Pressing-buckling lock catch plate and buckling method thereof

A snap-fit, panel technology, applied in the direction of floors, coverings/linings, buildings, etc., can solve problems such as construction inconvenience, and achieve the effect of significant progress and convenient assembly and combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The push-fit locking plate of the present invention has a rectangular shape and has a first plane as a surface, a second plane opposite to the first plane, and four sides, wherein at least two of the opposite sides are respectively formed with protrusions. Tenon and tenon.

[0072] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0073] First preferred embodiment:

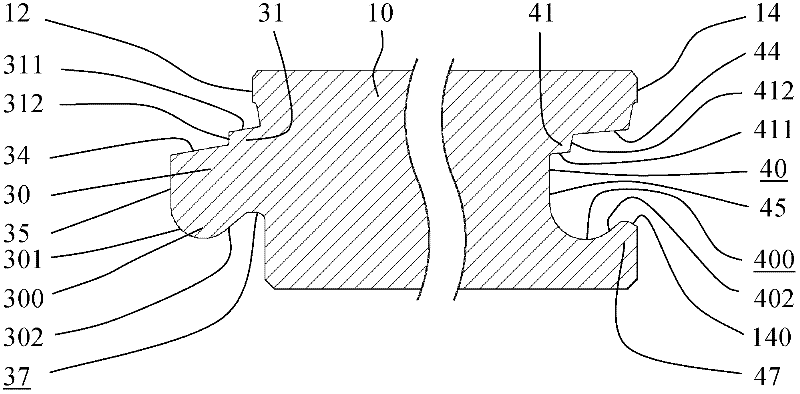

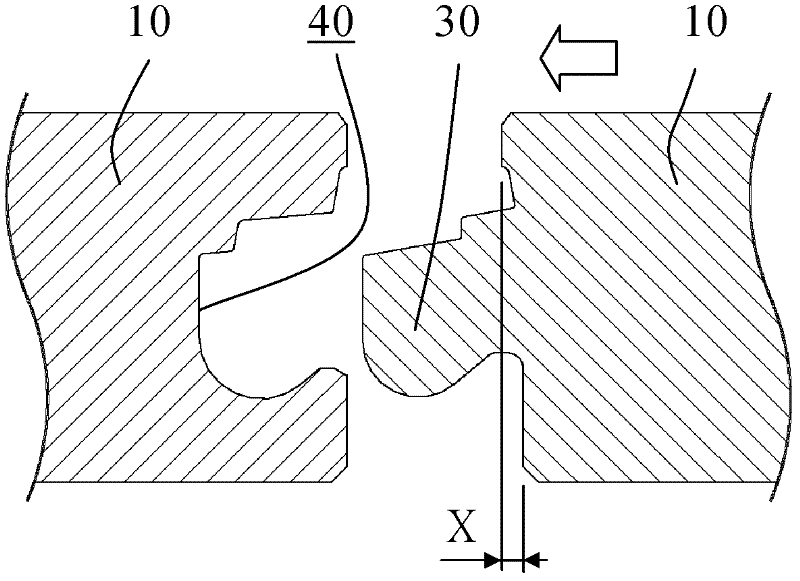

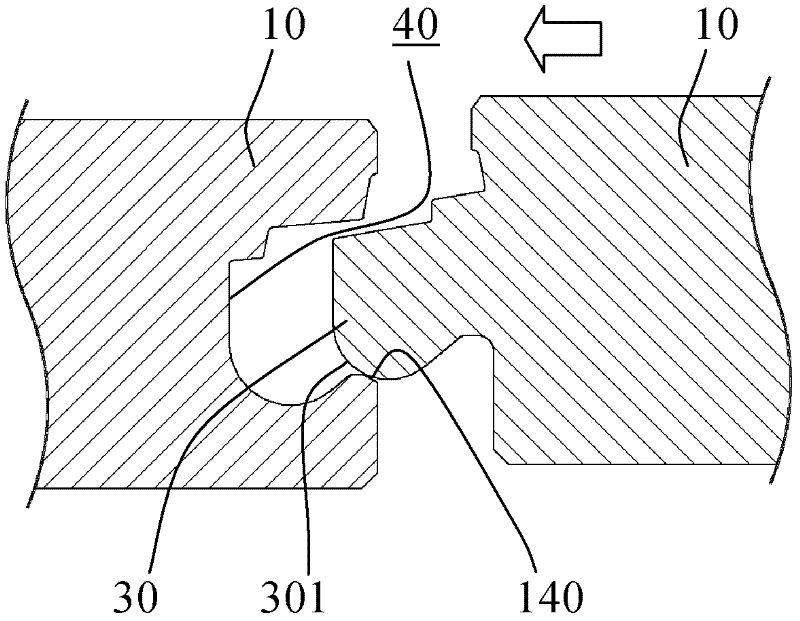

[0074] by figure 1As shown in the side view cross-sectional structural schematic diagram of the first preferred embodiment of the push-fit locking plate of the present invention, a tenon 30 protruding outward from the side 12 is formed on the side 12 of the plate unit 10. The tenon 30 has a top surface 34 and an outer side 35. A lower projection 300 is provided on the lower edge of the tenon 30. An outer slope 301 is formed outside the lower projection 300, and an inner slope 301 is formed inside the lower projection 300. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com