Device of testing horizontal fog scale distribution and method thereof

A technology of distribution testing and fog volume, applied in the direction of measuring devices, testing of machine/structural components, instruments, etc., can solve the problem of not being able to fully reflect the distribution of fog droplets, reduce the workload of calibration, save hardware costs, The effect of fast automatic drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

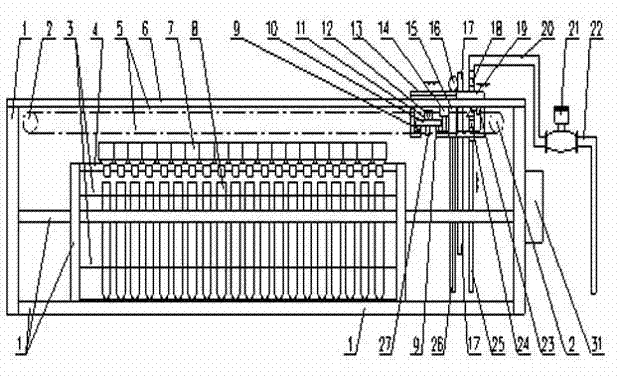

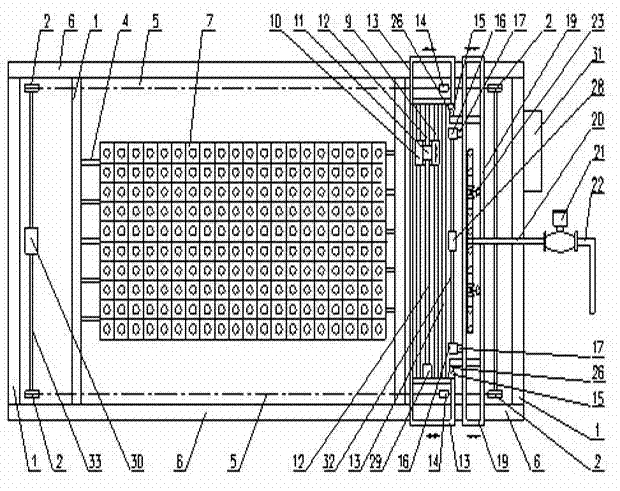

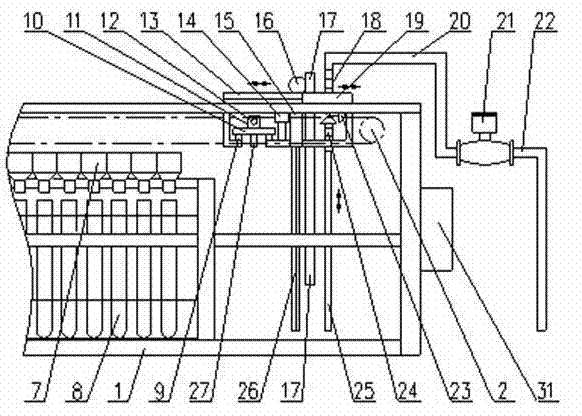

[0022] Such as Figure 1-4 As shown, the horizontal fog distribution test device is mainly composed of a horizontal fog box array 7, a liquid collection unit array 8, a non-contact automatic inspection system for liquid collection, a partitioned liquid suction automatic drainage system, a control system 31 and a frame 1 and other components. The horizontal fog-collecting box array 7 divides the droplet deposition area according to two-dimensional grids, collects the deposited fog droplets in each grid, and guides them into the corresponding liquid-collecting units in the liquid-collecting unit array 8 . The non-contact liquid collection volume automatic inspection system is equipped with a plane coordinate shifting mechanism and a non-contact liquid level detection device 27, which can realize the liquid collection unit array 8 automatic inspection of the liquid collection volume. A vacuum pump 21 and a main branch suction pipeline are provided in the partition suction type a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com