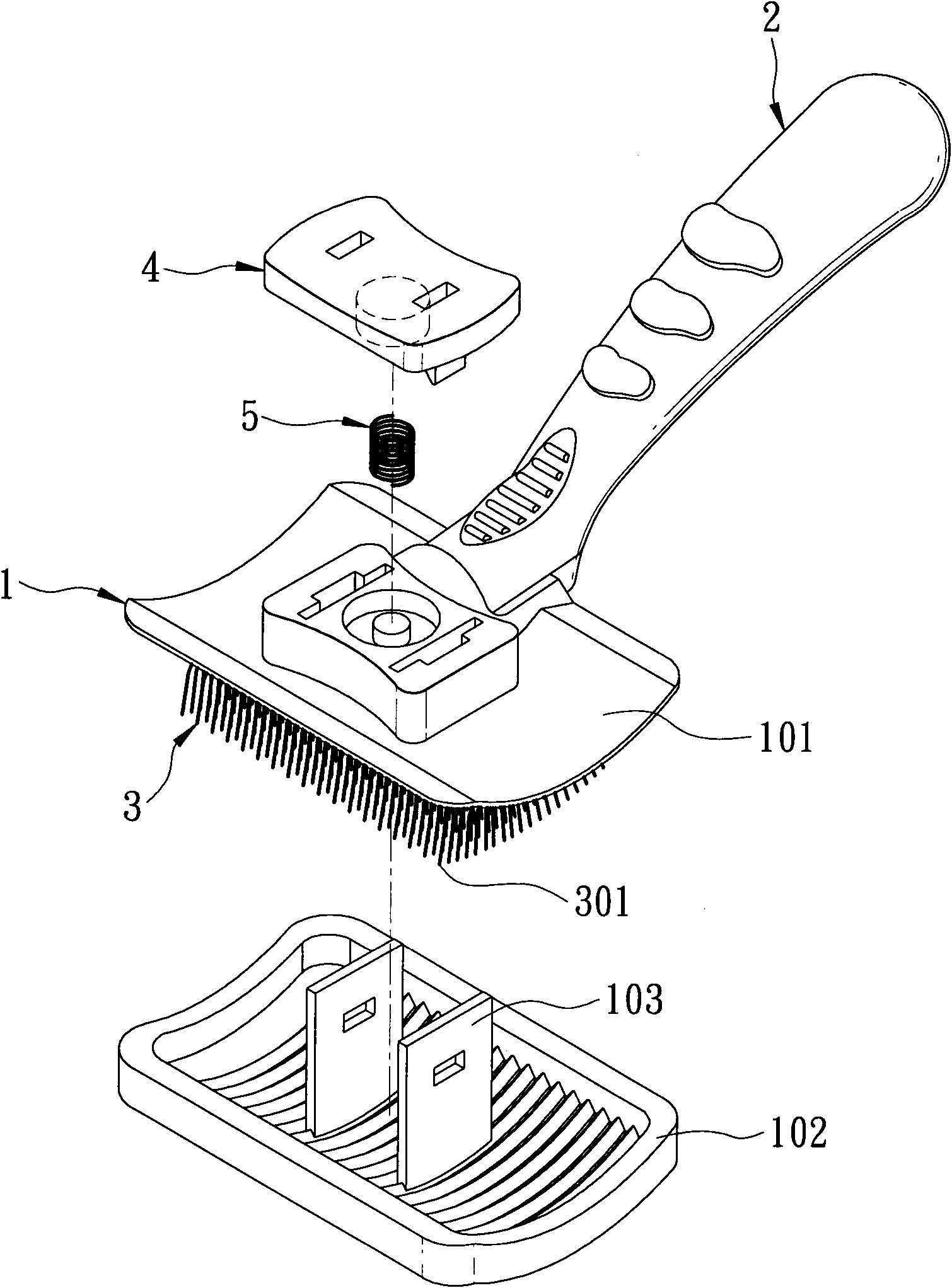

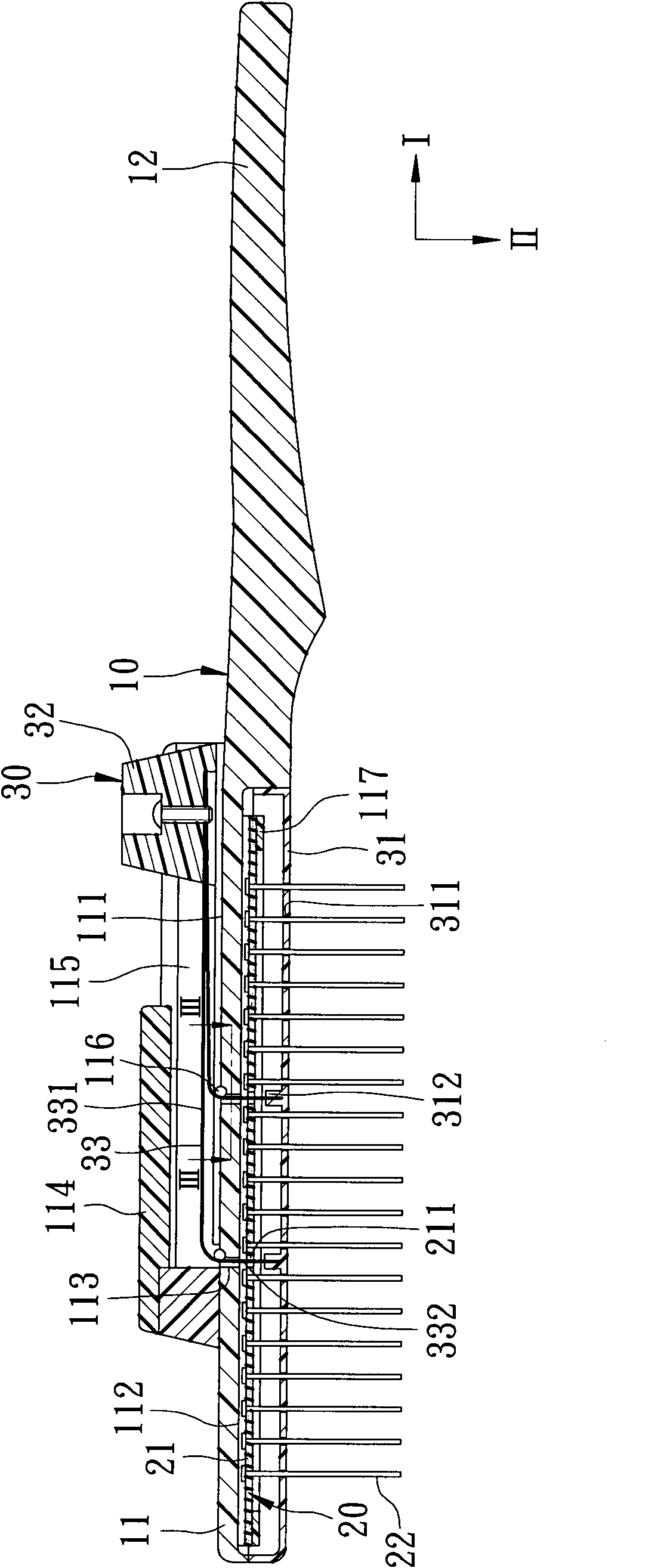

[0025] like figure 2 and Figure 4 As shown, the first preferred embodiment of the hair comb for removing snags of the present invention includes a body 10 , a comb unit 20 and a detent unit 30 .

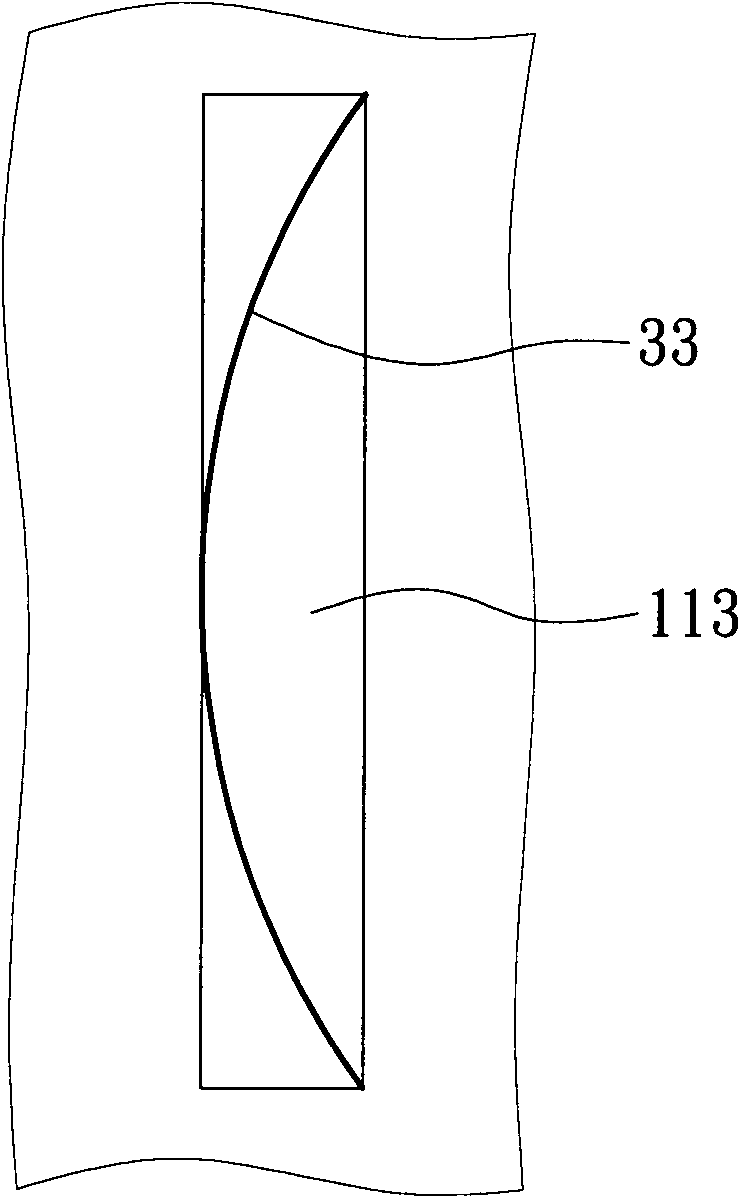

[0026] The body 10 extends along a first direction I, and has a comb base 11 and a handle 12 extending along the first direction I and connected to the comb base 11 . The comb base 11 has a top surface 111, a bottom surface 112 opposite to the top surface 111, two through holes 113 passing through the top surface 111 and the bottom surface 112, and a hollow boss 114 protruding from the top surface 111. and a guide portion 115 approaching the top surface 111 and extending along the first direction I, the through hole 113 is rectangular (see image 3 ), the guiding portion 115 is in the shape of a groove, and is disposed in the boss 114 . In addition, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com