Photoreceptive drum connection assembly

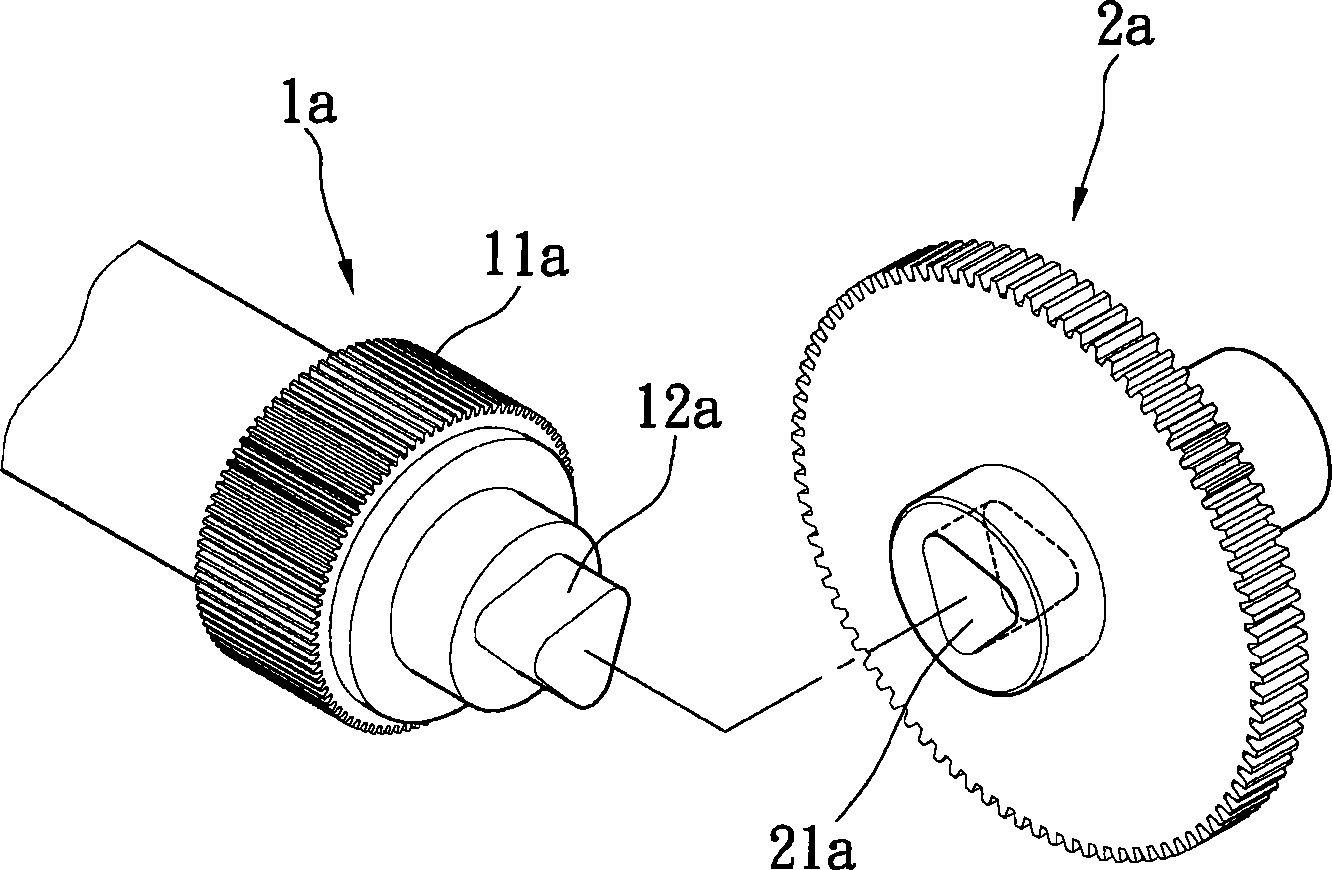

A technology for connecting components and photosensitive drums, applied in optics, electrical recording, instruments, etc., can solve the problem of damage to the drum gear 11a or triangular columnar bump 12a, etc., to save maintenance costs, fast assembly, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

