Duplex skin-removing device and method for poultry paws

A dual-type, poultry claw technology, which is applied in poultry processing, slaughtering, food science, etc., can solve the problems of large losses for users, manual feeding and discharging, and non-continuous production, so as to reduce economic losses and improve production The effect of low efficiency and claw breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

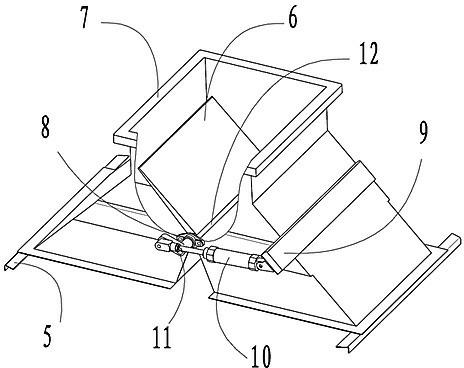

[0028] attached by figure 1 Shown: The poultry paw peeling equipment includes:

[0029] One frame I, two vertical claw removal devices II arranged side by side on the frame I, the feed distribution mechanism III arranged above the two vertical claw removal devices II, and the power mechanism IV arranged under the frame I , the programmable PLC control device Ⅴ that controls the vertical claw removal device Ⅱ and the feeding distribution mechanism Ⅲ.

[0030] attached by figure 1 As shown: the vertical claw removal device II includes a claw removal cylinder 1, an air-controlled automatic door 2 arranged on the outer wall of the claw removal cylinder 1, and a valve set at the center of the vertical claw removal cylinder 1 and connected to the power mechanism IV. The claw-removing turntable 3, a plurality of claw-removing glue fingers 4 arranged on the vertical claw-removing cylinder 1 and the claw-removing turntable 3.

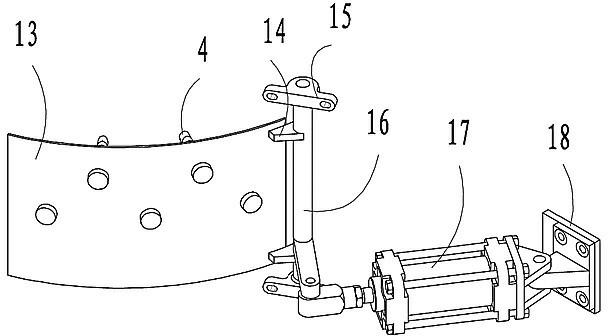

[0031] attached by figure 2 As shown: the feeding and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com