Nondestructive detection method for early damage of ferromagnetic material

A non-destructive testing and ferromagnetic material technology, applied in the field of measurement, can solve problems such as lack of material damage detection and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The magnetic non-destructive detection method of the early damage of ferromagnetic materials, taking the detection of Q235 steel plate as an example, the present invention is further described, and the detection includes the following steps:

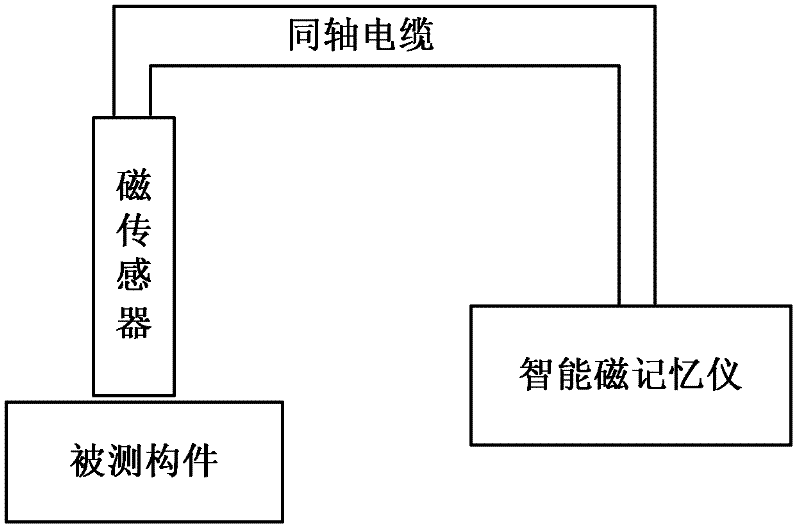

[0020] steps as figure 1 As shown, the magnetic sensor is connected to the intelligent magnetic memory instrument through a coaxial cable, and the surface of the Q235 steel plate is detected every 0.2 mm by the magnetic sensor, and the tangential magnetic flux leakage amplitude and the normal magnetic flux leakage amplitude of the measured surface are obtained. And stored in the intelligent magnetic memory device;

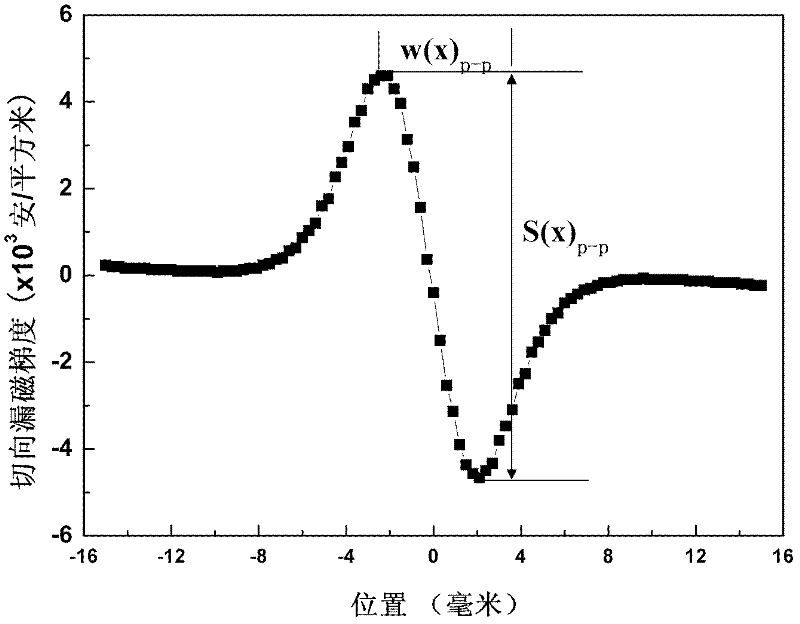

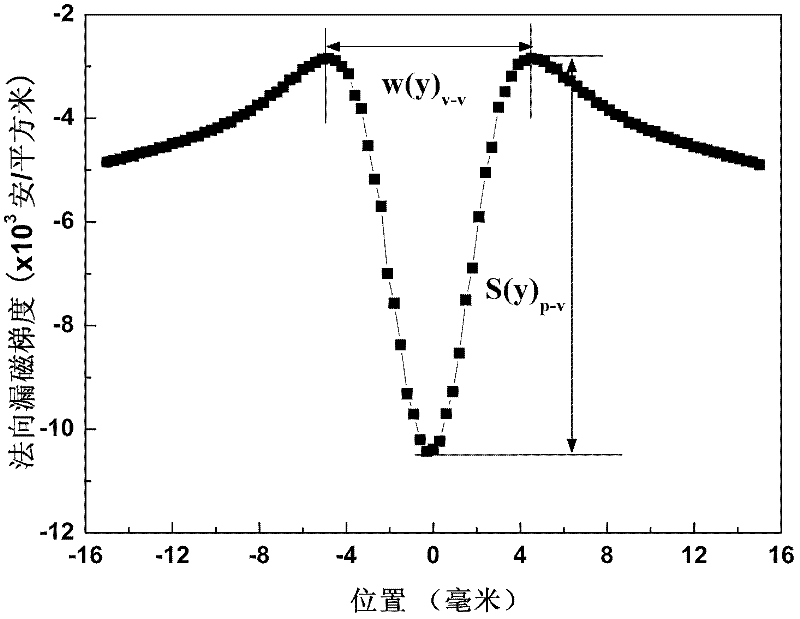

[0021] Step 2 Calculate the tangential magnetic flux leakage gradient value and the magnetic flux leakage normal gradient value of the measured surface according to the tangential magnetic flux leakage amplitude and normal magnetic flux leakage amplitude of the measured surface, and the results are as follows figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com