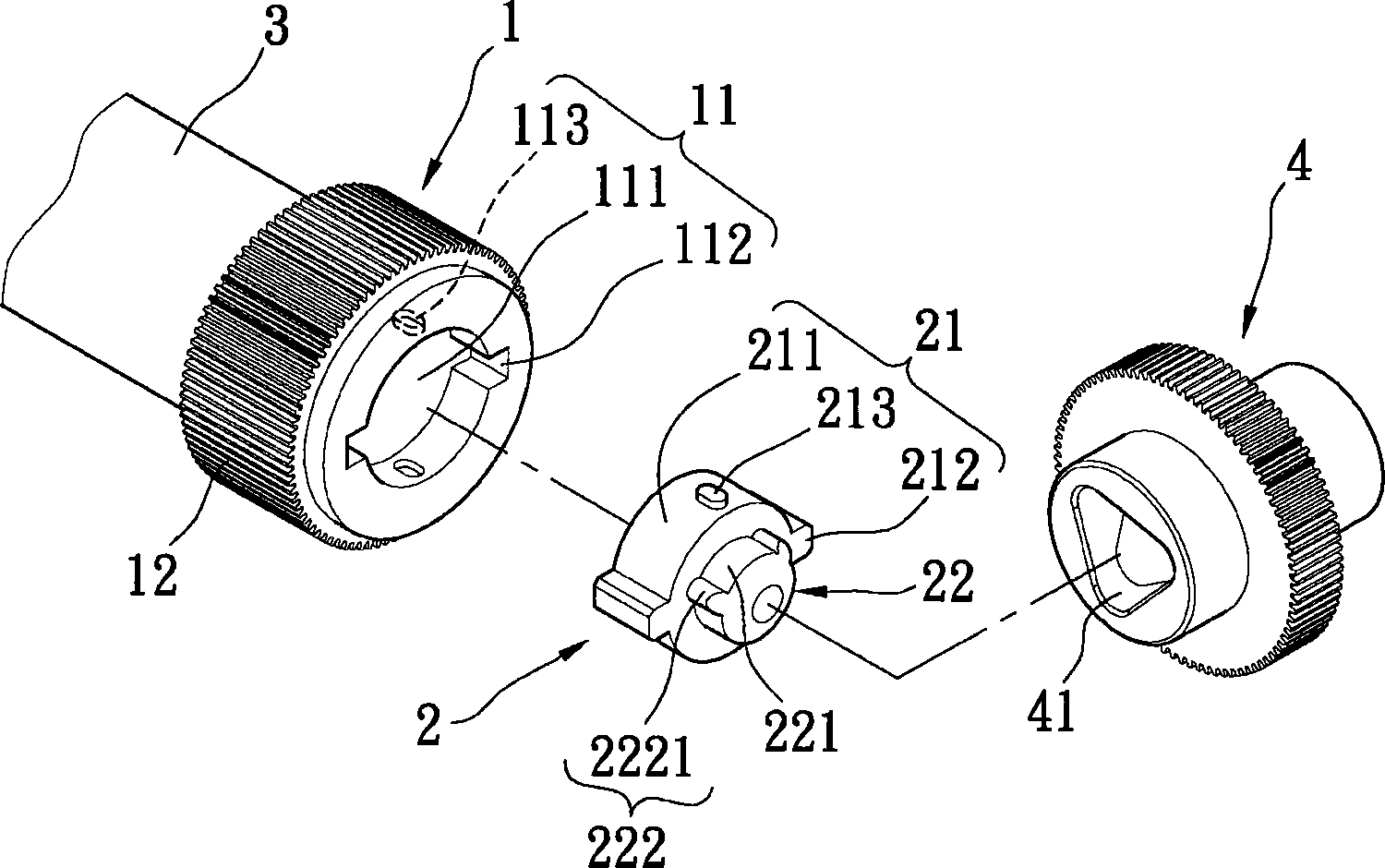

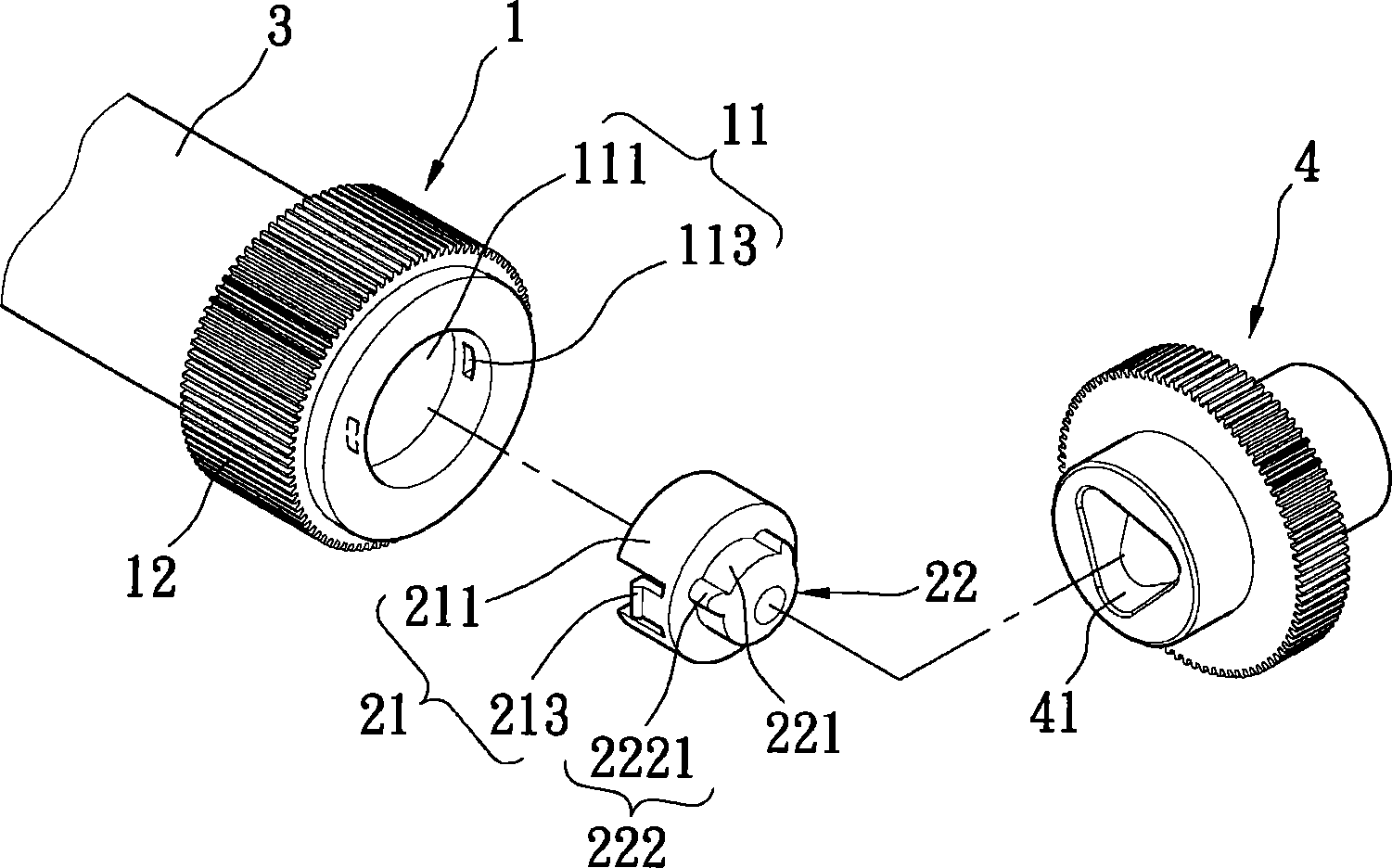

[0055] see Figure 2 to Figure 4 , which is the first embodiment of the present invention, the present invention is a photosensitive drum connection assembly, including: a drum gear 1 and a connector 2 detachably connected to one end of the drum gear 1, the other end of the drum gear 1 is connected to On a photosensitive drum 3 , the connector 2 is connected to a drive shaft 4 . Wherein, the drum gear 1 is detachably connected to the photosensitive drum 3 , or the drum gear 1 and the photosensitive drum 3 are integrally formed.

[0056] The drum gear 1 has a first connecting portion 11 and a ring gear 12 connected to the first connecting portion 11 . The first connecting part 11 is arranged on one end of the drum gear 1, and the first connecting part 11 has a groove 111, and the groove 111 is formed by inwardly recessing one end of the first connecting part 11; the ring gear 12 is arranged on On the other end of the drum gear 1 , the ring gear 12 is sleeved and fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com