Hydraulic loss testing platform and testing method of canned motor rotor system

A technology for shielding motors and hydraulic loss, applied in the mechanical field, can solve the problems of total power loss of motors, limited quantitative relations, inconvenience, etc., and achieve the effect of solving shielding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

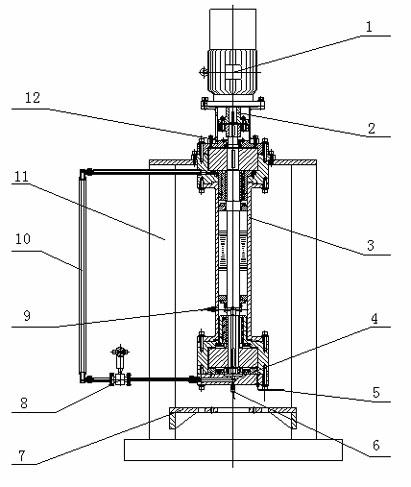

[0043] Such as figure 1 As shown, this embodiment provides a shielded motor rotor system hydraulic loss test platform, including a frequency conversion motor 1, a coupling 2, a shielded motor 3, a static pressure tube 4, a Pitot tube flowmeter 5, a first pressure sensor 6, Motor tray 7, electromagnetic flowmeter 8, second pressure sensor 9, circulation pipeline 10, support frame 11 and sealing ring 12; described variable frequency motor 1 and shielded motor 3 are connected by coupling 2, described shielded motor 3 and A sealing ring 12 is provided between the couplings 2, a second pressure sensor 9 is provided in the middle of the shielded motor 3, a static pressure tube 4 and a first pressure sensor 6 are provided below the shielded motor 3, and the shielded motor 3 Supported by a support frame 11, the motor tray 7 is arranged on the support frame 11. The Pitot tube flowmeter 5 and the electromagnetic flowmeter 8 are located under the shielded motor 3 and communicate with the...

Embodiment 2

[0051] This embodiment provides a method for testing hydraulic loss of a rotor system of a shielded motor. The shielded motor involved in this embodiment has a flywheel and an auxiliary impeller structure. During the rotation process, the hydraulic loss of the shielded motor is divided into two parts: the rotor pressure flow power loss and the rotor shear flow power loss. However, these two power losses are often mixed with other losses such as water lubricated bearing power loss and motor shielding loss, and are expressed in the form of total power loss of the shielded motor. The proportion of pressure flow power loss and shear flow power loss in the total loss can only be obtained by calculation, and there is a lack of experimental data.

[0052] The test method of this embodiment comprises the following steps:

[0053] The first step is to start the variable frequency motor 1, and the variable frequency motor 1 drives the shielded motor 3 through the coupling 2, and the ro...

Embodiment 3

[0059] This embodiment provides a method for power separation of the shielded motor 3 in Embodiment 2:

[0060] (1) Collect the working parameters of the variable frequency motor 1, and calculate the power of the shielded motor 3 through the voltage, current, power factor of the variable frequency motor 1 and the efficiency of the variable frequency motor 1. The calculation formula is as follows:

[0061]

[0062] in: Simplify the total power loss of shielded motor 3 for the input, Indicates the voltage input to the variable frequency motor, Indicates the current input to the variable frequency motor, Indicates the power factor of the variable frequency motor, Indicates the efficiency of the variable frequency motor.

[0063] (2) Collect the reading difference of pressure sensors 6 and 9 , to obtain the local high pressure generated by the auxiliary impeller 15;

[0064] is the indication of the first pressure sensor 6 and the second pressure sensor 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com