Automatic incasing machine for bottles

A technology for packing machines and bottles and cans, which is applied in packaging, packaging bottles, transportation packaging, etc., and can solve the problems of equipment cost, high maintenance cost, high input cost, and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

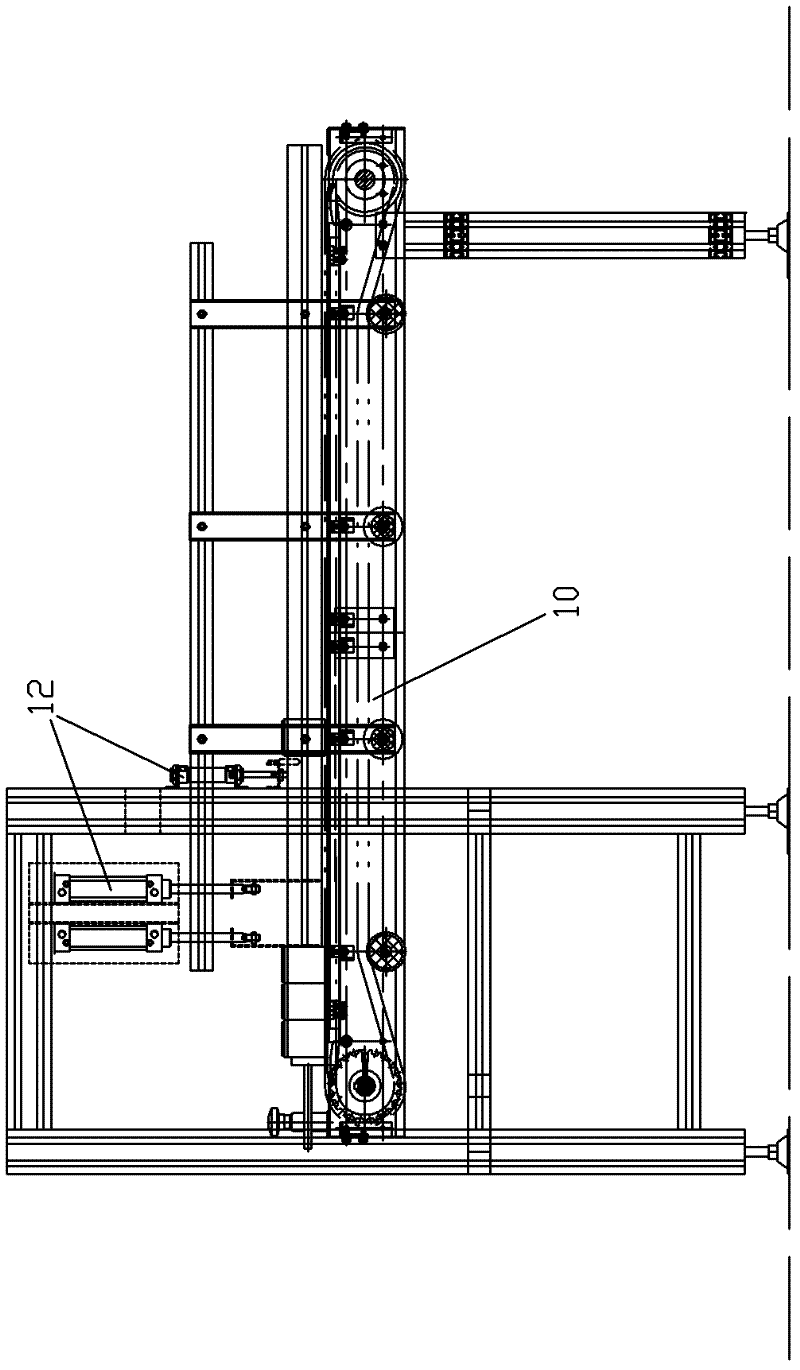

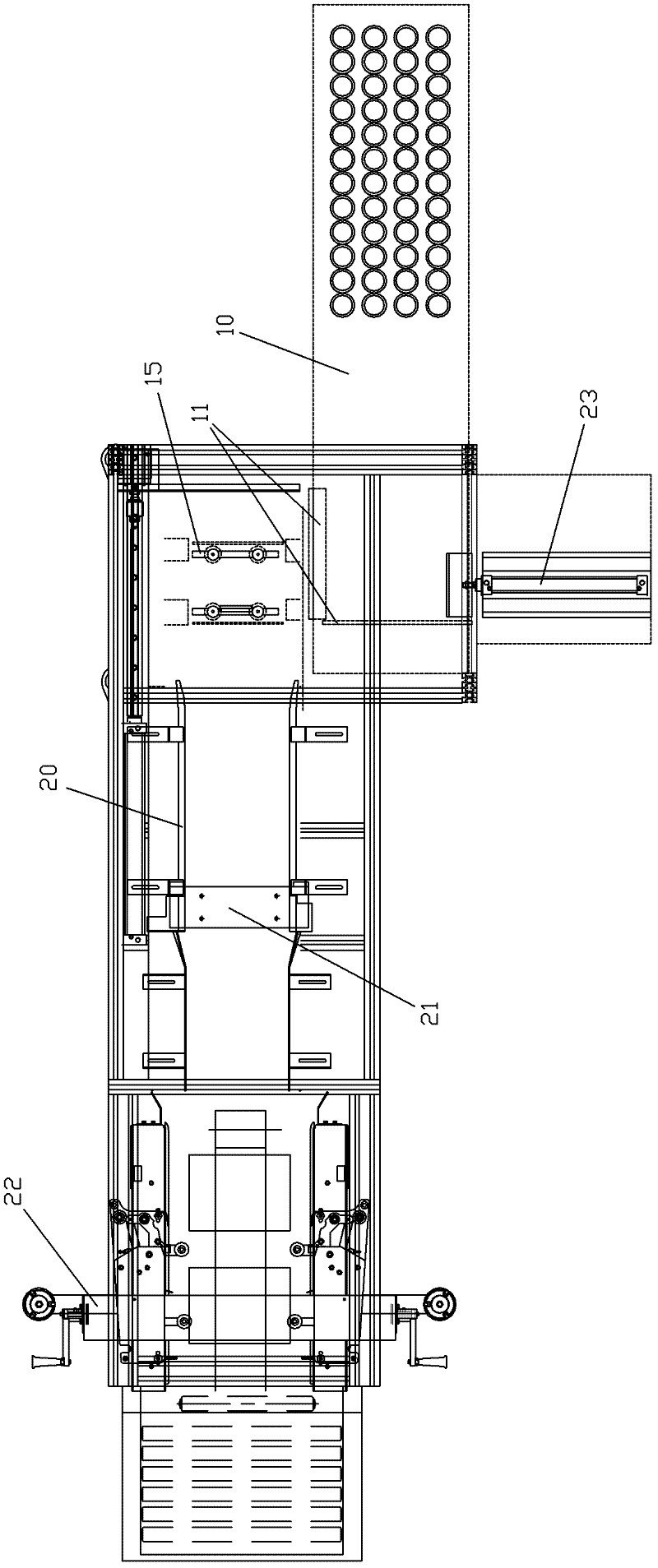

[0025] Reference figure 1 , figure 2 with image 3 , The automatic bottle filling machine of the present invention includes a motor-driven conveyor belt 10, a can blocking mechanism 11 and a canning arrangement mechanism 12 arranged behind the conveyor belt 10, a carton placing mechanism 13, an opening mechanism, and a push The tank mechanism 23, the free roller 16, the power roller 17, the box pushing mechanism 18, the closing mechanism, the double-sided roll tape packaging device 22, the frame, the PLC, the man-machine interface and the corresponding electronic detection device. The unpacking mechanism includes a vacuum suction cup system 14 and a box blocking mechanism 15. The vacuum suction cup system 14 and the box blocking mechanism 15 are both located below the carton placing mechanism 13; the lid closing mechanism is composed of a folding baffle for closing the left box lid 19. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com