Measuring device and measuring method for well-cementing annular weight loss of cement slurry

A measuring device and cement slurry technology, which are applied in the directions of surveying, earth-moving drilling, wellbore/well components, etc., can solve the problems of lack of pertinence in measures and insignificant anti-channeling effect, so as to solve the problem of underground temperature change and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

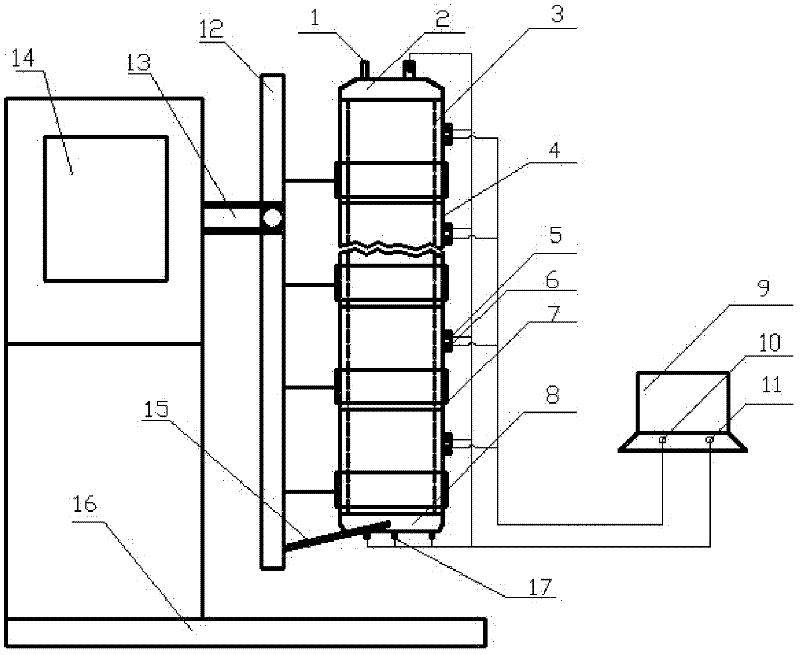

[0026] Further illustrate the present invention according to accompanying drawing and embodiment below.

[0027] see figure 1 , the cementing annular cement slurry weight loss measurement device, mainly composed of a base 16, a control panel 14, a vertical pillar 12, a slurry cylinder, and a computer 9, is characterized in that the measuring device is located on the base, and the vertical pillar is supported by The shaft 15 is connected with the slurry cylinder, and is connected with the control panel through the rotating shaft 13, which can realize the rotation from 0° to 90°; the slurry cylinder has a pressure hole 1, an inner cylinder 3, an outer cylinder 4 and an inner cylinder and an outer cylinder The annulus between the slurry cylinders is combined in sections, and each section has a temperature sensor 5, a pressure sensor 6 and a heating and cooling jacket 7. The slurry cylinder has an upper top cover 2 and a lower bottom cover 8. The slurry cylinder There are also th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com